World's first carbon fiber output compatible 3D printer "Mark One"

Carbon fiber(Carbon fiber) is a "light and durable" material with a tenfold strength with a specific gravity of one quarter of iron, but the disadvantage is that processing is difficult and the manufacturing cost is high. A desktop-sized 3D printer which made it possible to output such carbon fiber for the first time in the world is "Mark One"is.

The world's first Carbon Fiber 3D Printer

https://markforged.com/

You can see how the world's first carbon fiber 3D printer "Mark One" prints carbon fibers from the following movie.

Meet the Mark One: the world's first Carbon Fiber 3D printer - YouTube

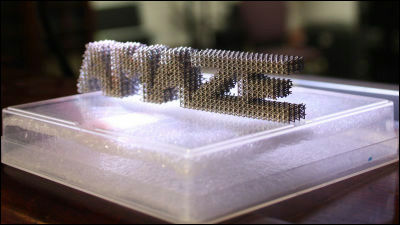

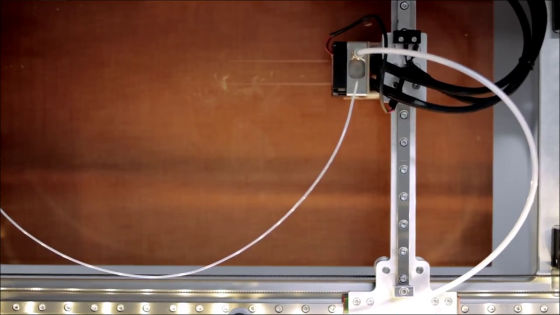

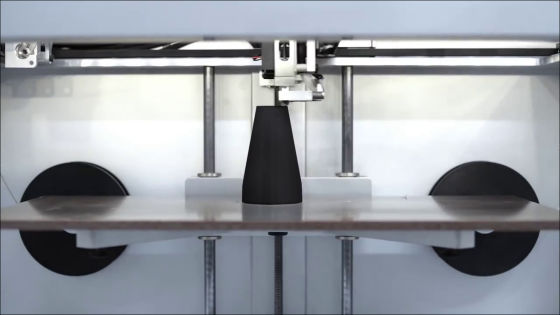

Printing starts inside Mark One.

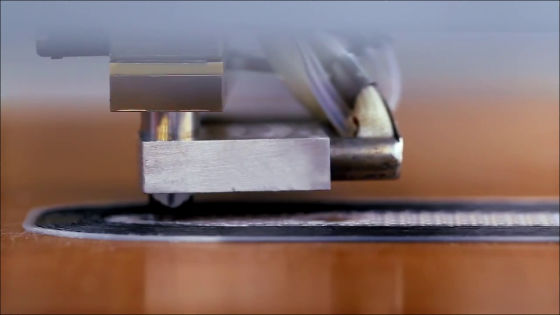

You can see that the filament of black carbon fiber is outputted flat from the head part.

Also, as the pedestal goes down ... ...

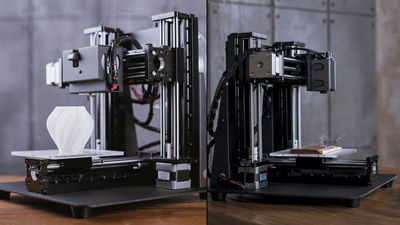

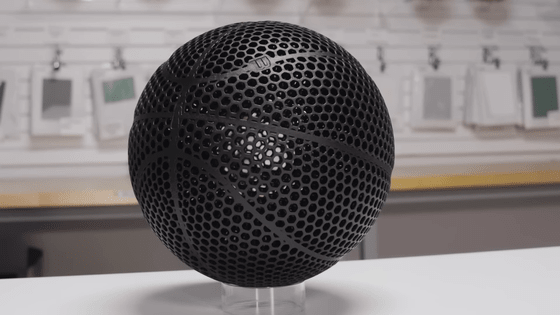

Three-dimensional objects by carbon fiber can also be printed in this way. Output method is conventionalFFFMethod of proprietary technologyCFF (Composite Filament Fabrication)It corresponds to the system, and the maximum output size is 305 mm × 160 mm × 160 mm.

You can produce parts using carbon fiber of lightweight and durable material at home.

Besides carbon fiberGlass fiber,Nylon,PLA,Kevlar fiberProcessing is possible.

Mr. Greg Mr., former aerospace engineer CEO, said he got the idea of carbon fiber 3D printer from his experiences involved in the design and manufacture of high-performance race cars.

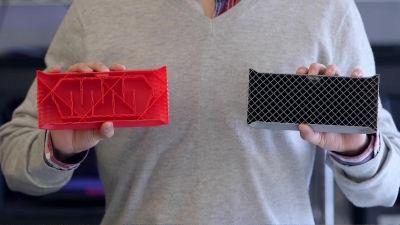

Below is the wing base of the race car made with Mark One. By combining three pieces of "carbon fiber + nylon base", "honeycomb nylon" and "CFF output carbon + nylon case" together, it is lightweight, durable and cost saving actual race specification It is possible to produce a wing base.

According to software settings, it is also possible to construct a honeycomb layer, which means cost and weight can be reduced.

The following is an example cost of material when 3D printing is done with Mark One. The light and durable wing parts with carbon fiber is $ 19.07 (about 1954 yen), making it with nylon alone is $ 8.91 (about 913 yen).

Looking at the cost of material that can be output with Mark One by every pound (1 pound = 453.592 g) / cubic inch / cubic centimeter,

Carbon fiber: $ 550 per pound (about 56,660 yen) / $ 25.34 per cubic inch (about 2600 yen) / $ 1.55 per cubic centimeter (about 158 yen)

Glass fiber: $ 199 per pound (about 20,000 yen) / $ 10.96 per cubic inch (about 1123 yen) / $ 0.67 per cubic centimeter (about 69 yen)

· Nylon: $ 99 / pound (about 10,000 yen) / $ 3.65 per cubic inch (about 374 yen) / $ 0.22 / cubic centimeter (about 22.5 yen)

· PLA: $ 22 per pound

It has become.

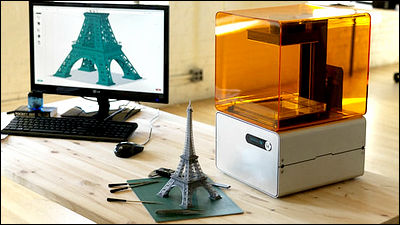

When you look up the carbon fiber printed with 7 mm × 3 mm × 100 mm, you can see that printing is possible with very fine detail.

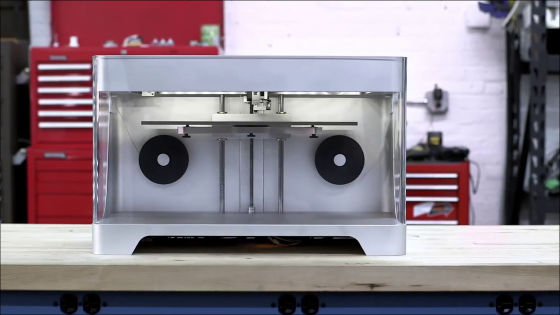

The dimensions of the main body are 360 mm × 575 mm × 322 mm.

Processing carbon fiber usually requires extensive equipment, but Mark One has a size that can be placed on the desktop cleanly.

In addition, Mark One is currently accepting pre-orders from the following pages. Mark One, which includes carbon fiber (100 cubic centimeters), glass fiber (150 cubic centimeters), nylon (1000 cubic centimeters), PLA (1000 cubic centimeters) as test filament, is priced at $ 4,999 (approx. 51,2300 yen) . The top version "Mark One Developer Kit" is $ 8799 (about 900,000 yen). In addition to being able to output Kevlar fiber, Developer Kit is a model that can simultaneously output two kinds of materials with premium support of soft with premium support, carbon fiber (200 cubic centimeters), glass fiber (300 cubic centimeter) as a test filament, , Nylon (2000 cubic centimeter), PLA (2000 cubic centimeter) are attached.

The world's first Carbon Fiber 3D Printer

http://markforged.com/#pre-order

Related Posts: