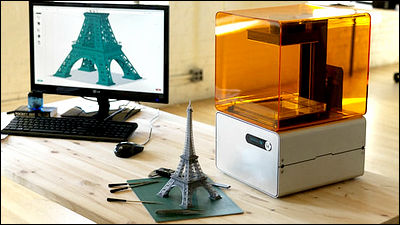

Inexpensive 3D printer "FORM 1" which can reproduce precisely even complicated structures

It is possible to finish with a very high quality similar to a 3D printer used by professional designers "The Form 1". Three-dimensional objects up to 125 x 125 x 165 mm make it possible to create with surprisingly precise, smooth surface even small ones.

Formlabs - High Resolution Desktop 3D Printer

http://formlabs.com/

FORM 1: An affordable, professional 3D printer by Formlabs - Kickstarter

The movie is from the following.

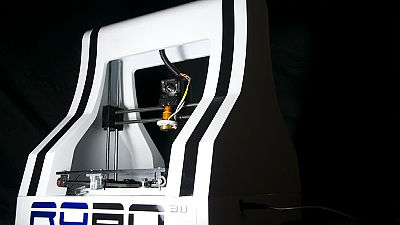

FORM 1 is a desktop 3D printer.

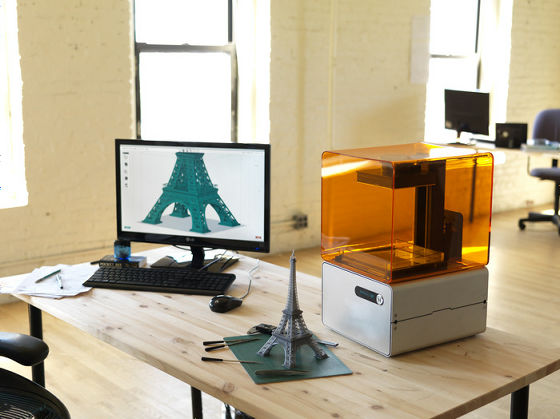

The body looks like this.

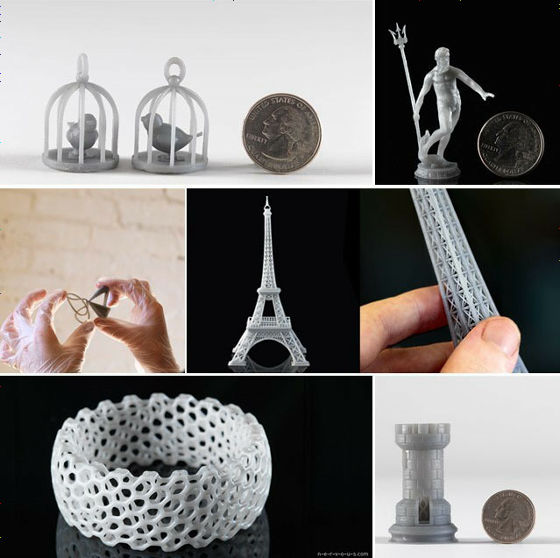

Even if it has a small and complicated structure, it can print quite precisely.

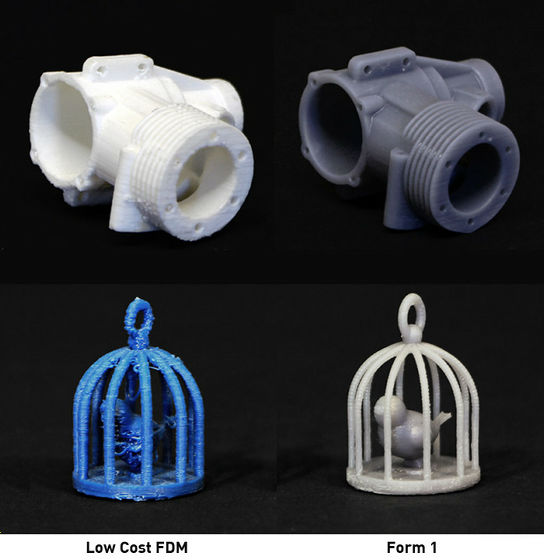

Though conventional 3D printers had problems with quality, such as the details becoming clumsy and smooth surface can not be drawn, but there are hundreds of 3D printers used by professional designers Sometimes I will do as much as ten thousand yen, so I could not get out of hand easily. So, let's make affordable 3D printers while maintaining professional quality! It is this "FORM 1" that was developed.

The left photo was made with an existing low price 3D printer, and the right side was printed with FORM 1. You can easily understand the difference in perfection just by glancing.

Those that print with FORM 1 are designed with dedicated software. In addition, this software is pretty simple specification, it has few setting tasks and it is designed to work on design right away.

The following 4 people made it. This is MAXIM, one of Co-Founder of Formlabs Company who developed FORM 1

DAVID

NATAN

And the founder JON.

If FORM 1 is up to 125 × 125 × 165 mm, it is possible to make very small, three-dimensional objects that are very precise up to the details.

SKYLAR, a special researcher at the Massachusetts Institute of Technology, designs geometric structures in architectural studies, but that FORM 1 is useful for actually confirming the design in three dimensions .

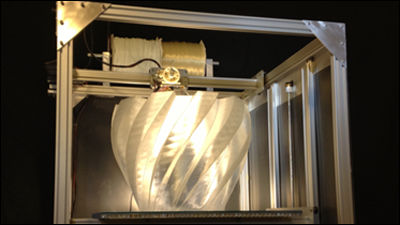

Complex structures are also this street.

The situation of actually using dedicated software is as follows.

After finishing the design, pressing the "SUPPORT" button ......

The supporting part that supports the three-dimensional object will appear on the screen at once.

The support part is like this when completed.

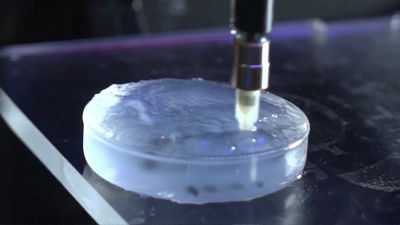

FORM 1 prints with laser using stereolithography (stereolithography).

Stereolithography is originally very expensive, but this time we succeeded in making printers of 200,000 yen range while using expensive lasers and optical instruments.

The liquid plastic cures by applying a laser.

When three-dimensional object is completed ......

Remove it from the printer.

Since the support part is attached under the main body, remove it and use it.

The printer comes with a kit for finishing.

It is completed by passing the finished product through water

Passing a blue liquid through butterflies with pipes inside ... ...

It flowed smoothly without clogging.

Currently completed materials are gray liquid plastic only

However, after the success of this project, we plan to increase color variations and make transparent materials.

In addition, while FORM 1 is currently recruiting equity for commercialization, it is $ 2299 (about 170,000 yen) for shipment to the US, $ 2999 for shipping to other countries (about 230,000 yen ) You can get with.

The deadline is Japan time on October 26 (Friday) 21:45.

Related Posts: