A processing method that makes wood 23 times harder than usual is born, making it possible to create wooden knives that can cut 3 times more than stainless steel knives

In a paper published on October 20, 2021 in Matter, a peer-reviewed scientific journal related to materials science, a processing method that makes wood 23 times harder than before was announced. Making knives from hardened wood processed this way will result in knives that are three times sharper than stainless steel knives.

Hardened wood as a renewable alternative to steel and plastic: Matter

Researchers make hardened wooden knives that slice through steak

https://phys.org/news/2021-10-hardened-wooden-knives-slice-steak.html

Most eating knives are made of stainless steel or ceramic, but both are artificial materials and must be forged in a hot pot, which is not environmentally friendly. There are also plastic knives, but they are blunt and there is a worldwide movement to reduce plastic in the first place.

A research team aiming to develop 'environmentally friendly knives' that can replace these knives, by making wood 23 times harder than usual, it can replace stainless steel knives that are sturdy and sharp. I made a knife.

The lead author of the research paper is Ten Lee, a materials scientist at the University of Maryland. 'The wooden knives presented in the study can easily cut medium-baked steaks and perform as well as knives that can be placed on a regular dinner table,' he said.

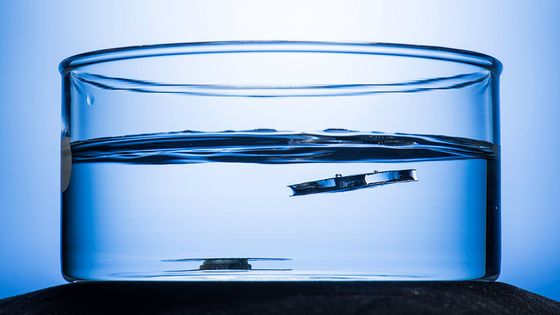

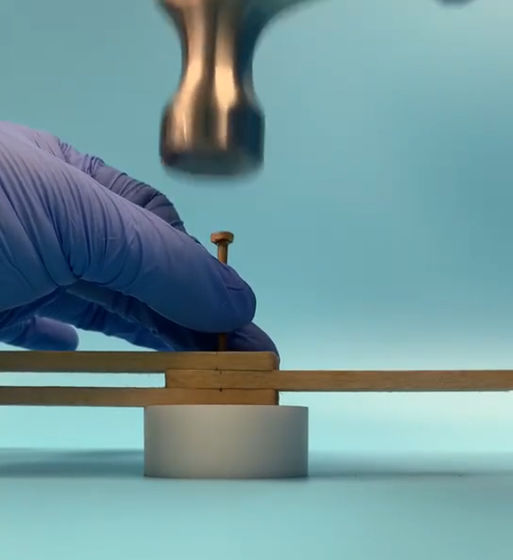

The research team has succeeded in creating not only knives, but also wooden nails that can be used in the same way as traditional stainless steel nails. In the experiment, we succeeded in striking three boards using wooden nails without damaging the nails, achieving 'sharpness that penetrates the boards' and 'sturdiness that does not break even if they are striking'. Has been proven. In addition, wooden nails have the advantage of being 'resistant to rust.'

General wood processing has been practiced for centuries. When preparing wood for furniture and building materials, it is said that there is some bounce after molding because the wood is processed only by steam or compression. Therefore, natural wood has the disadvantage of being cumbersome to use. 'Cellulose, the main component of wood, has a higher strength-to-density ratio than most processed materials such as ceramics, metals, and polymers, but existing wood usage offers most of its potential. It wasn't done. '

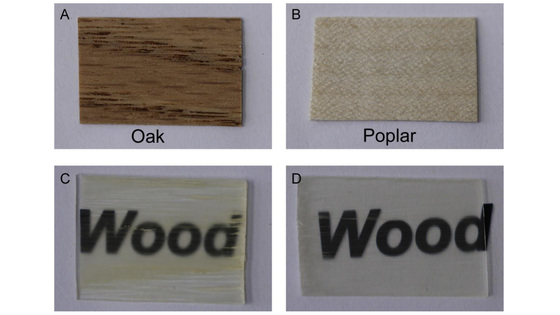

Wood is often used as a building material, but the strength of wood itself is inferior to that of cellulose. The reason is that wood is made up of 40-50% cellulose and the rest is made up of hemicellulose and lignin, which acts as a binder. Lee and his team have succeeded in devising a way to process wood to remove weaker components without destroying the cellulose that is the basis of the wood.

The processing method of hardened wood by Lee et al. Is mainly divided into two steps. The first step is to soak the wood in chemicals and heat it at 100 degrees to remove the lignin. Wood is a hard material, but when lignin is removed, it becomes soft and flexible and changes to a material like squeeze (low-resilience clay). It then performs a hot press to apply pressure and heat to remove moisture from the wood and densify it.

With this, the hardened wood is almost completed, but after processing it into an appropriate shape, it is possible to extend the life as a material by coating it with

Lee and his team are using a high-resolution microscope to examine the microstructure of hardened wood, revealing the secrets of its high hardness. According to Lee, 'The strength of the material is very sensitive to the size and density of cavities, grooves, holes, etc. In the wood by the two-step process we use when processing natural wood. There are almost no grooves to carry certain water or other nutrients, and defects (cavities, grooves, holes) in natural wood are greatly reduced or eliminated. ' By processing, he explained that he succeeded in making the hardness 23 times harder than usual.

Although more detailed analysis is still needed, the process of processing hardwood devised by the research team is expected to be more energy efficient and less environmentally friendly than other artificial material manufacturing methods. The research team hopes that hardwood will be used to create flooring floors that are resistant to scratches and abrasion in the future.

Related Posts:

in Science, Posted by logu_ii