The Netherlands Navy is proceeding with a project to 3D scan all the vessels it holds

Organization responsible for the management of vessels of the Navy "Marinebedrijf Koninklijke Marine"Is proceeding with a project to create digital data by 3D scanning of vessels owned by the Navy. With this technology, it seems that it is also possible to exchange "damaged" parts on site during the operational actions.

Scanning the Dutch navy - Naval Technology

http://www.naval-technology.com/features/featurescanning-the-dutch-navy-5920931/

The Royal Netherlands Navy is 3D scanning all their ships - The Verge

https://www.theverge.com/2017/10/1/16387528/royal-netherlands-navy-dutch-3d-scan-ships-artec

The purpose of moving forward with this project is to digitize all of the shape data of the ship, thereby greatly increasing the speed of maintenance and repair work. Parts used for ships are not necessarily all created from the drawing, but there are cases where only the actual actual item exists. By preparing three-dimensional shape data using such a 3D scanner, we prepare to prepare on-demand immediately when parts become necessary due to aging or breakage This is the ultimate goal of this project.

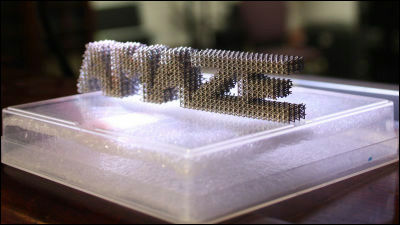

The project uses a hand scanner made by Artec 3DArtec EvaWhenSpace SpiderAnd that. Scanning the shape with a scanner that uses LED as the light source instead of laser light and importing it into the PC creates the "surface" that composes the part and creates the 3D data that can actually make the part.

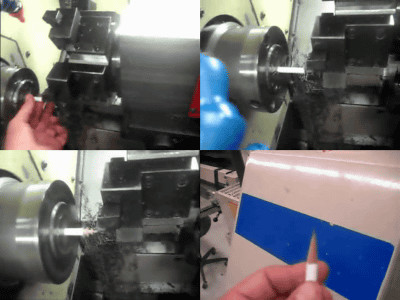

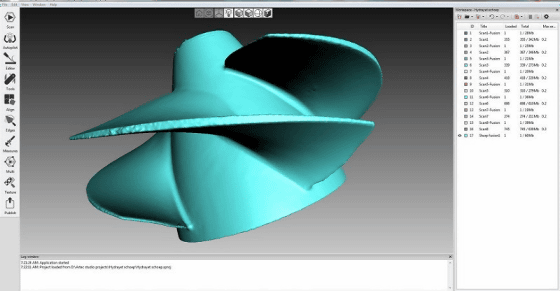

Marinebedrijf Ben Jensen of Koninklijke Marine says, "By introducing 3D scanning, we can shorten weeks of work. In older ways, using a number of measuring instruments and converting drawings to CAD data Nevertheless, there is no 3D data and parts can not be made by machine.Artec's handy scanner allows you to convert parts from reality to 3D datareverse engineeringcan. From that data it will be possible to create parts using 5-axis machining machine tools and 3D printers. "

For Artec 3D, this project is a model that demonstrates the concept of utilizing 3D technology of military use of the company. At the company, future warships have a 3D scanner and a 3D printer installed, and we have a vision of "repairing parts" on site at repair in case of breakage or breakdown. Andrey Bakrenko, executive officer who oversees product development at Artec 3D said, "Since there are errors even in vessels made with the same design, the final error will be several meters in size if it becomes a huge ship There is only a way to measure with the 3D scanner how to accurately grasp the actual size, "he says the merit of the technique using the 3D scanner.

The time it takes to actually scan all Navy vessels is still unobservable. In addition, it is said that detailed verification is required for the degree of strength and durability of 3D printed parts. However, as aircraft makers such as Boeing and Airbus are making products using 3D printers, introduction of such technologies will be further advanced even for military applications that require further performance and reliability .

A wonderful machine to "output" jet engines for aircraft in the world's largest 3D printer was born - GIGAZINE

Related Posts: