Why on earth is a sharp and hard razor blade blunted by just shaving its beard?

Razors and knife blades are made of hard materials such as

How hair deforms steel | Science

https://science.sciencemag.org/content/369/6504/689

Why shaving dulls even the sharpest of razors

https://phys.org/news/2020-08-dulls-sharpest-razors.html

Human hair is a material that is 50 times softer than a razor blade, but nevertheless the razor blade becomes dull with continued use and must be replaced. ``Our aim is more or less everyone thinks,'Why razors and knife blades only interact with very soft materials,'' said

Tasan's laboratory is studying the microstructure of metals to design materials with excellent resistance to damage. 'We are metallurgists, and we want to learn about things that transform metals to make better metals. When we cut something very soft, like human hair, it's hard like steel The case where the material was damaged was very interesting,' said Tasan.

Therefore, a research team led by a graduate student Gianluca Roscioli belonging to Tasan's laboratory decided to carry out an experiment on the mechanism by which a razor blade becomes unusable when cutting a beard or hair. ..

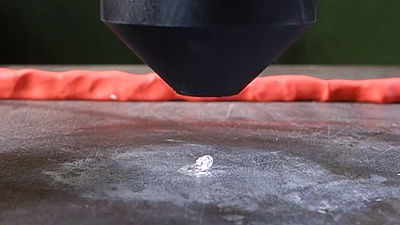

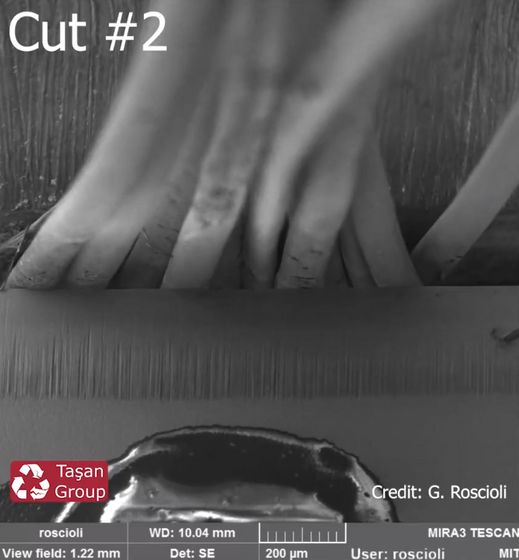

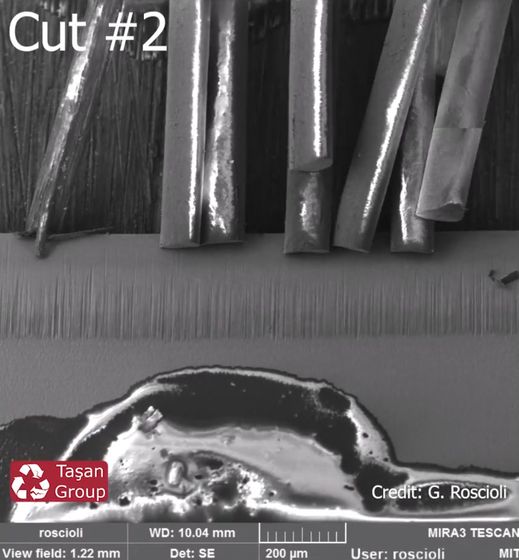

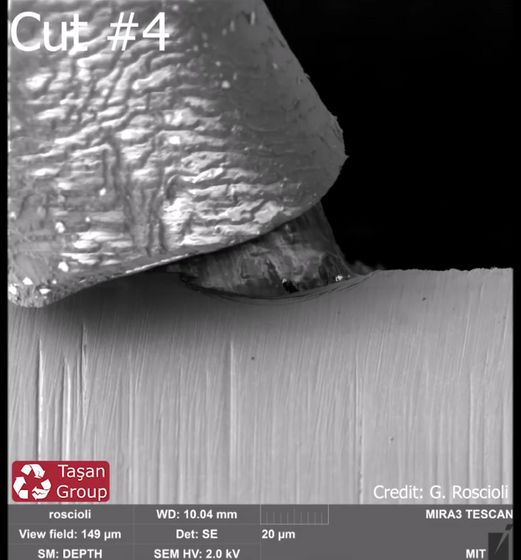

First, Roscioli repeated a preliminary experiment in which he used a disposable razor to shave himself and then shave the razor blade with a scanning electron microscope . As a result, it turned out that the razor blade is not sharp and the sharp part is not rounded, but a 'blade spill' in which a part of the blade is chipped occurs and the sharpness becomes dull. Therefore, the research team conducted an experiment to investigate the mechanism of blade spilling in a specific area just by shading.

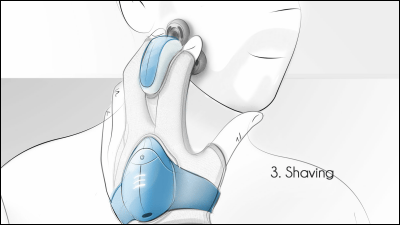

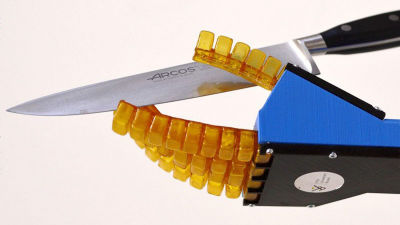

Roscioli said he created a device that mimics the situation of 'shaving beards and hair with a razor blade' in order to observe under more controlled conditions. This device was movable, and it was possible to adjust the blades of the razor fixed to the device and the tufts of hair at various angles, and to photograph the situation with a scanning electron microscope. The hair samples used were Roscioli's own hair and the hair given by a member of the laboratory, and he was able to use hair of various thicknesses in the experiment.

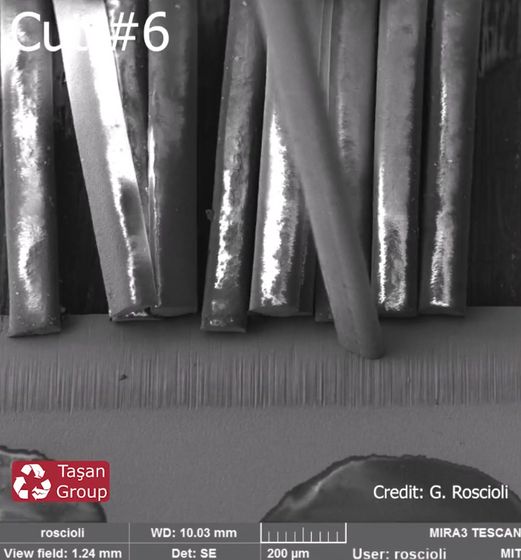

This is the image actually taken by Roscioli's research team. The razor blade approaches the hair...

I cut it quickly.

Repeat the experiment at different angles.

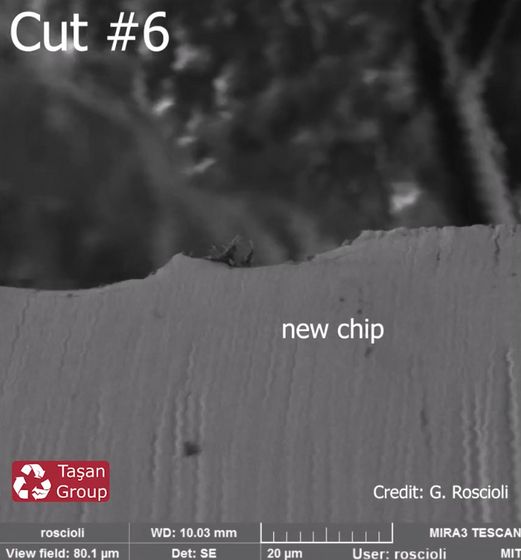

When I raised the magnification and focused on the cutting edge, there was a small spill on the razor blade.

After that, repeat the experiment several times...

In addition to the blade spill that was created earlier, a new blade spill has occurred.

It seems that the blade spill occurred regardless of the thickness of the cut hair, and it was not that 'the razor spills the blade because the hair is too thick and too hard'. Analysis of images and movies taken by Mr. Roscioli showed that when the hair and the razor blade were cut while being fixed in the vertical position, no blade spillage occurred, but the hair freely moved and the blade It has been found that blade spillage tends to occur when the angle of is changed.

To investigate more detailed conditions, the research team conducted a computer simulation to analyze under what conditions a razor that cuts hair is likely to spill the blade. As a result, the razor can be used when 'the blade and the hair approach diagonally', 'when the microstructure of the steel that makes up the blade is non-uniform', and 'when the fine spill that already exists on the blade contacts the hair'. It seems that he found that the blade easily spilled. In other words, it is a hint to make the blade last longer by processing the microstructure of the razor and knife blade more uniformly and cutting so that the blade is perpendicular to the one you want to cut as much as possible.

'Our simulation explains how non-uniformity of a material increases stress on the material, and cracks grow even when stressed by soft materials like hair,' said Tasan. Already, the research team has applied for a provisional patent that processes steel into a more uniform shape and creates a blade that lasts longer.

Related Posts:

in Science, Posted by log1h_ik