MIT creates a self-propelled 3D printer robot, assembles the building in 14 hours, and in future it will also operate in space

Materials that can be output with 3D printers are increasing year by year, and at the beginning only plastic materials were now available for metal and glass, and even food. Meanwhile, researchers at the Massachusetts Institute of Technology (MIT) have created self-propelled 3D printers that can output the building body to further evolve 3D printers.

3-D printing offers new approach to making buildings | MIT News

http://news.mit.edu/2017/3-d-printing-buildings-0426

Autonomous robot 3D printers like this could help build homes for us on other planets - The Verge

https://www.theverge.com/2017/4/27/15447578/autonomous-robot-3d-printers-mit-homes-planets

MIT's newly created 3D "Digital Construction Platform (DCP)" is not something to use on the desk, it is automatically moved to the construction site with the robot arm and caterpillar mounted, and it starts working as it is It is a robot that can do. The following movie was filmed to show its usefulness, outputting domed walls in just over 13 hours.

System can 3-D print an entire building - YouTube

MIT's DCP started designing for the ideal construction robot. DCP is required to use substances found at the construction site and to clean the environment that is covered with ice and dust, and DCP will be able to automatically output buildings even if there are no people to operate Is the target. In other words, we will be able to output buildings using this 3D printer even at remote locations like Mars, which has limited resources, but it is the goal of MIT.

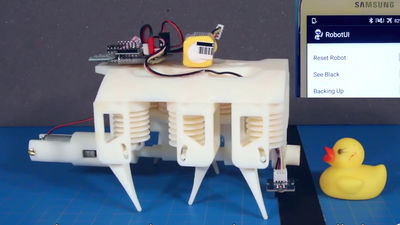

It looks like this when actually outputting.

Because it is equipped with a caterpillar ......

It is self-propelled. Although it was planned to install a diesel engine when first designed, solar panels and battery packs are adopted in prototype machines. The weight of the prototype is 8100 pounds (about 3700 kg), and the production cost is about 250,000 dollars (about 28 million yen).

Extend the huge hydraulic robotic arm and draw a circle.

At the tip of the robot arm is a small arm capable of fine work, attaching an attachment for output to make a building.

The dome-shaped building produced by DCP in the movie is 12 feet tall (about 3.7 meters high) and 50 feet (about 15 meters) in diameter. If it is a real construction plan, "The Verge wrote the overseas news," You should have put concrete in the dome produced by DCP. "

After outputting, the DCP went out of the gap left vacant.

Various attachments can be attached to the tip of DCP's robot arm. By installing foam insulation guns and welding equipment, thermoplastic extruder for spraying molten plastic, shovels etc., it is possible to do various work with one DCP.

Although MIT's 3D printer is at the stage of proof of concept, it was published in Science Robotics, a science magazine related to robot technologypaperAccording to the company, it is possible to reduce the cost of construction work by automatic construction using a 3D printer, and it is also aiming at raising the safety of workers. In addition, MIT says that this self-propelled 3D printer will also be useful for missions on the moon and Mars, and if humans migrate to planets other than the Earth in the future, they may live in buildings built by DCP I do not.

Speaking of creating buildings with 3D printers, GIGAZINE has covered "Contour Crafting", which uses a huge 3D printer to output the entire house and cases in Russia. However, it is expected that the more versatile 3D printer type robot, which is different from either, will be MIT's DCP, and what kind of evolution will be going on in the future.

"Contour Crafting" to build a house with a huge 3D printer in 20 hours - GIGAZINE

Related Posts: