The mystery of 'Why does ancient Roman concrete boast durability of 2000 years?'

The people of

Hot mixing: Mechanistic insights into the durability of ancient Roman concrete | Science Advances

https://www.science.org/doi/10.1126/sciadv.add1602

Riddle solved: Why was Roman concrete so durable? | MIT News | Massachusetts Institute of Technology

https://news.mit.edu/2023/roman-concrete-durability-lime-casts-0106

We Finally Know How Ancient Roman Concrete Was So Durable: Science Alert

https://www.sciencealert.com/we-finally-know-how-ancient-roman-concrete-was-so-durable

Concrete used by ancient Romans with advanced building technology is called Roman concrete , and while the lifespan of reinforced concrete widely used in modern times is about 50 to 100 years, even after 2000 years It has the durability to maintain its structure.

Below is a picture of the ancient Roman temple Pantheon , which was actually built from 118 to 128. The building and dome are built on a foundation of Roman concrete, and despite the fact that the foundation and dome have hardly been repaired, they still retain their original appearance even after about 2,000 years have passed.

Previous research on Roman concrete has shown that mixing volcanic ash with the raw material promotes the

Roman concrete boasting durability for 2000 years had increased strength due to seawater corrosion - GIGAZINE

Newly, an international research team led by MIT conducted research focusing on small lumps of lime called 'lime crust' found in Roman concrete. Admir Masic , associate professor of environmental engineering at MIT and researcher of Roman concrete, said, ``Ever since I started working with ancient Roman concrete, I have been fascinated by its characteristics.'' ``Lime crust is modern 'Why is it present in the concrete of ancient Rome, if it is not found in the concrete structures of ancient Rome?'

So far, it has been thought that lime crust is simply due to the use of poor raw material mixtures or low quality raw materials, but Mr. Masic said he had doubts about that idea. “If the Romans strived to make superior building materials according to detailed recipes optimized over centuries, why didn’t they focus on mixing the ingredients well?” says Masic. He said that he conducted research thinking that the lime crust should have some meaning.

The research team analyzed Roman concrete samples taken from ancient Roman ruins using scanning electron microscopy , energy dispersive X-ray spectroscopy , powder X-ray diffraction analysis , and confocal Raman imaging .

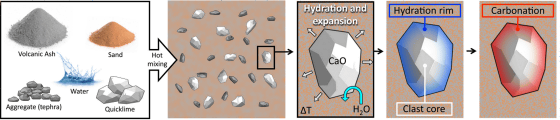

The conventional hypothesis was that the lime used in Roman concrete was slaked lime (calcium hydroxide) . However, analysis of the lime crust suggested that the lime contained in Roman concrete was quicklime (calcium oxide) or both slaked and quicklime.

by Paul VanDerWerf

The research team believes that the use of quicklime instead of slaked lime caused an exothermic reaction, and that Hot Mixing was the key to the durability of Roman concrete. “The benefits of hot mixing are two-fold,” Masic says. This higher temperature, in turn, accelerates all the reactions, resulting in much faster curing and setting times, enabling much faster construction.”

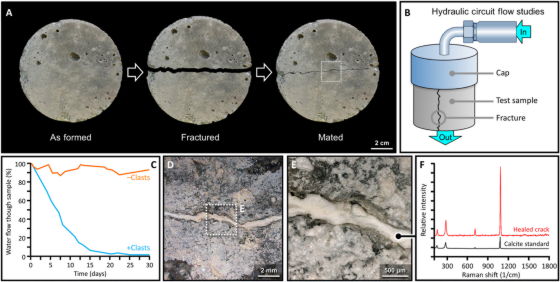

It is hypothesized that during the high-temperature mixing process, the lime crust develops into a characteristic brittle nano-particle structure, which gives Roman concrete its self-healing ability. Nanoparticle structures infiltrated into cracks are thought to react with water and recrystallize as

In order to investigate this hypothesis, the research team actually created concrete with the raw material of Roman concrete suggested this time and the raw material used for modern concrete. After intentionally creating cracks and then pouring water, it was confirmed that the cracks were repaired within two weeks in the concrete made with the quicklime mixture.

Based on this result, the research team is working on commercializing environmentally friendly concrete as an alternative to current concrete. “It is exciting to think that such a durable concrete building material can not only extend the useful life of buildings, but also improve the durability of 3D printed concrete building materials,” Masic said. .

Related Posts:

in Science, Posted by log1h_ik