A person who replaced the iPhone with a USB Type-C port released a video of the procedure

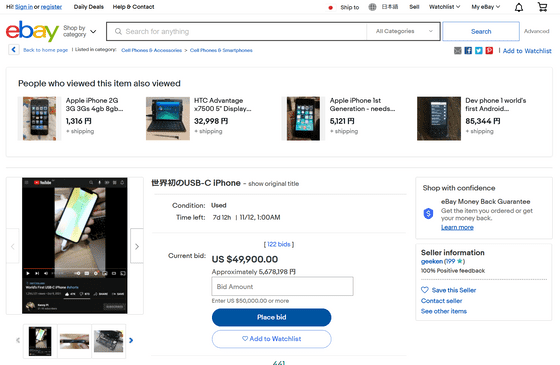

A person who installed a USB Type-C port on an iPhone using the proprietary Lightning standard has appeared. Ken Pillonel, a student in robotics, has released a video showing how successful port replacement was.

iPhone gets USB-C thanks to creative robotics engineer | AppleInsider

https://appleinsider.com/articles/21/10/11/iphone-gets-usb-c-thanks-to-creative-robotics-engineer

You can now, technically, build your own USB-C iPhone --The Verge

https://www.theverge.com/2021/11/2/22759704/usb-c-iphone-hack-mod-open-source-github-repo-ken-pillonel-design-video

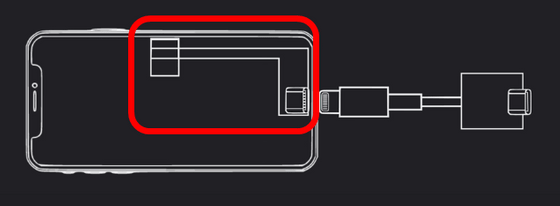

Pillonel's idea was to downsize the cable that connects Lightning and USB Type-C and the USB Type-C female-female relay adapter and put it in the iPhone.

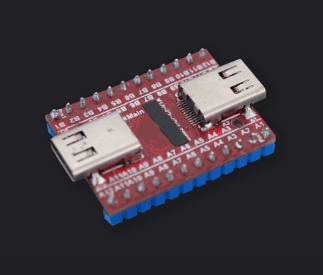

When Mr. Pillonel searched for similar products to make his own relay adapter, he found the following adapter, so he secured it.

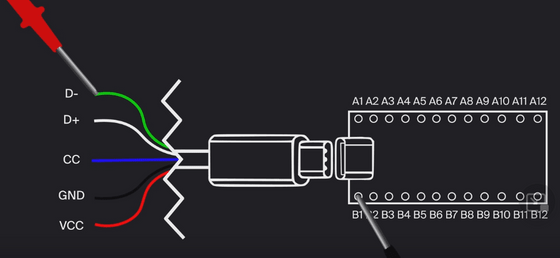

The next thing Pillonel did was check the continuity of the cable that connects Lightning to USB Type-C. Using a tester, he conducted a continuity check on 5 signal lines and all 24 pins, and clarified which line corresponds to which pin.

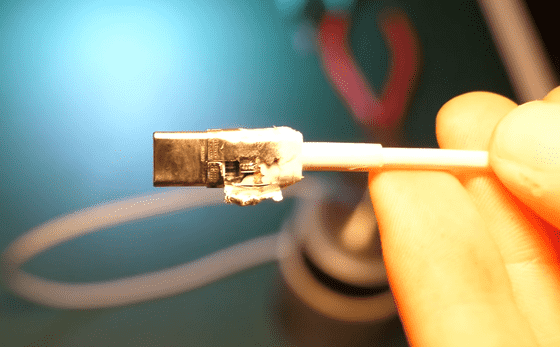

The next thing I did was check the cables on the Lightning side. To unravel the structure of the cable, Pillonel tried to pry open the connection of the Lightning cable, but Apple's unique structure called 'C91' was physically hard and difficult to disassemble.

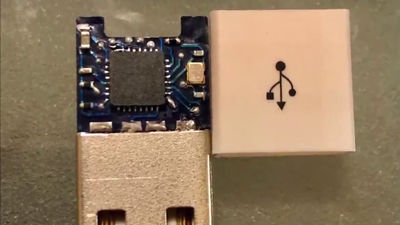

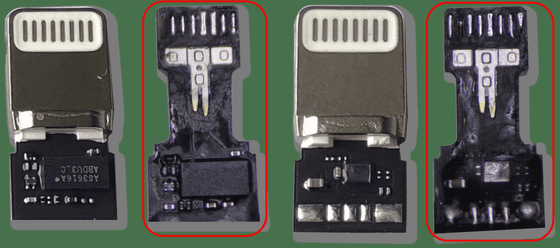

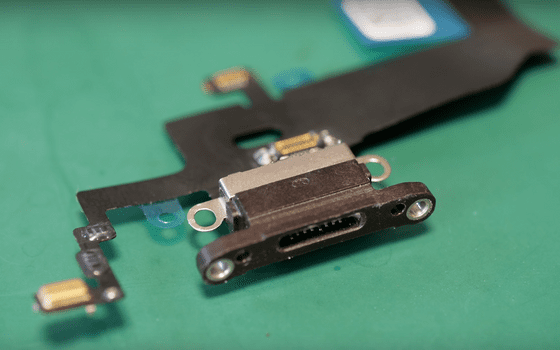

That's why Pillonel bought a third-party Lightning cable. The third-party cable has a different structure provided by Apple under the name 'C94', and it was easier to disassemble. The circuit part called 'PCB' taken out from the Lightning cable is as follows.

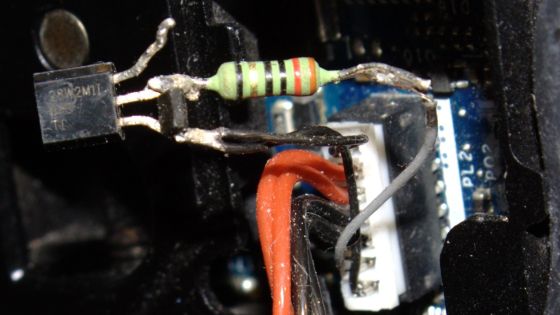

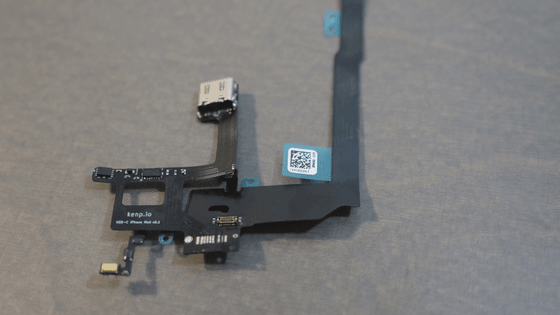

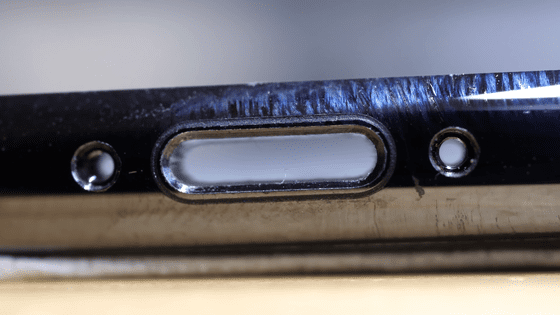

The next step is to remove only the Lightning port on the iPhone and connect the cable directly to the PCB. I knew that the parts around the Lightning port had the following shape, so Pillonel started to take it out.

The ones taken out are as follows.

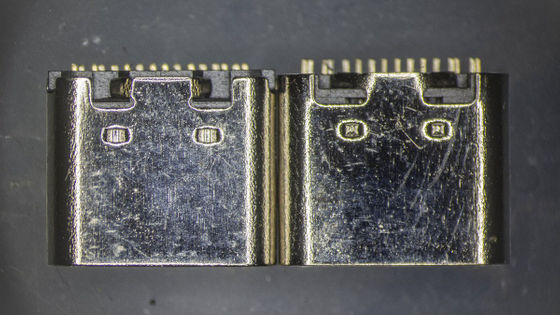

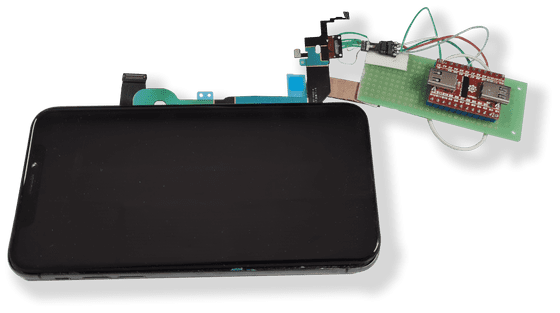

The state of actually removing the port and connecting it is as follows. The iPhone and PCB, and the PCB and USB Type-C relay adapter are now connected. In the image below, relay adapters are attached to both the left and right sides, but only one works originally. The other can be removed, Pillonel explains.

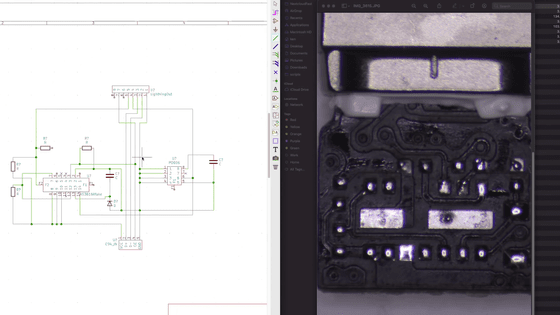

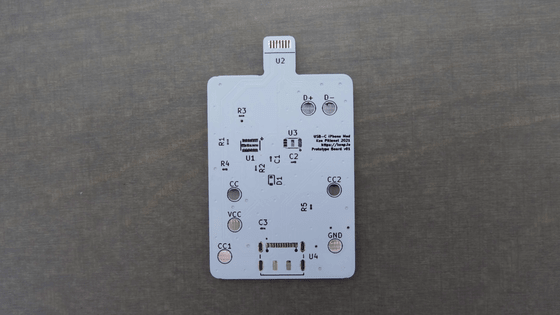

And Pillonel reverse engineered the C94 PCB to create a schematic ...

Make your own circuit.

Connected to iPhone. All you have to do is remove the cable from this circuit and install it inside your iPhone.

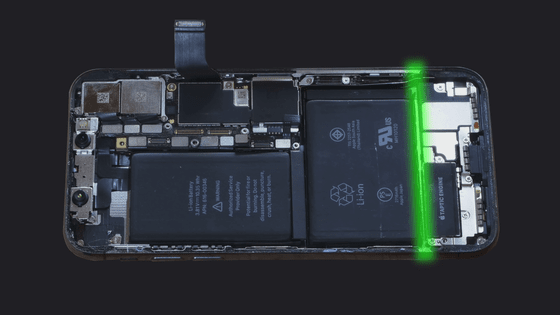

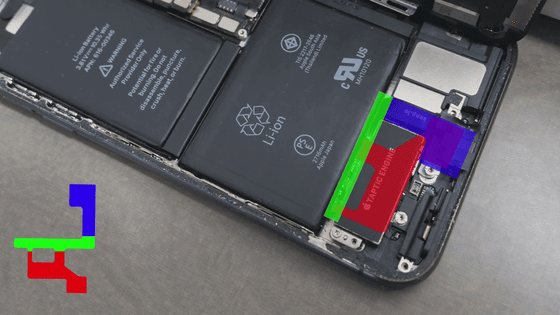

When Pillonel checked the contents of the iPhone, he found that there was a small gap between the

Therefore, he decided to make the circuit as thin as possible and place it in this gap.

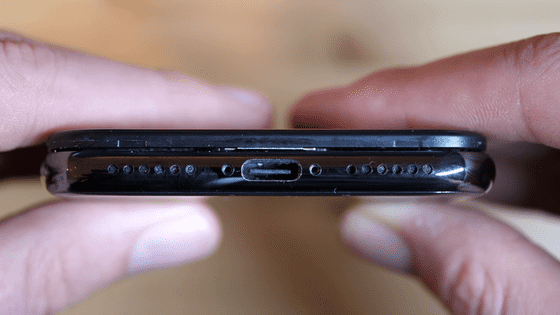

And the circuit created by Mr. Pillonel is as follows. Mr. Pillonel praises himself, 'The cable is gone and it looks like a genuine product.'

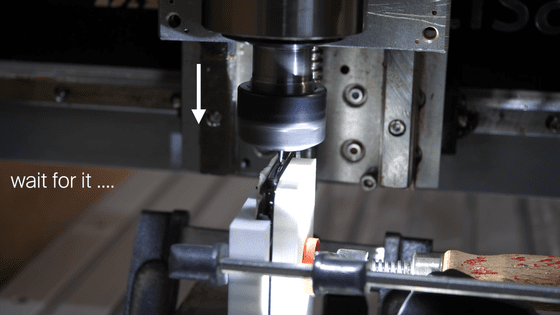

The next problem is that the hole in the iPhone frame for the Lightning port isn't big enough for the USB Type-C port.

There was a possibility that the glass frame would be crushed by simply shaving with a drill, so it worked well by shaving carefully while sandwiching the iPhone with other parts to disperse the force.

I also made a part that supports from the other side when the USB Type-C cable is inserted.

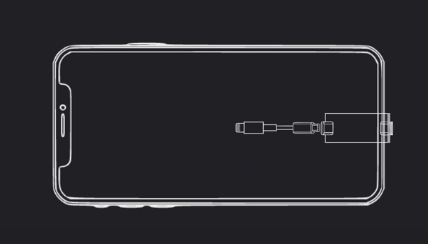

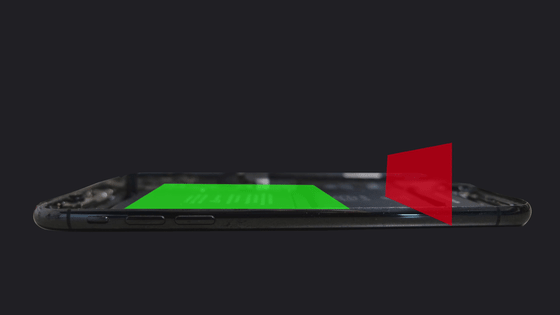

Finally, Pillonel attached the circuit he created to the iPhone as follows: The circuit is arranged in a narrow gap by bending the red part, the green part, and the blue part by 90 degrees each.

This completes the work of replacing the Lightning port with a USB Type-C port.

In addition, Mr. Pillonel

Related Posts: