Research is under way to make a real heart within 10 years with 3D printers

ByMandalina

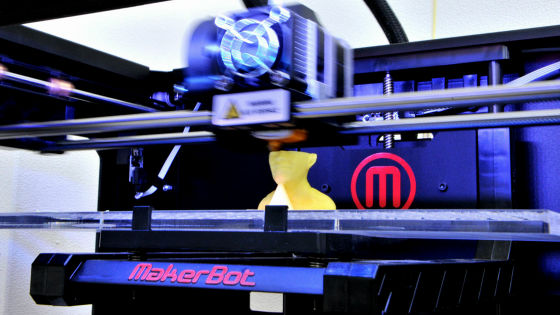

3D printing technology not only creates objects such as figures,As a means to solve food problemsIt was devised,House constructionIn addition,A tissue that functions similar to living tissueAlthough it is made, research to make a real heart is newly carried out, it is said that it will be possible to complete the heart using 3D printer in the next 10 years · It becomes possible to transplant an organ.

Lab-Made Heart Represents 'Moonshot' for 3D Printing | LiveScience

http://www.livescience.com/41280-3d-printing-heart.html

Louisville Researcher, Stuart Williams, Ph.D., is Closing in on Printing 3-D Hearts «Cardiovascular Innovation Institute (CII) Cardiovascular Innovation Institute (CII)

http://cv2i.org/louisville-researcher-stuart-williams-ph-d-is-closing-in-on-printing-3-d-hearts/

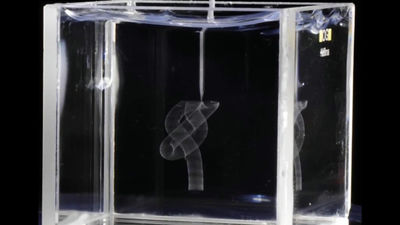

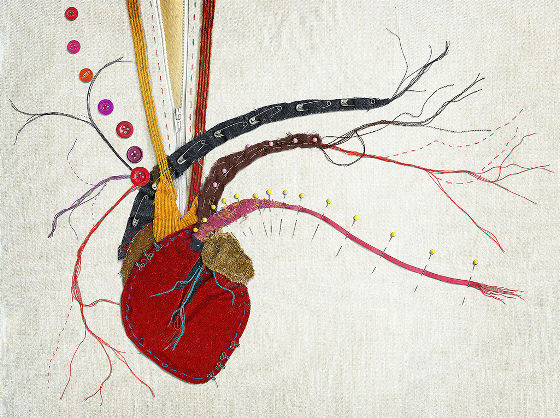

The idea of making a heart using a 3D printer isCardiovascular innovation research institute (CCI)Thanks to Stuart Williams. The laboratory has already undertaken the development of this next-generation 3D printer, and it is possible to make a perfect heart composed of myocardium, blood vessel, heart valve etc. when the printer is completed. "Individual components of the heart can already be printed out, but we are making the next generation 3D printer that will make up the heart from the beginning," Williams said.

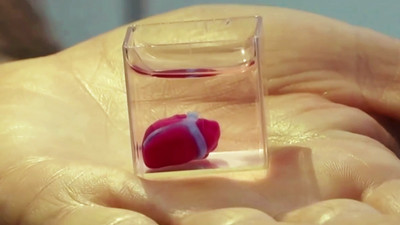

3D researchers who create organs with 3D printers in the field of regenerative medicine are one of the big goals for the heart. Techniques for making small chunks of liver and kidney in tissues where cells are stacked like a layer using a 3D printer have already been established and in many cases stem cells collected from bone marrow and fat are used. Williams' artificial heart uses stem cells taken from fat as well as this technique.

The laboratory led by Williams starts with making each part with a 3D printer, and by combining these parts it is going to make a fully functioning heart in one week. When making a bio heart, Mr. William says to a colleague, "How about assembling the heart like a big plane?", The best way is to organize and organize the organs into separate components I have concluded.

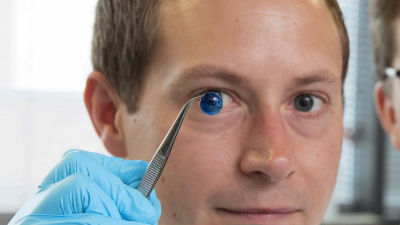

The most difficult problem in making this heart is creating a blood vessel. In order to make organs function, it is necessary to make a very complicated reticulated blood vessel when creating a standard size organ. Although it would be ideal if it would be possible to create fine blood vessels with 3D printing technology, the current 3D printer can output at least a few millimeters of structures, while blood vessels become finer, it will be as fine as a few microns It is. Because 1 millimeter is 1000 microns, this difference can be said to be quite large. Therefore, Williams et al. Have cells rather than 3D printsSelf-organizationIt is planned to create organs by creating reticulated blood vessels using ultrafiltration and connecting them to the organs that were finally output by 3D printers. William explains, "Make a few tens of microns or hundreds of microns with a 3D printer and develop cells by self-organization."

ByMichael Novelo

Many researchers do not believe 3D standard printed organs will be realized in the next 10 to 15 years, but CII is pursuing research on artificial heart with the goal of completion in 10 years. According to Ms. William, this "bio printer" is scheduled to start from December.

Related Posts:

in Science, Posted by darkhorse_log