What is innovative technology "continuous liquid interface 3D print" that enables 3D printing at the explosion speed?

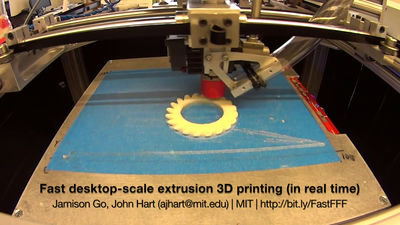

The place of activity of 3D printers continues to spread, not only to output small objects,Building a big apartmentOr,Chocolate with complex shapeMake,Sending data to the universe to create the necessary parts with the spacecraftIt is utilized in various forms. However, the big drawback of 3D printers is that "speed of outputting three-dimensional objects" is slow. Completely new technology to solve the weakness of this 3D printer and 3D printing at the explosion speed "Continuous liquid interface 3D printing"Is being studied.

Continuous liquid interface production of 3D objects

http://www.sciencemag.org/content/347/6228/1349

New nonstop 3D printing process takes only minutes instead of hours | Ars Technica

http://arstechnica.com/science/2015/03/new-nonstop-3d-printing-process-takes-only-minutes-instead-of-hours/

You can understand how "continuous liquid interface 3D print" outputs 3-dimensional objects and how much the explosion speed is in one movie by seeing the following movie.

Tumbleston2 - YouTube

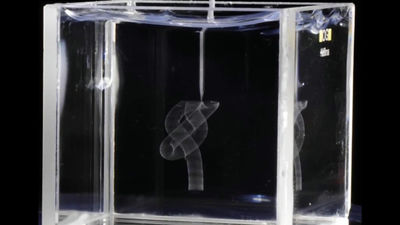

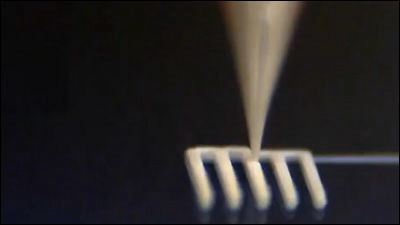

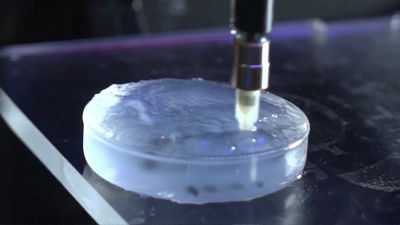

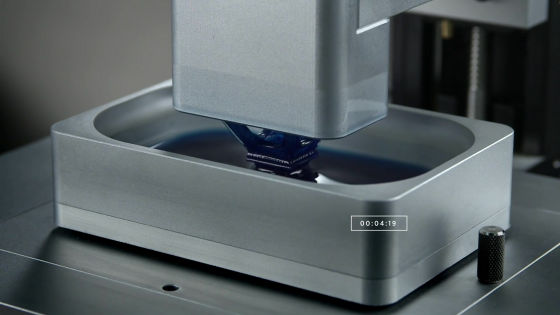

Liquid is contained in a metallic container.

Metal objects immersed in liquid started to slowly rise.

Three-dimensional objects can be seen between metal objects and liquids.

As the metal goes up, three-dimensional objects are generated at the interface, and you can see how the three-dimensional shape grows out shortly.

Three-dimensional objects gradually revealed their appearance.

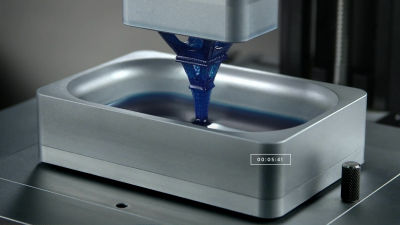

Apparently it seems 3D printing of the Eiffel Tower.

As the tip of the tower (lower part in the image) becomes thinner, the output speed increases.

Thus the output of the Eiffel Tower is upside down.

This movie was fast-forwarded by using a continuous liquid interface 3D printing technology to output three-dimensional objects of about 5 cm in only 6 minutes. In the continuous liquid interface 3D printing, it seems that three-dimensional objects can be output at a speed of 500 mm per hour,UV curable resinIt is the speed to overwhelm the existing bottom side irradiation type optical type 3D printer that uses.

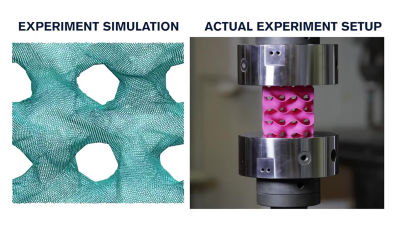

The continuous liquid interface 3D print was developed by the research team of John Tamburston of University of California and others, and the research results are scientific journalsPosted to Science as a paperIt is being done. In 3D printers using conventional UV curing type resin, there was a problem that the model and the modeling tank were fixed when the resin solidified. On the contrary, in continuous liquid interface 3D printing, the radical polymerization type UV-curable resin is difficult to cure at the interface with oxygen, which is a technique in which curing is prevented by oxygen between the liquid and the model The thin layer was formed and the adhesion was lost, so it became possible to output continuously, which means that we succeeded in raising the printing speed.

Related Posts: