Solar power industry faces chronic labor shortage, giant robots are the key to improving the situation

The solar power industry is developing rapidly, and due to the fall in the cost of solar panels, the United States recorded 25 times more solar power generation in 2020 than in 2010. However, large-scale solar power generation facilities require a large number of solar panels to be installed in a large space with no obstruction of sunlight, which requires a considerable amount of labor, including long commute times and heavy labor, and serious labor shortages have become an issue in the industry. Giant robots that build facilities are expected to play an active role in solving this problem.

Robotic solar workers could solve the industry's labor shortage - Fast Company

Robotics engineer Banks Hunter described his amazement when he toured a solar farm under construction. The facility was installing about 2 million solar panels over an area the size of tens of thousands of football fields, with hundreds of workers moving up and down rows of panels. The installation process took six months to complete, and Hunter said, 'This incredibly manual process just seems insane. I don't see how this process will ever stabilize for the energy transition.'

Hunter worked with his former classmate from Massachusetts Institute of Technology, engineer Max Justitz, to improve solar power plants. As the two talked to solar power companies, they found that most of them were 'overwhelmed with demand for new projects and struggling to secure labor.' So Hunter and Justitz founded a company called Charge Robotics to automate some of the solar power plant construction process.

The installation of most large-scale solar power plants is divided into four steps. First, steel piles are driven into the ground to form the foundation. Next, cardboard boxes containing solar panels are lifted by forklift and distributed to each installation site. The work itself is simple, but when a facility covers an area of 40 square kilometers, just distributing the panels is hard work. The third step is to screw the frames that hold the panels in place one by one. Finally, workers walk around the site attaching the panels to the frames.

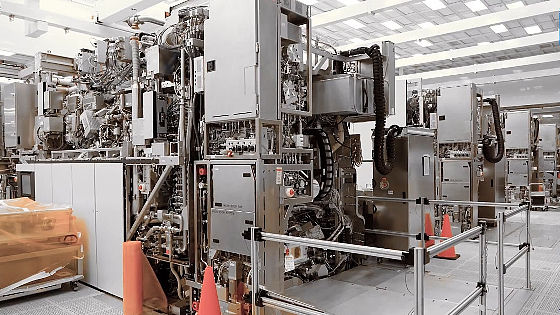

To carry out the second and subsequent steps, Charge Robotics has created a portable factory robot that can move around the facility. The base is fixed as usual, but the robot, which can mount solar panels and frames on it, moves around like a shipping container, and delivers the assembled product to each location.

Hunter explains that the system, called 'Sunrise,' is able to complete solar panel installation tasks that previously required hundreds of people with just an operator, driver, and a handful of technicians. It's also possible to use it in conjunction with workers on larger sites, without making major changes to traditional methods, and it's expected to double installation speed.

'Let's be honest, construction companies are right to be wary of new technology. We see a lot of people trying to sell robotics and new technology on construction sites, and a lot of it doesn't work. In this case, we're pleased that Solv Energy, a major solar installer, was so impressed with our system that they decided to partner with us,' Hunter said.

Related Posts:

in Note, Posted by log1e_dh