Is it true that sand will run out?

Sand can be found all over the world, whether in mountains, oceans, or rivers, but

Is the World Really Running Out of Sand? — Practical Engineering

https://practical.engineering/blog/2024/10/1/is-the-world-really-running-out-of-sand

Is the World Really Running Out of Sand? - YouTube

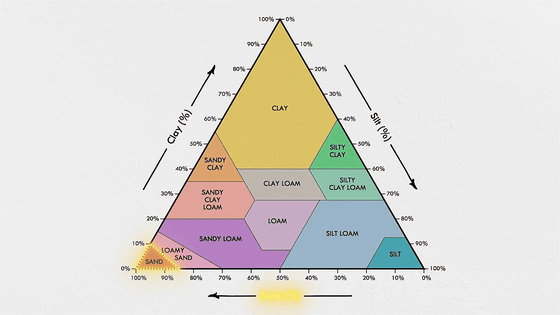

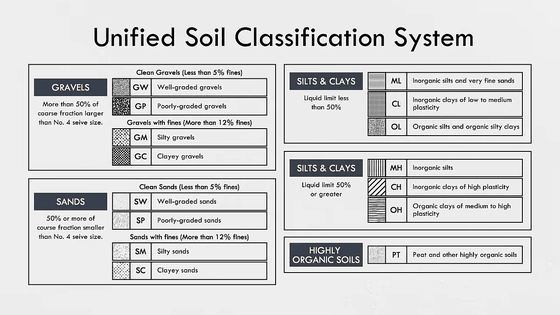

According to the soil texture triangle , a classification system created by the United States Department of Agriculture based on the relative fractions of clay, silt, and sand, sand is 'a granular material that is at least 85% sand.'

In

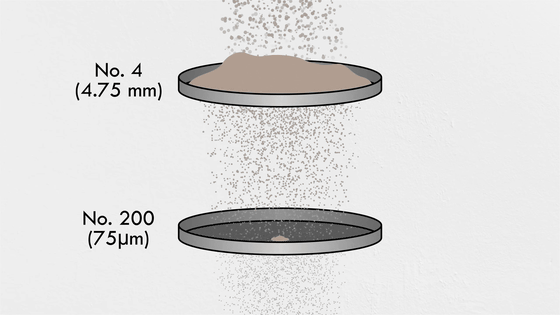

In this classification system, sand is defined as 'sand having at least 50% of the coarse particles passing a sieve with openings of 4.75 mm and less than 50% of the coarse particles passing a sieve with openings of 0.075 mm.'

Sand is used as a material for a variety of substances, including glass, semiconductors, optical fibers, filters, and abrasives, and is above all an essential material for concrete, which is indispensable for the construction of modern cities.

'It is impossible to overemphasize the importance of concrete and how much humanity uses it,' Hillhouse said. Concrete has many advantages over other building materials, including the fact that it can be molded into any shape imaginable, is very low-cost yet durable, and can be made from materials available anywhere in the world, such as water, cement, gravel, and sand.

These properties of concrete allow humans to build durable structures that can last for generations.

Most of the raw materials for concrete are mined and used as is, often close to the site of use, because transportation costs make up a large portion of the cost of sand for construction purposes.

The best sand for concrete is that mined from rivers, but mining sand from rivers is a sensitive issue as it can lead to changes in the nature of waterways.

Sand is also not evenly distributed around the world, and it is a non-renewable resource: geological processes produce sand much slower than humanity can use it, giving rise to the myth that we will eventually run out of sand.

However, sand can be artificially created, and the process is not that complicated: First, large rocks are broken into smaller pieces using a hammer.

The sand is then sorted by size using a sieve to remove any oversized or undersized particles. Processing artificial sand has many advantages over mining natural sand, such as the use of existing gravel from quarries and crushing operations, and the mining process can be carried out away from rivers and streams, reducing the impact on the environment.

In addition, the use of artificial sand can increase the strength of concrete.

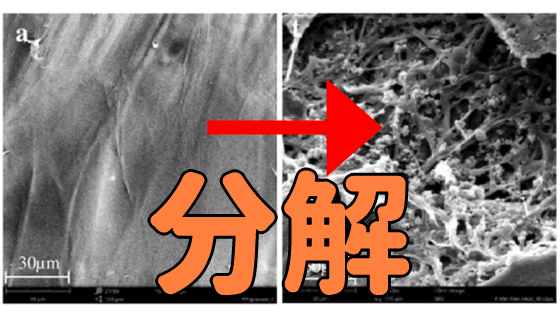

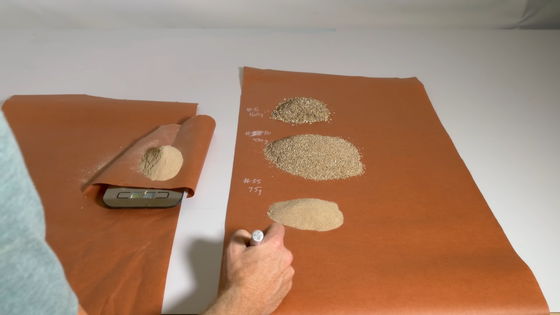

When natural sand is examined under a microscope, it is rounded, spherical and smooth.

In contrast, artificial sand is characterized by its sharp edges.

Put the same amount of natural sand (right) and artificial sand (left) into two cylindrical containers and lift the container. There doesn't seem to be much difference, but you can see that the natural sand spreads out more than the artificial sand because the particles have less friction. 'You can see intuitively that the concrete made with artificial sand is stronger,' said Hillhouse.

In addition, concrete was made using both natural and artificial sand, and its strength was tested. The results showed that the concrete made with artificial sand was three times stronger than the concrete made with natural sand.

However, concrete has several other desired properties in addition to strength. For example, concrete is liquid before it hardens, but it is a heavy object with a density about 2.5 times that of water, so it is very hard and molding it is very hard work. Therefore, depending on the raw materials of concrete, the liquid concrete before it hardens can become too hard, causing hoses to become clogged and air bubbles to become trapped, resulting in a decrease in quality after it hardens. This property of concrete is called 'workability.'

To improve the workability of concrete, you can use more water. However, the more water you use, the weaker the concrete will be. The key here is the shape of the sand particles.

When concrete is made with artificial sand, it is obviously less workable. To make concrete made with natural sand and concrete made with artificial sand have the same workability, it is said that the concrete made with artificial sand needs to add about 30% more water.

Furthermore, when the strength of each type of concrete was tested, the concrete made with artificial sand was 10% weaker than the concrete made with natural sand.

In other words, when considering workability, using sand with less friction, such as natural sand, rather than artificial sand will result in higher quality concrete.

However, Hillhouse said, 'Concrete is like baking bread; different ingredients produce different finishes. Just as local bread recipes have evolved based on the availability of local ingredients, the construction industry has developed ways to achieve good structural properties in concrete using a variety of local materials. As with many things in engineering, the real challenge is cost.' He pointed out that the fundamental problem is not the difference between natural and artificial sand, but the cost.

In some cases, the cost of transporting sand is higher than the cost of mining it. This is because sand is heavy and large quantities are required. No matter how high quality it is, the cost of transporting it from a long distance is too high. In addition, the cost of sand mining is rising due to stricter environmental regulations around the world.

With this in mind, Hillhouse pointed out that 'sand is not running out, it's just that sand is more expensive than it used to be. 'He added, 'There's a lot of change happening in the construction industry, and the demand for materials like sand and gravel has grown significantly. But I don't think it's fair to say that there's a shortage of these materials around the world. We're just becoming more aware of all the costs of sourcing materials and thinking more deeply about how that impacts our future and the environment.'

Related Posts: