Ferrock which is stronger, flexible, cheaper and more CO2 absorbing than concrete

by Samuel Zeller

"Cement" is a powder for mixing with water or a solution to make it harden when making concrete, mortar and the like, and its production amount is 4.1 million tons worldwide. When making cement and mixing cement and water to make concrete, a lot of carbon dioxide (CO 2) is released, and although there is environmental impact, it is still in the world in terms of strength and durability Concrete is used in. " Ferrock " has the advantages of this concrete, but it clears the problem.

Ferrock: A Stronger, Greener Alternative to Concrete?

https://buildabroad.org/2016/09/27/ferrock/

David Stone of the University of Arizona who "discovered" Ferrock. In a doctoral course of environmental chemistry, he seems to have come by chance while seeking ways to prevent iron from getting rusty and hardening.

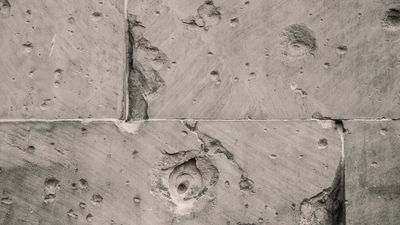

The name "Ferrock" shows its composition and is mainly made up of waste steel dust and silica, which is usually discarded. After drying, like concrete, it can not be returned to liquid, but it retains the hard rock-like character.

Compared to Portland cement , which is commonly called "cement" around the world, the strength of Ferrock is 5 times. It has the flexibility to withstand shrinkage, and it is characterized by being even stronger in salt-watery environment. Also, when drying, CO 2 is absorbed instead of being discharged, and it combines.

It seems like this is a very useful building material, but if it is found that waste steel dust is useful as a building material, the price that was no better than the free shipping price would be expected to rise exponentially, which would increase the manufacturing cost of Ferrock It is a skeptical view of the cement industry as to whether it can not be used on a large scale like concrete.

Related Posts:

in Note, Posted by logc_nt