A man who made own iPhone from the parts successfully succeeded in remodeling the headphone jack built into the iPhone 7 this time

Scotty Allen of former Google engineer who became famous became popular by opening up a business that creates an entire iPhone by hand using the parts bought in China / Shenzhen on his own YouTube, to embed headphone jack in iPhone 7 Succeeded. After a struggle for over four months, you can check the situation of getting iPhone 7 with headphone jack on the following movie.

Bringing BACK The iPhone Headphone Jack - in China - YouTube

"Can not attach headphone jack to iPhone 7?" "It is impossible"

Build iPhone with bought partsScotty Allen 's trouble, known for doing that, "There is no headphone jack on iPhone 7"

"I tried opening the headphone jack on the iPhone 7", a movie to drill a hole with a drillPublish on YouTubeAlthough it is done, of course, only to destroy iPhone 7. No one is adding a headphone jack.

In that case Allen who heads to Shenzhen from Hong Kong by train if he only has Jar.

I got the parts in Shenzhen and try to install a headphone jack on iPhone 7.

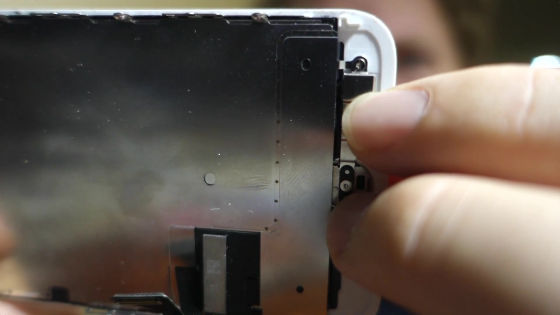

Allen who got used second iPhone 7 quickly removed the display unit. There seems to be a plastic part in the part where the headphone jack was.

According to the site of iFixit, it turns out that it is a part called "Barometric Vent".

Scrap parts of the headphone jack to be installed ......

I will try to do it, but it will not work due to lack of space.

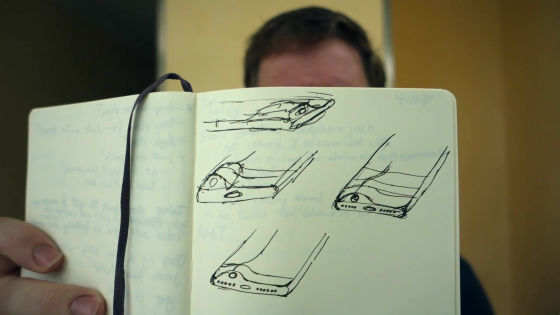

I also considered the plan to add it outside ... ...

After all, I wanted to put it inside.

So I will cut the case and make space.

Check the headphones jacks again.

It is even more frustrating.

I will cut the case.

Also cut headphone jack parts.

Push up obstructing parts of the obstructive Taptic engine ... ....

Battery also shifts to the limit.

I am clumsy, but somehow I made space.

However, with this positional relationship the display will not close.

The touch sensor parts seem to be disturbing.

Although it sniffs ......

By all means the display will rise.

Rushing into the second week since I came to Shenzhen.

Allen thinking of a good idea

Converting Apple's genuine Lightning connector to a headphone jackLightning-3.5 mm headphone jack adapterThe strategy of diverting it.

Allen who came to the Apple store to buy parts.

"It's not cheap but it's easy"

Cut the cable ... ....

Working.

However, I broke the connector part.

Purchase three parts again in the Apple store.

We also purchase electric wires for soldering.

I chose a material with high heat resistance.

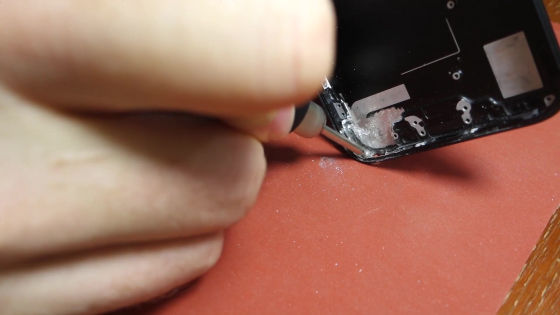

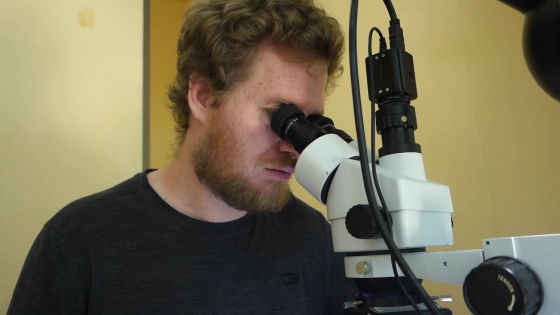

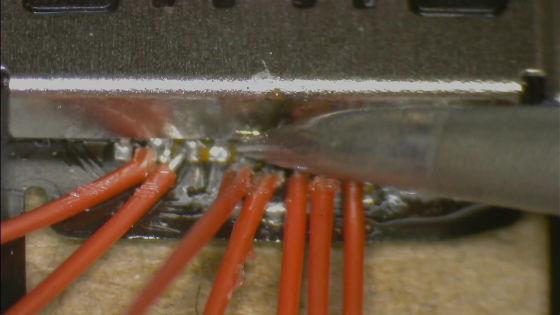

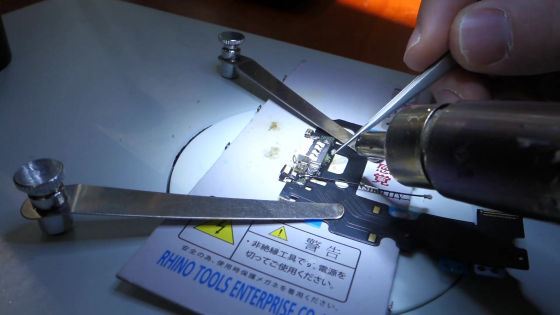

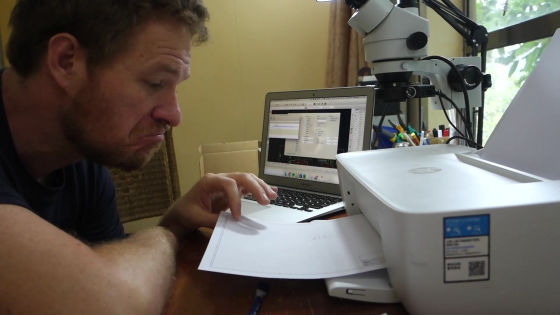

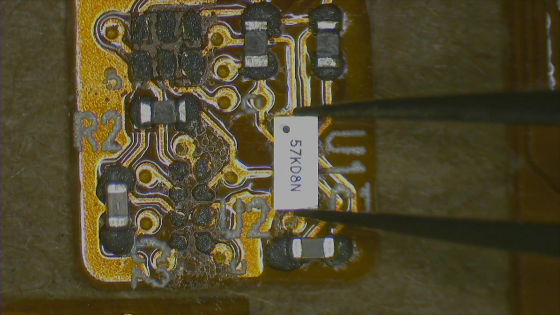

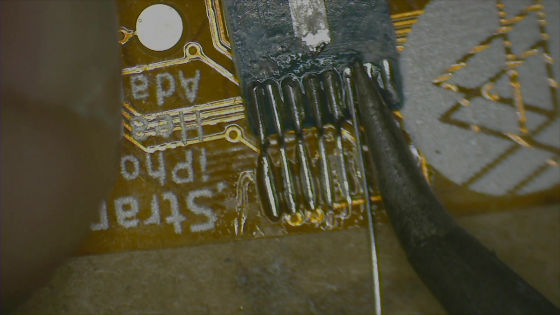

While peering through the microscope ......

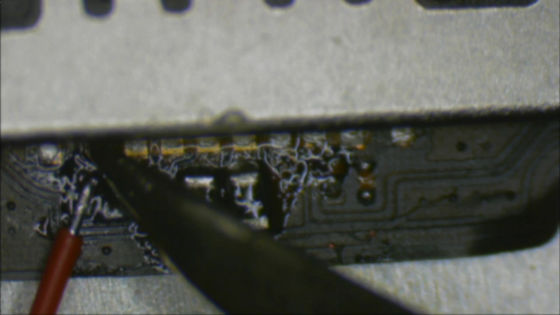

I will do soldering work.

3rd week.

Allen shows you a high-performance microscope.

How, purchase a high-performance microscope.

It seems that soldering work did not progress in cheap articles.

Allen satisfied with the performance of the new microscope.

Solder the wire more quickly.

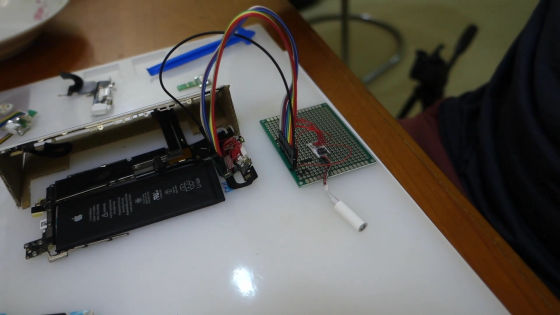

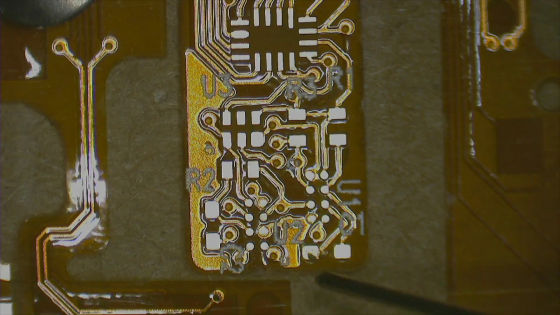

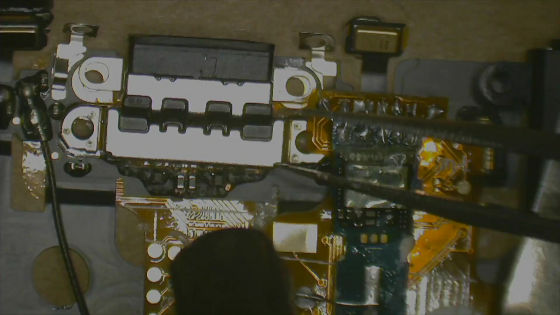

The circuit is completed on the universal board.

Connect to iPhone 7.

Attaching the earphone and ringing the sound ......

success.

Sound came out safely from the headphone jack.

5th week.

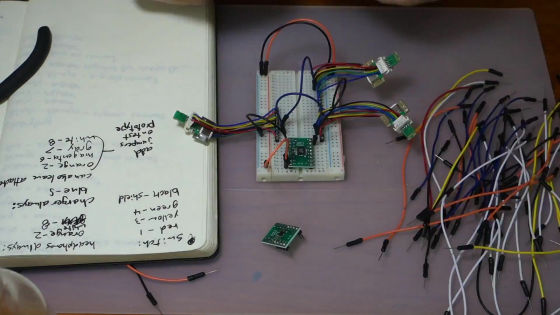

Allen after drinking with a friend. Telling the struggle, my friend recommended me to customize the original circuit to convert Lightning jack and headphone jack. If it is designed exclusively, it seems to be compatible with charging with a USB cable.

So that's why you bullboard and strangle to decide the circuit design.

It rushed in the 7th week.

A circuit that worked normally ......

I will place a special board for housing iPhone 7 case. First of all, I made a large item that was easy to solder and made it small things after I wash out the problems.

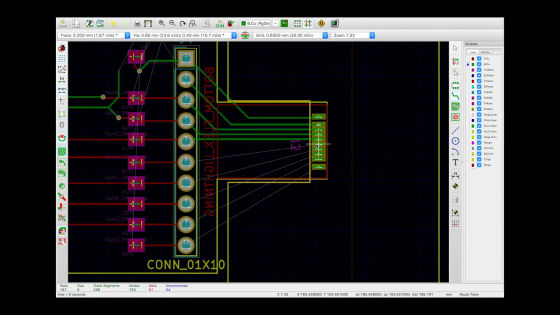

Over the course of a few days, create a circuit design drawing with special software.

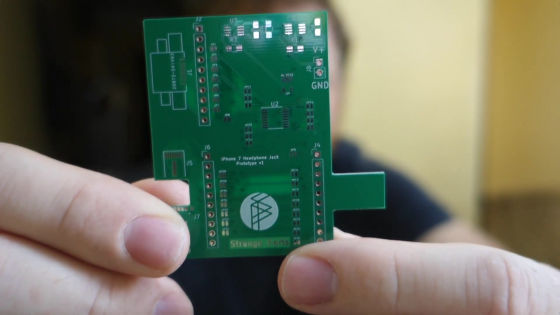

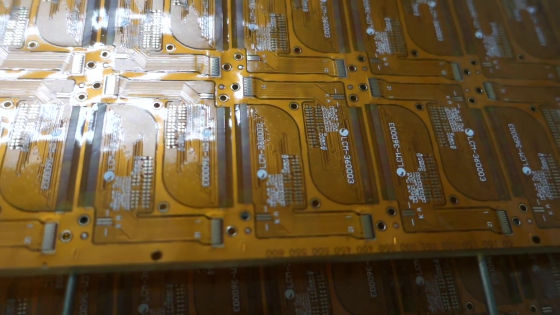

Sunday morning at 10:30. I received the circuit board I was ordering.

This is the original design board.

Work started immediately.

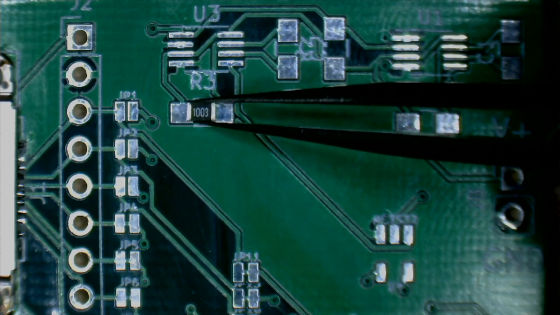

I will install capacitors and chips.

A prototype board is completed.

I test it in this state ... ...

Headphones did not work.

Allen suffered from investigating the cause.

After all, although there was a problem in the conversion adapter part, it was able to check the operation by returning to the conventional wiring.

Week 12. An attempt to attach a headphone jack to the iPhone 7 seems to be a long-term field that will last more than three months.

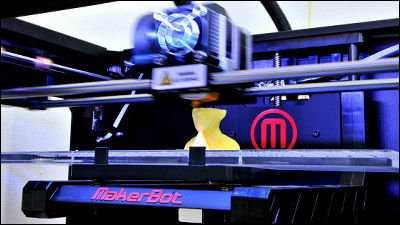

Allen who has bought a printer.

What is printing ... ...

A model of flexible type circuit. To check the size in advance, we are testing with parts printed on paper.

Week 13.

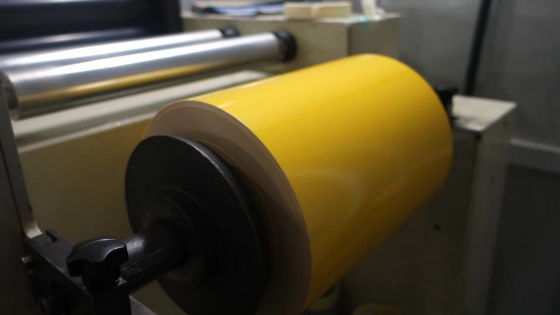

Allen succeeded in seeing a factory that manufactures flexible printed circuit boards.

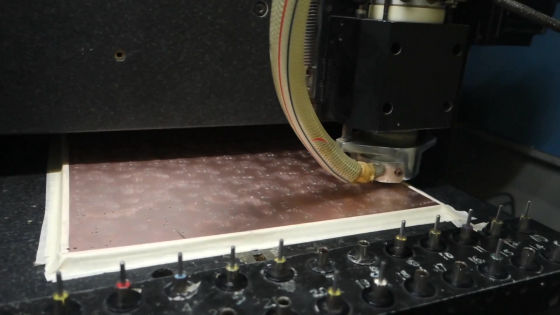

Rolled copper sheet.

Machine it into a circuit shape with a dedicated machine.

Machines can be exchanged automatically according to the circuit of different thickness.

The site where the circuit is printed has a terrible odor.

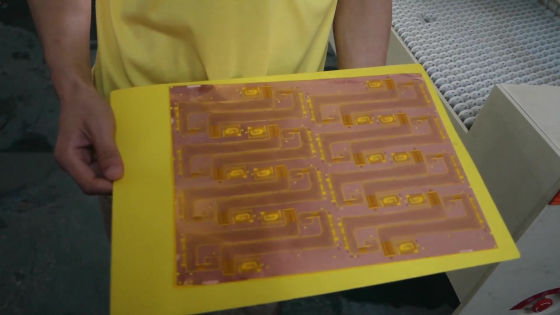

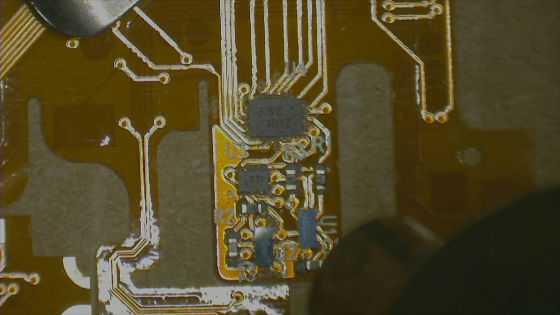

A thin substrate like a printed paper.

When peeling off the seal ......

Printed circuit boards were printed carefully.

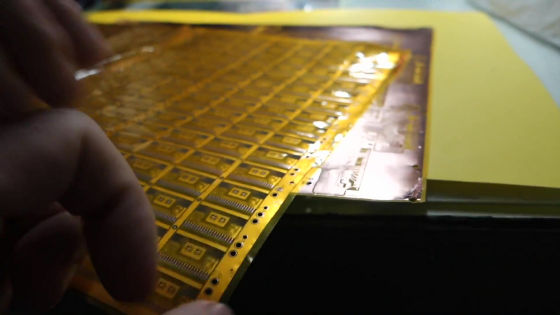

This is where you are printing characters on the board.

The name of the part was printed in white letters.

Crimp condition etc are tested.

Allen thus gets a flexible printed circuit board printed circuit of original design.

Because the pattern is printed ......

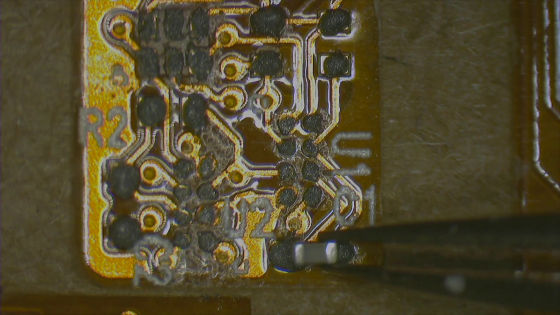

Apply solder paste. It is a strategy to install from small parts such as capacitors.

I also install chips.

Compact with a heat gun ... ...

Connection

Parts are also mounted on the back side carefully.

When the finished flexible printed circuit board is attached to the iPhone 7 ......

Safe, it worked.

Satisfied Allen.

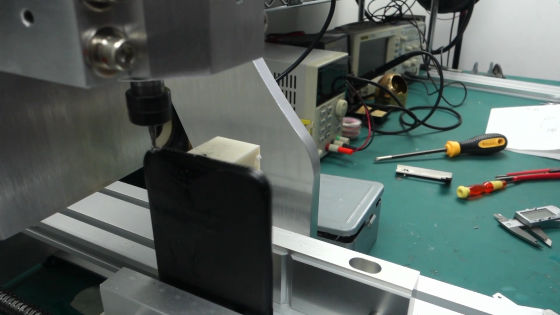

Next is the workshop which opens the hole exactly in the case.

I will give you a thorough discussion.

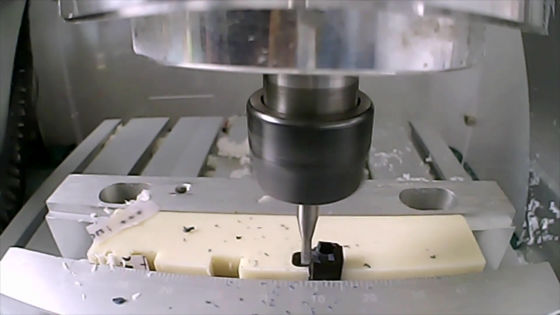

Simulation of cutting of CNC drill.

Enter G code ......

Start scraping. However, due to vibration, it seems that it does not go well.

Week 15.

After processing the fixture with the controller for Xbox 360, retry to drilling work.

This time it worked.

Good workmanship.

Next is the processing of the headphone jack connector.

Because it was plastic, it could be processed without difficulty.

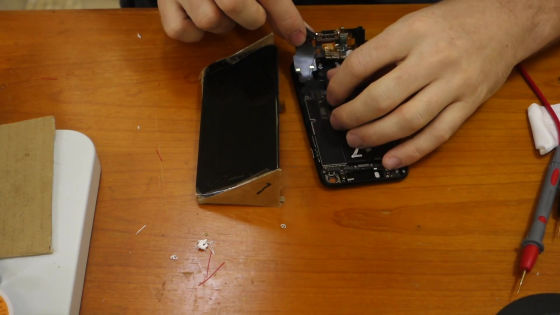

I put all the parts in the iPhone 7 case, and I got a little floating.

Cut the metal of the display unit.

I managed to fit it ... ...

A striped pattern appears on the display.

It seems I broke the display.

It will not work if the display is destroyed twice. I ceased.

Allen who leaks as "I want to quit". It seems to be quite depressed. But I can not stop it here. I will challenge it again.

Week 17.

Resume work.

It seems that each part is thinning by micrometer.

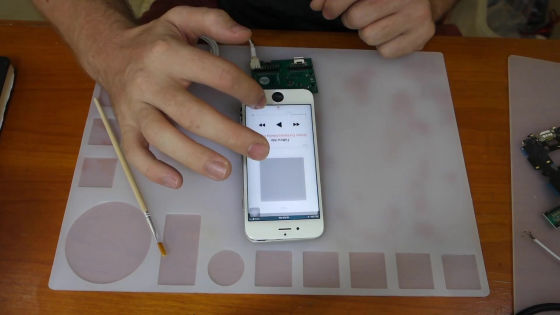

I also put printed boards brilliantly.

Allen installing the display.

I succeeded in integrally incorporating the headphone jack in.

When I play music ......

Sound leaks from the earphone.

There is no problem with charging. However, listening to music while charging can not be realized.

If you overlap iPhone 7 and iPhone 6 with headphone jack, you can see that the position of the headphone jack is different.

"It's a bit bigger hole, but that's not a problem," Allen said. I succeeded in attaching headphone jack to iPhone 7 brilliantly.

Finally, "One More Thing" from Allen

For those who think that "I'd like to attach a headphone jack to the iPhone 7", Allen said that he wrote the information on circuits and so onGithubI decided to publish at. I will accept questions as well.

The cost spent by Allen to attach the headphone jack to the iPhone 7 is thousands of dollars (hundreds of thousands of yen) in addition to the parts cost, including the microscope etc. It is a hat off to Allen's struggle to struggle to satisfy the desire of "wanting headphone jack" by spending that much.

Related Posts: