A method of outputting parts of an artificial heart without collapsing by self weight with an inexpensive 3D printer of 100,000 yen class

Study to make artificial heart with 3D printerAlthough it is being advanced, there is a difficult problem that it is difficult for a small part of the heart's blood vessels etc. to be too soft to output. In order to solve this problem, researchers at Carnegie Mellon University are developing new technologies that will enable artificial hearts to be output even with cheap 3D printers.

Three-dimensional printing of complex biological structures by freeform reversible embedding of suspended hydrogels | Science Advances

http://advances.sciencemag.org/content/1/9/e1500758.full

How to 3-D print a heart | KurzweilAI

http://www.kurzweilai.net/how-to-3-d-print-a-heart

By watching the movie below you can understand how to print 3D artificial heart parts 3D while preventing how to break by their own weight.

Adam Feinberg Demonstrates 3-D Bioprinting Process - YouTube

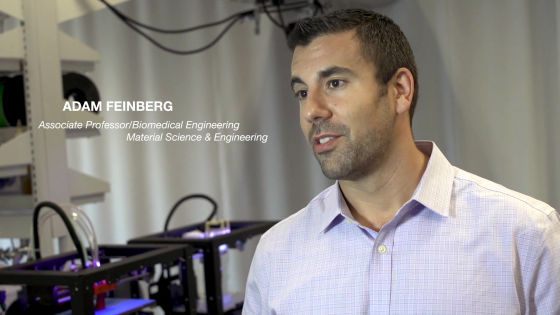

A research team of Professor Adam Feinberg of Carnegie Mellon University conducts research to output artificial heart with a 3D printer.

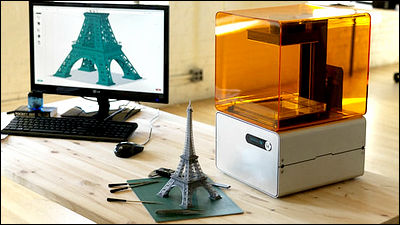

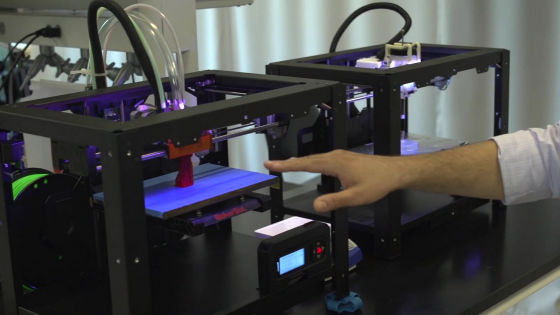

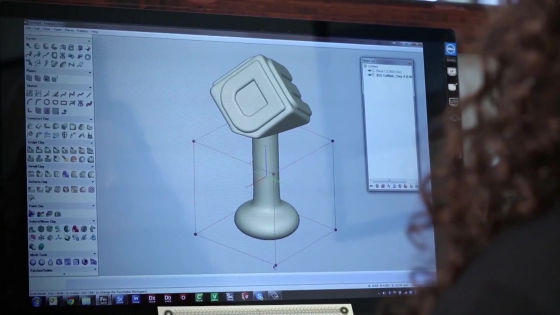

This is a 3D printer actually used in research. The 3D printer itself is a commercially available product, it is a very common product.

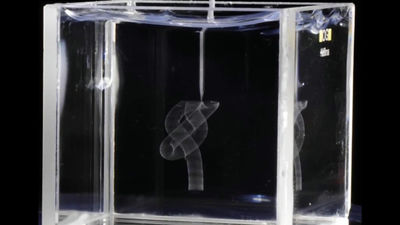

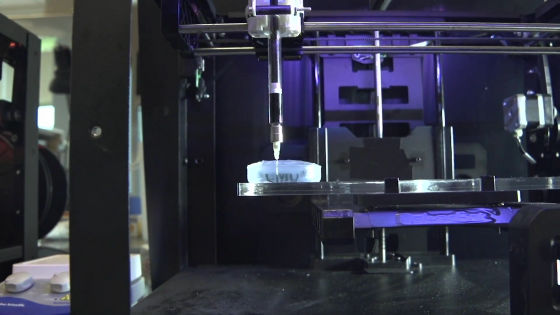

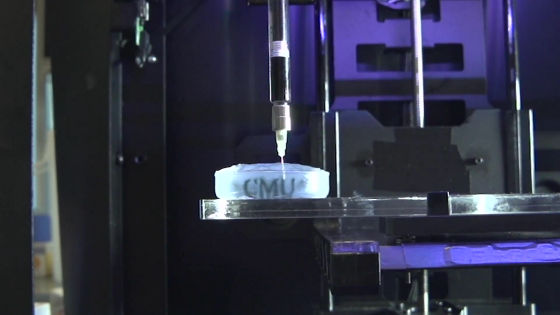

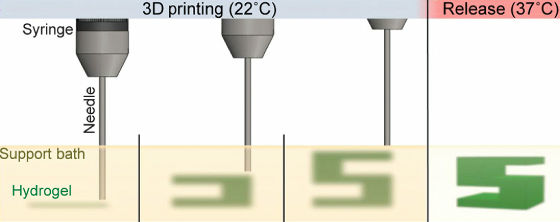

There is an essence of Dr. Feinberg's research results in the material and output method outputted in the form of the letter "CMU (Carnegie Mellon University)".

General 3D printers output solids.

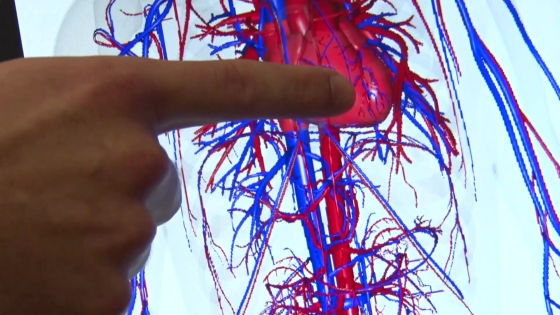

On the other hand, in order to output an artificial heart, it is necessary to output with a soft material derived from human cells so as to function in a living body. In order to make it function as an artificial heart, it is necessary to reproduce fine and soft parts such as blood vessels, but when trying to output them with a 3D printer, the difficulty that the organization can not be formed as intended because it collapses by its own weight It is said to occur.

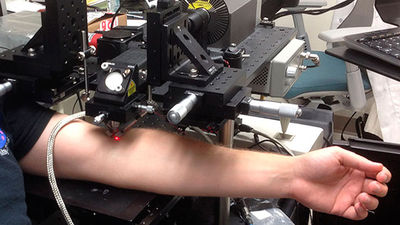

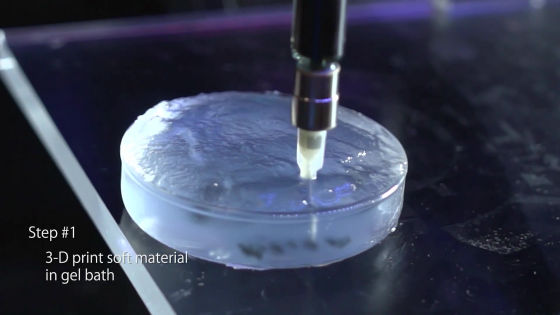

Therefore, this technology is developed to be able to 3D print to a precise shape even in a soft tissue. The point is in the environment to output.

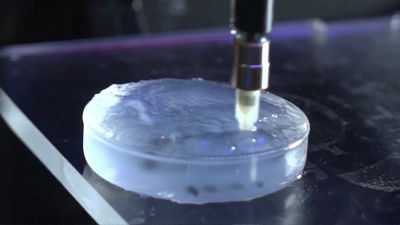

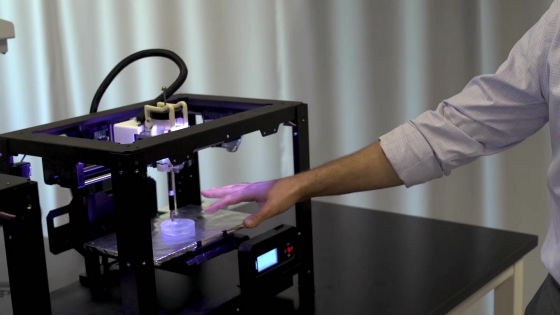

An idea that prevents collapsing parts output by supporting with a gel by self-weight by making gel-like gel tank in Petri dish and outputting part for artificial heart in it.

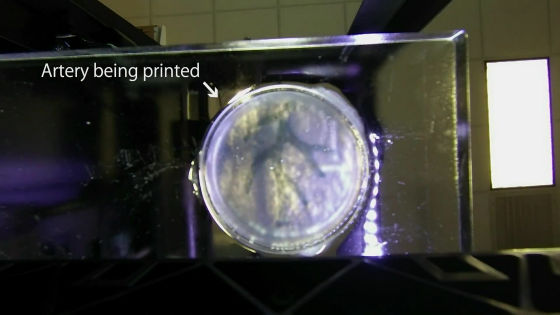

You can see that blood vessels are output in the gel tank with peeling like looking down from the bottom of the petri dish.

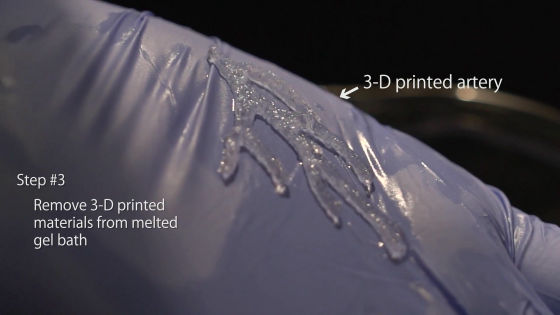

When the output is over, the Petri dishes are heated to the liquid of the beaker ......

I attach with a donbon.

Gel-like gel tank dissolves in high temperature liquid ......

Only the target part is left afterwards.

"Experiments using a gel tank to output a soft material for an artificial heart are done using a relatively inexpensive 3D printer that costs less than $ 1000 (about 120,000 yen)," Dr. Feinberg said.

In addition, it is said that software is developing as open source.

Dr. Feinberg says, "It is effective for optimizing parameters and it is possible to 3D print the organization that is required for artificial heart with the highest quality" about the reason why open source development is done.

The method developed by Dr. Feinberg is to print 3D tissue of the artificial heart while pushing the gel with the needle-like head pierced in a water-soluble gel that dissolves in a high temperature liquid.

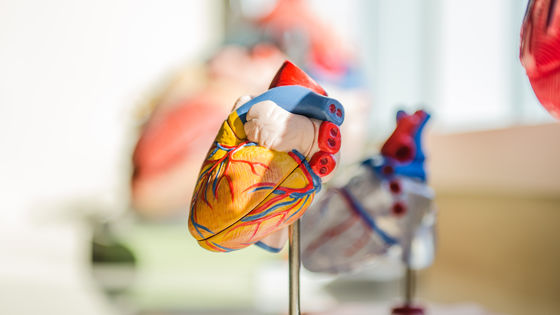

He already succeeded in 3D printing of the branch part of the coronary artery of the heart. Research that 3D printing of artificial heart seems to become full-scale.

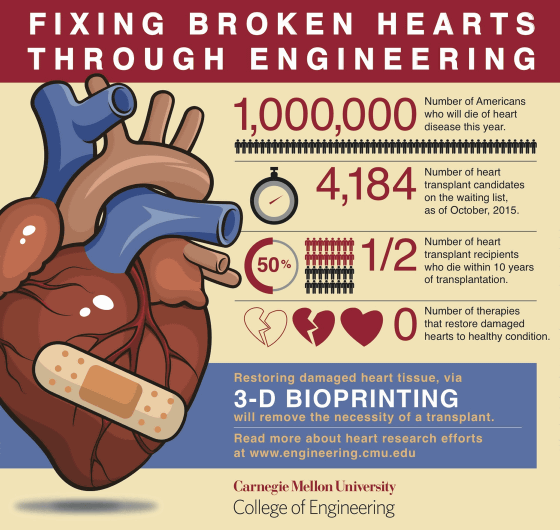

Patients waiting for heart transplantation are always 4,000 at any time in the US alone and the survival rate after 10 years of transplantation will remain at only 50%. It is expected that the lives of many cardiac patients will be saved if technology to 3D printing the heart using ingredients derived from their own cells is established.

Related Posts: