Using a 3D printer so that a hut can be made with a material cost of 100,000 yen

Attempts to utilize 3D printers in construction have been ongoing for over five years. Under such circumstances, Italian 3D printing company WASP succeeded in making a hut with a crane-based 3D printer using concrete and mud as a material with only 100,000 yen units.

This Company 3D-Printed a House Made of Earth and Rice Husks | Digital Trends

https://www.digitaltrends.com/cool-tech/wasp-3d-printing-earth-material/

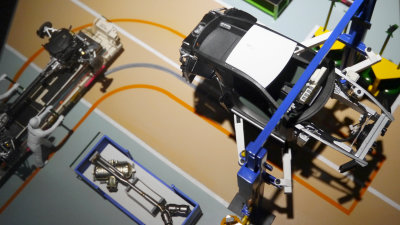

The image of the process of actually making a hut with a 3D printer "Crane WASP" has been released.

3D printing earth house with Crane WASP | work in progress - YouTube

A man attracting sand in the place to make a hut. The figure of Crane WASP making a hut behind is reflected.

Mix the sand with water to make it mud, and make it into the material of the hut together with the concrete.

Crane WASP will shape the shape of the hut in order from near the ground.

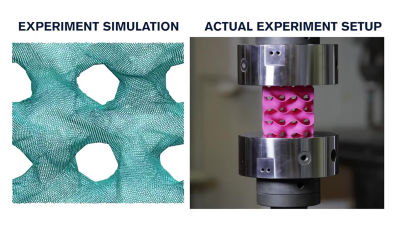

The wall which is shaping is hollow in the inside, and I will also insert millet and rice straw here. These natural fibers are said to play a role of minimizing the shrinkage of the mixture of concrete and mud when it dries and playing the role of giving strength to layered walls.

Construction takes about 10 days at 215 square feet (about 20 square meters). Material cost is about 1000 dollars (about 112,000 yen), and at the time of commercial deployment a little more expenses will be added, but considering that the latest iPhone XS Max (64GB model) is tax-free 124,800 yen , You can see that it is very cheap and easy to make.

Related Posts: