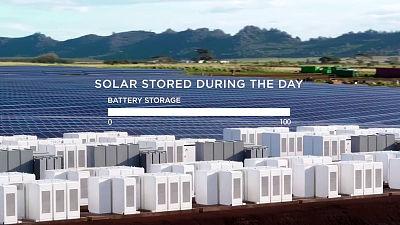

Introducing a heavy-duty robot that automatically helps install huge solar panels

In order to obtain a large amount of electricity from sunlight, a large number of solar panels need to be installed in a vast area. However, it is costly because it requires a considerable amount of labor to transport and install a large number of heavy and large solar panels. The co-founder of robotics company

Launch HN: Charge Robotics (YC S21) --Robots that build solar farms | Hacker News

https://news.ycombinator.com/item?id=30780455

The robots developed by Charge Robotics can be seen below.

Charge Robotics Staging Demo Uncut --YouTube

A heavy equipment type delivery vehicle that carries stacked solar panels. No one is in the cockpit.

Next to the cockpit, there was a worker checking the system with a notebook PC. Two cameras are attached side by side like both eyes on the delivery vehicle, and it is said that it is performing self-position estimation, environmental map creation, and object detection.

The solar panels were placed between the pillars that erected vertically to the ground. Another robot will fix this placed solar panel to the frame.

You can see the whole picture of the self-driving robot that was carrying the solar panel in the following movie.

The robot looks like this. The tip of the arm has something like a forklift claw.

Pull out the luggage loaded in the back of the truck ...

First, carefully carry it to the front side of the truck bed.

Then lift one of the two luggage ...

Gently lower it to the ground.

'With the physically demanding and inefficient process of workers manually installing thousands of solar panels, we should have a better way to build solar power,' Charge Robotics said. Thinking and realizing that advancing automation is the way to go in the future. '' Since the construction of solar panels works in a semi-structured environment, that is, on flat soil, there are very few special cases, and autonomous vehicles. I think that it is the 'homework version' of. With the current manual construction, the rate of breakage when installing solar panels is about 0.1% to 0.5%, and robots must be below this value, but autonomous vehicles Compared to the strict performance requirements of the industry, it is an easy hurdle to target. '

Unlike the United States, which has a lot of vast flat land, in order to generate large-scale solar power in Japan, which occupies 75% of the mountainous area, we will open up rural mountainous areas rather than the rooftops of urban residential and commercial facilities. It is more efficient to install a solar panel. As a result, Japanese solar panels are often installed on mountain slopes, so introducing a robot like Charge Robotics in Japan may be a higher hurdle than in the United States.

Related Posts: