Succeeded in outputting a pseudo ventricle that beats like a real heart with a 3D printer and gel ink containing gelatin fibers

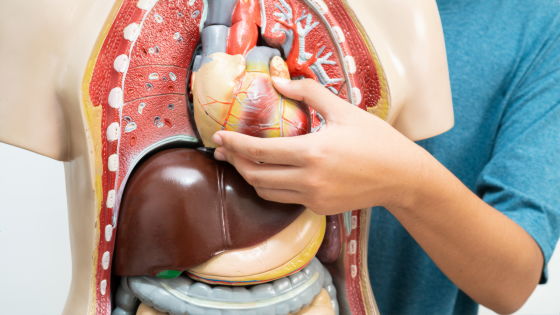

With the evolution of 3D printers, it has become possible to output biological tissue according to the data entered on the PC, and application of 3D printing technology to medical care is expected. Researchers at the John A. Paulson Graduate School of Engineering and Applied Sciences (SEAS) at Harvard University have announced that they have successfully 3D printed a pseudo ventricle that can reproduce the heartbeat using gelatin-infused

Fibre-infused gel scaffolds guide cardiomyocyte alignment in 3D-printed ventricles | Nature Materials

https://doi.org/10.1038/s41563-023-01611-3

Fiber-infused ink enables 3D-printed heart muscle to beat

https://seas.harvard.edu/news/2023/07/fiber-infused-ink-enables-3d-printed-heart-muscle-beat

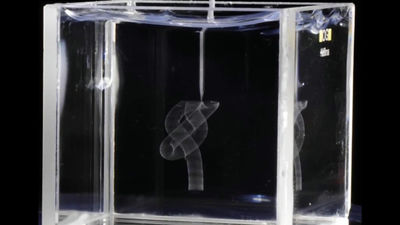

You can see how the actually output pseudo ventricle beats in the GIF animation by clicking the image below.

Gelatin has a strong image as an ingredient in sweets and dishes, but it is originally a kind of fibrous animal protein. This time, the SEAS research team used FIG (Fibre Infused Gel) ink, which is made by injecting this gelatin into a water-based hydrogel.

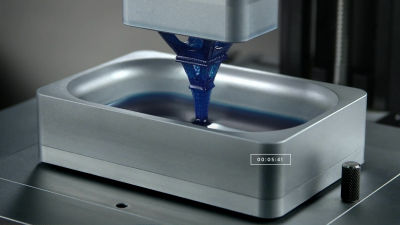

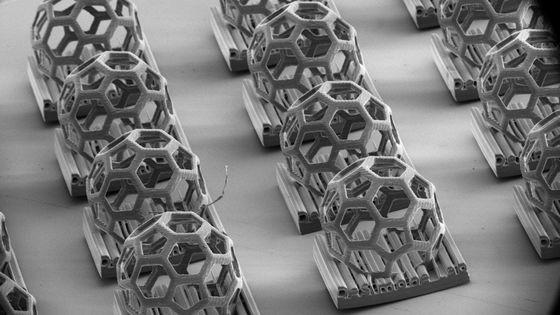

'The FIG ink has the property of maintaining its shape once the structure is printed, even though it flows through the 3D printer's nozzle,' said Suzy Choi, a SEAS researcher and lead author of the paper. Thanks to these properties, we have found that we can output simulated ventricle-like structures and other complex geometries without the use of supports or scaffolds.'

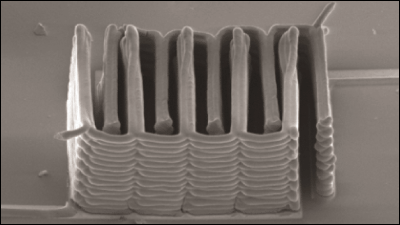

Mr. Choi and his colleagues used the `` rotary jet spinning technology '' devised by SEAS biophysicist Kit Parker to make FIG ink. This rotary jet spinning technology, inspired by cotton candy machines, uses centrifugal force to create ultra-fine fibers less than 1 micron in diameter. The gelatin fibers produced by this technique are sheets that look like cotton, and Choi's research team has further expanded the sheets of gelatin fibers into microfibers that are 80 to 100 micrometers long and 5 to 10 micrometers in diameter. It was decomposed by sound waves and mixed with hydrogel ink.

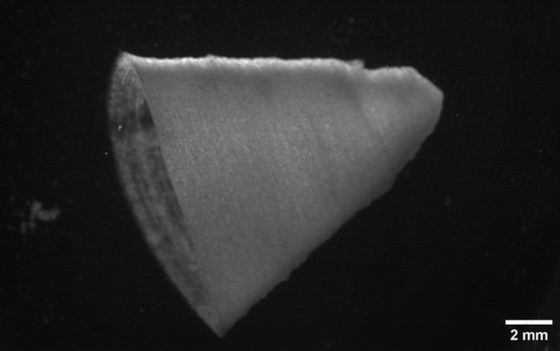

When printing a simulated ventricle with this FIG ink, by controlling the printing direction, we succeeded in aligning the simulated myocardial cells in a line along the fiber direction. When electrical stimulation was applied to the 3D printed structure as it was, it contracted along the direction of the fiber and started a pseudo pulsation. ``It was very exciting to see the simulated ventricle actually beating, just like the ventricle of a real heart is beating,'' Choi said.

Furthermore, by adjusting the direction of printing and the formulation of the ink, we found that the contraction of the pseudoventricle could be made more powerful. The improved pseudo ventricle can pump out 5 to 20 times more body fluid than the first output pseudo ventricle. The research team is working on building a more realistic heart tissue that can pump out liquid with strong pressure.

“FIG is just one of the tools we developed for the purpose of additive manufacturing,” Parker said. Instead, we don't rely on one tool, we're looking for better ways to build biology.'

Related Posts:

in Science, Posted by log1i_yk