If you assemble the iPhone from scratch using the parts purchased in Shenzhen, China, it will be like this

In the cyber town '

How I Made My Own iPhone – in China! | Strange Parts

https://strangeparts.com/how-i-made-my-own-iphone-in-china/

You can see how to buy parts in Shenzhen and assemble an iPhone from scratch in the following movie.

How I Made My Own iPhone --in China --YouTube

Shenzhen in China. It is the world's largest cyber town, with shops selling electronic parts that are dozens of times larger than Akihabara.

Scotty Allen, a former Google software developer who came to China nine months ago. Overwhelmed by the size of the smartphone market in Shenzhen, Allen suddenly wondered, 'Can I buy parts and assemble an iPhone from scratch?'

At McDonald's in Shenzhen, there are people repairing smartphones here and there.

There is a shop in the Dennou Building that repairs electronic devices such as smartphones.

Allen, who started buying parts at once, visited people who sell parts on the street.

A lot of iPhone cases are sold.

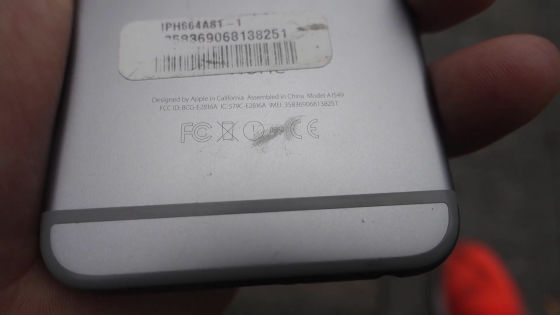

These are the parts taken from a used iPhone. It's genuine, but it's a second-hand product, so it doesn't meet Allen's goal of building a new iPhone.

A store in a cyber building. The glass case is for iPhone 7 Plus. However, if you look closely, there is no Apple logo.

When I told him I wanted a case for the iPhone 6s, the clerk started calling somewhere.

'How many do you want? Only one?'

I found a rose gold color iPhone 6s case at a different store. The clerk asked, 'Is there a button inside?'

The same question as 'How many do you want?'

The same reaction as 'only one?' By the way, it is very rare to sell separately in Shenzhen, and if you want a Lightning cable, you can get it in units of 100, '

In this way, I got a new iPhone 6s case with the film stuck on it.

In Shenzhen, there are a lot of iPhone cases that are obviously not made by Apple.

Allen noticed that the iPhone case he purchased had no laser engraving on it. So I went to another store.

When I told him, 'I want an iPhone case with American specifications, but there is no engraving,' he gave me the USA mark by laser processing.

I consulted with my Chinese friend Frank at McDonald's.

When I told him that I wanted to make the display part of the iPhone from scratch, he said 'glass panel' ...

'LCD with digitizer'

'Backlight' is necessary.

Frank's guide came to a shop that repairs iPhones. It's very difficult to get a new LCD for the iPhone, so I decided to remove the part from the broken used iPhone display module and combine it with other new parts.

Remove the glass panel from the iPhone display module with a fishing line.

I was able to take out the LCD.

Take out a special knife ...

Carefully peel off the attached film.

A sticky roller removes dust and dirt from the surface.

Take out a new iPhone glass panel ...

Paste it on the LCD.

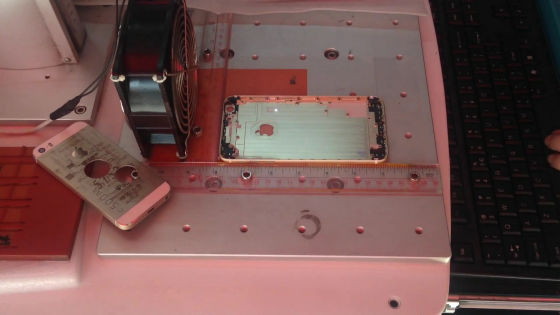

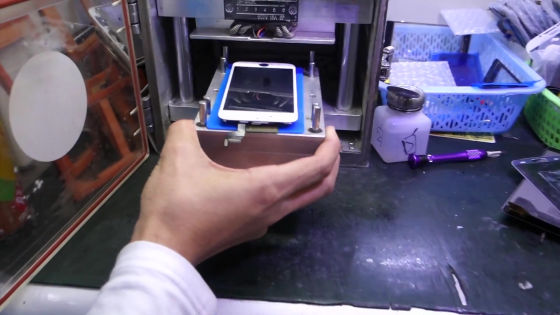

Now put the display in a special machine.

It is a machine that integrates a glass panel and an LCD by heating while evacuating.

It stuck firmly. However, I found a place with bubbles.

To another chamber.

This is a special machine called 'foam removal desk' that sucks out air bubbles.

Completion of a new display module for iPhone without bubbles.

Next, install a new backlight.

Careful work is required to install the backlight.

After installation ...

Connect with a dedicated tester.

The display turned on brilliantly.

Touch operation is also OK.

Get the display with this.

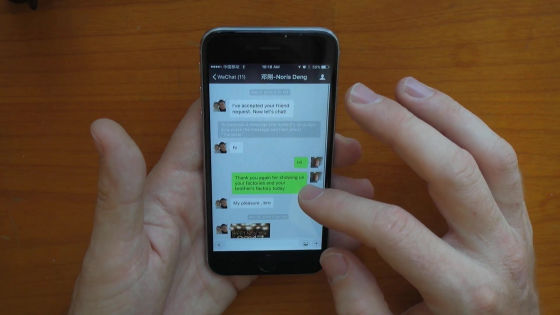

In Shenzhen, most stores pay cash, but mobile payments using the Chinese SNS application 'WeChat' are also widespread.

Copy the QR code of the clerk ...

Enter the amount.

Operate Touch ID to complete the remittance.

'Every time'

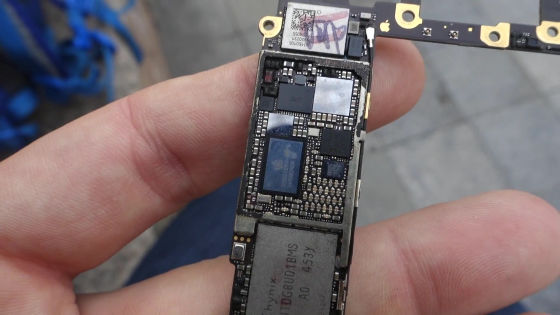

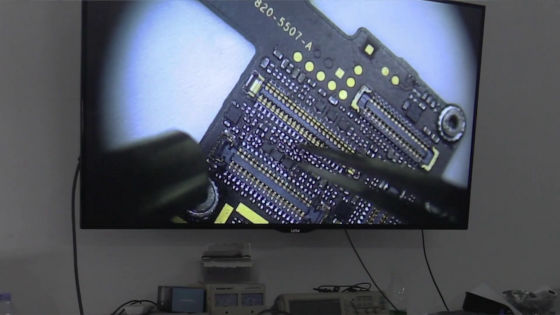

The next item to be procured is the 'logic board.'

The logic board with SoC and memory, which can be called the 'iPhone brain', is the most new and difficult to obtain part.

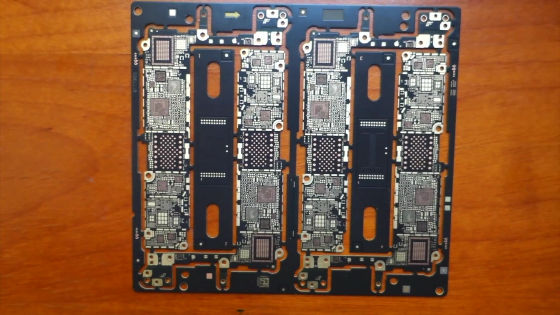

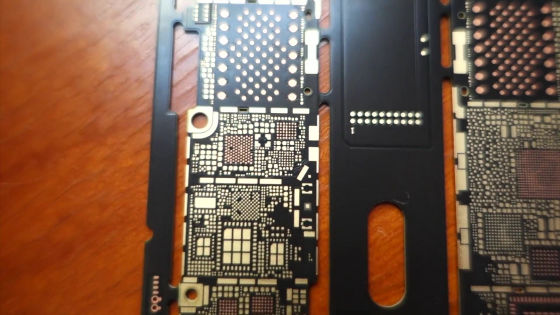

Allen succeeded in obtaining the board of the logic board.

It is a set of four logic boards, and it is thought that it is a part that came from a factory in China that manufactures iPhones.

There are no chips on the board.

You can get all the chips at the Shenzhen shop, so let's make a logic board from scratch.

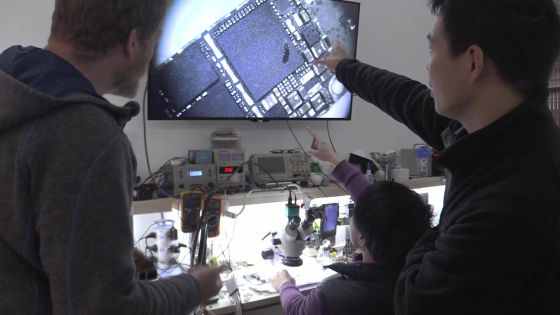

Allen decided to consult with a vocational school instructor who teaches smartphone repair techniques.

Allen receives an explanation of repair technology.

Manually replacing extremely small parts requires a high level of skill.

According to the teacher, 'It is technically possible, but extremely difficult.'

Allen decided to give up on making his own logic board.

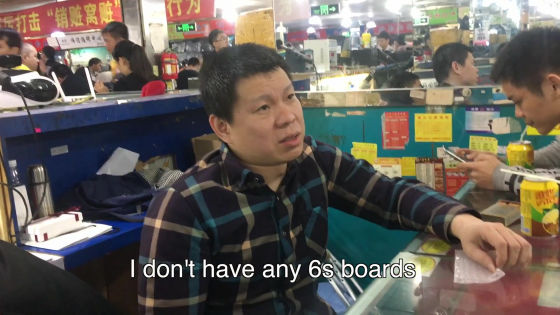

Return to Shenzhen's Cyber Building.

Unfortunately, the logic board for the iPhone 6s is out of stock.

It seems that it will arrive by the end of the Chinese New Year.

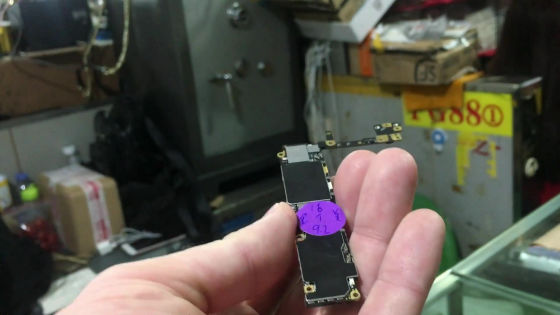

I hit another store and found the logic board I was looking for.

I couldn't test the operation, but the female clerk said, 'I guarantee the contents.'

In this way, 'used logic board'

'Apple battery' available everywhere

'Display' is complete.

Allen checking the operation. Connect each part.

The Apple logo was displayed.

Allen smiles unintentionally.

Touch operation is possible, but the operation is troublesome because there is no home button.

However, trouble occurred. When you start the compass app ...

I couldn't recognize the direction well. Apparently the logic board is out of order.

Since it is within the warranty period of 'within 3 days', when I visited the store to ask for a refund, I heard that the refund was processed via WeChat. After that, he answered, 'Come at 5 o'clock. I will bring new things.' Allen describes Shenzhen's deal as a world of verbal promises with no receipts.

When I returned to the store at 5 o'clock, the woman was arranging a new logic board. Successfully replaced the logic board.

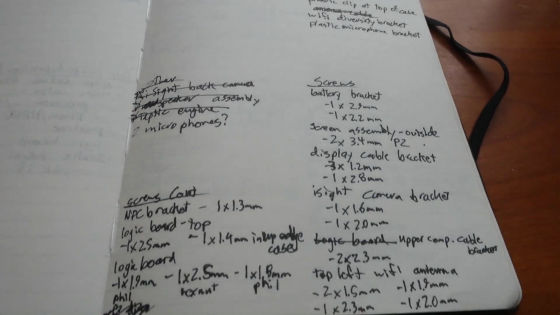

Allen tells the camera how difficult it is to collect the rest of the parts, 'it's hard to collect small parts such as camera modules, cables, and screws.'

I have written down the necessary parts in my notebook, so I will collect them from stores all over Shenzhen.

However, Allen is super lucky.

When I first entered the store and told him that I wanted a set of parts needed for the iPhone 6s, he said, 'I have them all.'

The camera module

Lightning connector and cable ……

A set of screws for iPhone 6s

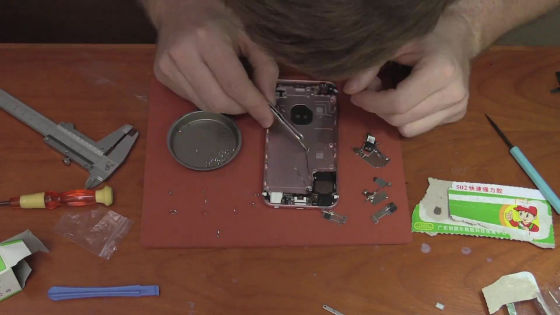

Allen, who has all the parts, is finally ready to start the assembly work.

Start detailed work on the workbench.

We will clear difficult parts by relying on the information on the net.

In the middle of work ...

Trouble.

It turns out that there is no 'click feeling' of the button.

Work got stuck.

'I bought this part yesterday, but it doesn't feel like a click.'

The clerk picks up Allen's iPhone case and checks 'Which one'.

'That's it' from a pile of parts ...

I took out the parts.

What was missing was a small resin part at the tip of the tweezers.

When I put it on, a click feeling appeared.

Allen, who regained the click feeling, resumed work.

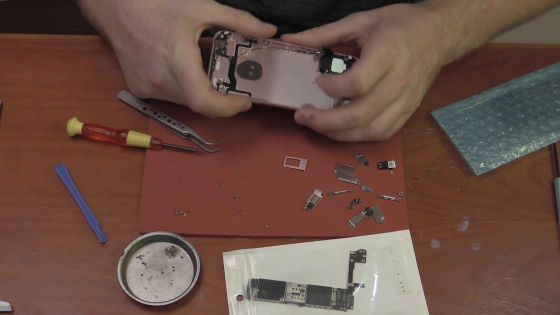

I've reached the point where I can install the battery.

The goal is right in front of me.

A camera module etc. is attached to the display side.

Assemble and turn on the power.

The iPhone worked fine.

Allen with a big smile.

'I didn't think it would be completed at first ...' said Allen with deep emotion.

Allen, who built the iPhone from scratch, said he was able to experience the beauty of Shenzhen's 'ecosystem.'

It is said that the Shenzhen ecosystem is very good, as it can repair such broken parts in a blink of an eye by extracting only usable parts and combining them with new parts.

And Allen's 'One More Thing'

I have an iPhone 6s box.

A set of cases, earphones, charging adapters, cables, manuals, etc. are also available in Shenzhen's Cyber Street.

Put the assembled iPhone 6s in ...

Complete.

It seems that the cost of the self-made iPhone 6s (16GB model) that I made by buying all the parts by myself was about 300 dollars (about 32,000 yen) for the parts.

Related Posts: