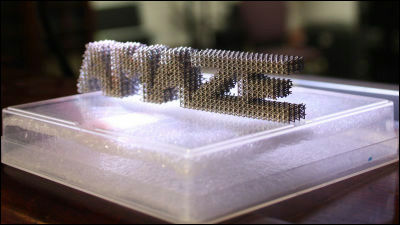

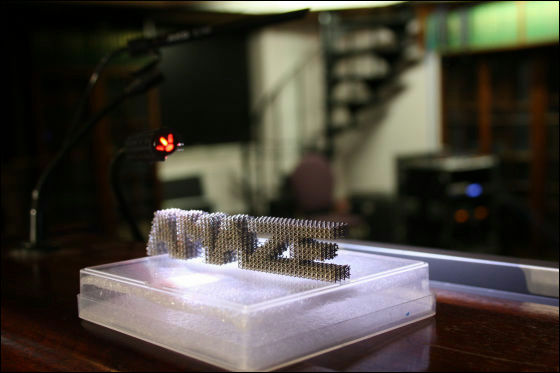

A revolutionary project "Amaze" that outputs metal at a level that can be used for parts of a spacecraft, a jet aircraft, and a nuclear fusion reactor with a 3D printer

The technology of 3D printing is progressing day by day,Output liquid metal with 3D printerTechnologies have also been announced, but on October 15European Space Agency(ESA), by outputting metal with a 3D printer, metal processing is possible without putting loss "AmazeThe project was announced.

Amazing future / Highlights / Human Spaceflight / Our Activities / ESA

http://www.esa.int/Our_Activities/Human_Spaceflight/Highlights/Amazing_future

BBC News - Amaze project aims to take 3D printing 'into metal age'

http://www.bbc.co.uk/news/science-environment-24528306

The Amaze project was established with the aim of forming spacecraft / jet machines and parts of a fusion reactor with 3D printers, and within 5 years it will realize practical level metal printing out. For this project,Airbus,Astrium,Norsk Titanium,Cranfield University,EADS,CCFE(Column Science Center Nuclear Fusion Research Division), and 28 organizations from various fields and industries.

In addition, in France, Germany, Italy, Norway and the UK, the preparation of factories of metal 3D printers has begun,Supply chainThe development of it is also proceeding.

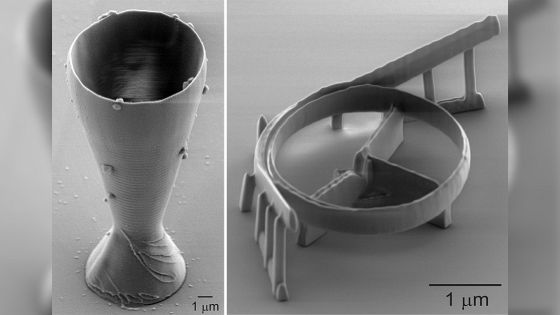

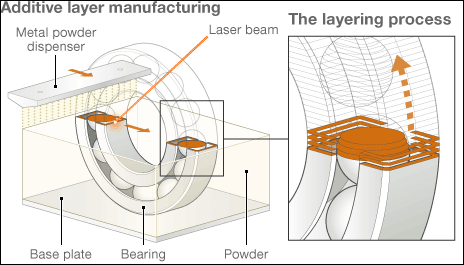

As a mechanism of a 3D printer that outputs metal, the design software determines the shape of the 3D model from the cross section, while stacking the metal powder, heat it to solidify while etching the cross section with the laser.

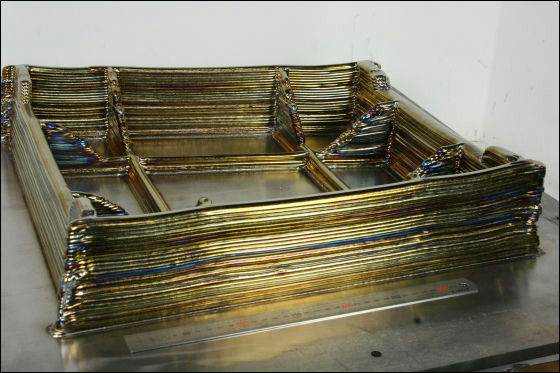

Normally, many losses are generated in the processing of metals, and often precious metals are wasted, but by printing metal with a 3D printer, the loss in processing becomes almost zero, 1 kg of metal We can produce 1 kg of metal parts. titanium·tantalum·vanadiumWe can also obtain great merit of being able to process raw materials such as expensive metals like waste without waste.

AmazeLondon Science Museumso,tungstenAnnounced an object printed alloy, it is a tungsten alloy that can withstand 3000 degrees of high heat, there is a prospect that it is possible to print parts that can remain in the fusion reactor or nozzles of the rocket which will become extremely hot, and furthermore It is said that the printing of metal parts of jet engines exceeding 2 meters and wings have already been successful.

David Jarvis, head of ESA's New Materials and Energy Research Division, said, "Our ultimate goal is to make artificial satellites consisting of a single part that need not be tightened by bolts" If completed, the cost of several million euros necessary to make a satellite can be reduced to 50%.

However, Mr. Jarvis also told that "At this stage, the porosity becomes high, there is a problem that a lot of small bubbles are formed on the surface," and to solve this problem, space development, nuclear fusion · It is said that collaboration among industries such as aviation technology becomes important.

Related Posts: