Succeeded in building an entire house in frigid Russia in just 24 hours using a 3D printer

Attempts to output buildings with 3D printers are being made all over the world, but Russia's construction 3D printer development company '

The first on-site house has been printed in Russia | Apis Cor. We print buildings

http://apis-cor.com/en/about/news/first-house

The following movie explains Apis Cor's unique 3D printer that can output the entire building as it is at the construction site.

Apis Cor: first residential house has been printed! --YouTube

A yellow building built in the frigid region of Russia where snow is piled up.

This is a concrete house built in just one day using a 3D printer.

Attempts have been made to build buildings using 3D printers.

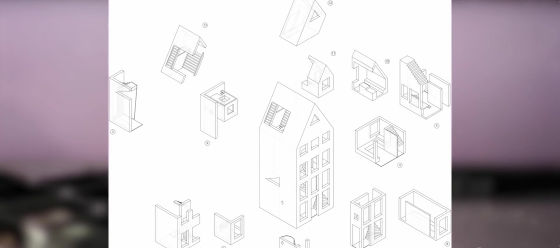

However, in most cases, a method was adopted in which a part of the house was printed out and assembled.

Also, it is common to use a huge 3D printer installed indoors to make a part of a prefabricated house ...

The output 'box' had to be transported to the site and reassembled.

However, Apis Cor's 3D print house has the great advantage of not requiring assembly because it is printed out locally.

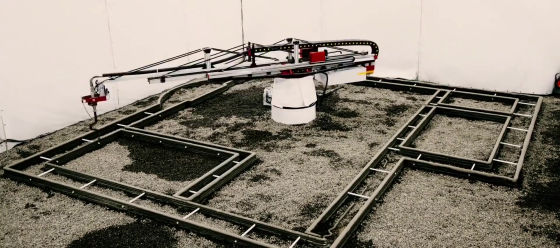

A special 3D printer developed by Apis Cor made it possible to print in 3D at the building site.

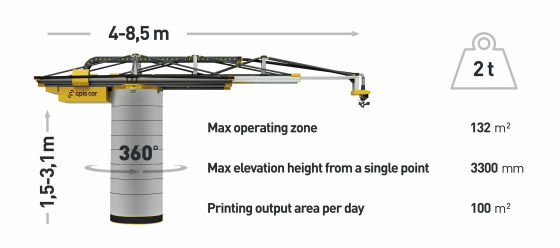

The design is such that the print head that outputs building materials rotates.

Apis Cor's 3D printer has an arm length of 4 meters and a height of 1.5 meters. It weighs 2 tons and is extremely compact. The legs and arms can be expanded and contracted as needed, the printer itself can be extended up to 3.1 meters in height, the arms can be extended up to 8.5 meters in length, and 'print' buildings up to 3.3 meters in height. It is possible.

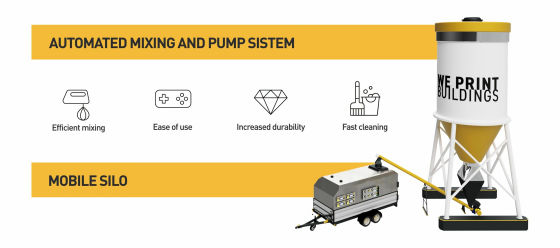

In addition, a mixer that mixes concrete for construction is built in the cylinder. Although it is a compact machine, it can output up to 100 square meters of buildings per day.

Apis Cor is building a building. Since the arm rotates, it is easy to output curved walls, which is difficult in ordinary houses.

Compact 3D printers can be transported by truck.

You can assemble it in just one hour and start building work.

Apis Cor's 3D printer can output the entire building locally, so the work of creating the skeleton is completely automated without the need for human labor.

Compared to the conventional manufacturing method that requires teamwork of construction workers, the speed and construction period are faster, and there are great advantages in terms of cost.

Of course, there is no problem with strength.

The Apis Cor experiment, which builds a house in just one day, was conducted in Moscow, Russia, which is covered with snow.

The temperature is minus 35 degrees.

Since the limit of output of concrete material is 5 degrees, it was solved by using a tent.

According to Apis Cor, once the composite resin material currently under development is completed, it is expected that 3D printing of houses will be possible at any time of the year, whether in winter or summer.

Stucco is used for the exterior walls and interior, making it easy to paint. Mineral plaster also functions as a heat insulating material.

The interior material made by KOROED has high adhesion and breathability, and is ideal for finishing work.

Although it has a flat roof, it has sufficient snow resistance.

Since it is flat, it can be processed into sheets, and by covering the roof covered with LOGICROOF polymer, durability can be maintained.

A heat insulating plate based on rigid polystyrene is stretched on the wall surface, and the gaps are also filled with rock wool powder.

In addition, by covering with polyurethane foam insulation, high heat insulation and airtightness are realized.

Double-glazed windows made by Fabrika Okon.

The indoor environment is the same as that of a general concrete house.

The building built by Apis Cor in the test is a one-story building with a floor area of 38 square meters.

The construction cost is as low as $ 10,134 (about 1.15 million yen).

The unit price per square meter is 275 dollars (about 31,000 yen)

This construction cost includes all the basic parts of the building such as foundation, roof, interior / exterior finish, walls, windows, floors, and ceiling, and the unit price per square meter is compared to the general box-shaped house made by the existing construction method. It is cheap at 223 dollars (about 25,000 yen), and it is said that the construction cost can be suppressed by 45%.

In addition, because of the three-dimensional structure unique to 3D printers, the amount of materials can be reduced by 70% compared to general construction methods, so it can be said to be economy and ecology.

Apis Cor's 3D print house can dramatically shorten the construction period by automatically creating the basic frame of the building in just one day. If it is put into practical use, it will be very effective not only for general housing but also for construction of temporary housing in disaster areas.

Related Posts: