Is the United States depriving Taiwan of the world's largest semiconductor foundry TSMC?

by Lee Jilin

In recent years, TSMC, which has the largest share of the industry in Taiwan's semiconductor manufacturing company (foundry), is showing movements to set up fabs outside of Taiwan, such as Arizona in the United States and Kumamoto Prefecture in Japan. TSMC, which is advancing into the United States in the form of a conflict between China and the United States, is sometimes said to be 'stolen by the United States' in Taiwan. Regarding this issue, the owner of the YouTube channel Asianometry , which deals with Asian business and economy, has been asked several times by a Taiwanese friend, ``What do you think about TSMC?'' The following movie about this issue is explained.

Is America Stealing TSMC?-YouTube

In January 2020, it was reported that the US government was pressuring TSMC to manufacture chips in the US.

The US government demands domestic production for the world's largest semiconductor manufacturing foundry, is it due to conflict with China - GIGAZINE

And in May 2020, it was reported that TSMC would build a semiconductor factory (fab) in the United States. The fab that TSMC will build in Arizona was said to be equipped with N5 equipment, a 5nm manufacturing process.

Will the world's largest semiconductor manufacturing foundry 'TSMC' in charge of Apple's chip manufacturing build a factory in the United States - GIGAZINE

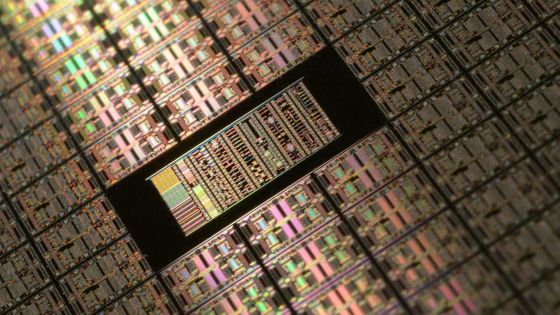

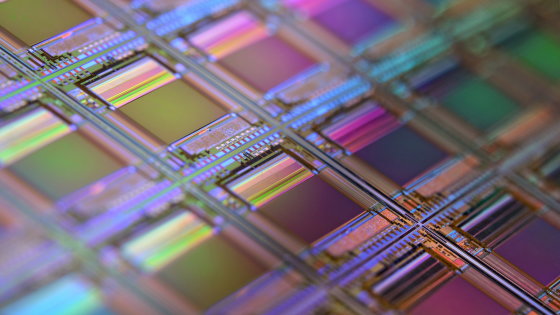

At that time, this news was not taken so seriously in Taiwan. It seems that the four huge fabs in Taiwan were able to produce more than 100,000 wafers per month, but the Arizona fab is small and can only produce about 20,000 300 mm wafers per month. Because it was supposed to be. There were also predictions that by 2024, when the fab would be completed and operational, the N5 itself would not be the most advanced process.

However, in December 2022, TSMC announced plans to introduce N4, an enhanced version of N5, and N3, a 3nm process, at a fab under construction in Arizona. In addition, it has also clarified that it is proceeding with a plan to build a second factory in Arizona.

TSMC's Arizona new factory will switch to 4 nm process instead of 5 nm in response to requests from Apple etc. - GIGAZINE

In addition, TSMC has announced that it will receive a subsidy of about 400 billion yen from the Japanese government to build a new fab in Kumamoto Prefecture, and has entered final coordination to build a fab in Germany as well. Announced in December.

TSMC Founder and Chairman Morris Chan has repeatedly said that 'the secret to business success is doing everything in Taiwan.' Asianometry says that the move to have fabs in Arizona and Kumamoto Prefecture is a departure from the norms that TSMC has followed for many years, and it is understandable that Taiwanese people are nervous.

Asianometry says that “demand and financing” are at the heart of this overseas expansion movement. TSMC is a company that communicates closely with its customers, most notably Apple, which accounts for about a quarter of its total revenue. Apple is not just a customer, it is also a sponsor that provides funds for TSMC to produce state-of-the-art chips, and without a partnership with Apple, TSMC could not continue to be the world's number one foundry. There is also

Without partnership with Apple, TSMC could not become the world's top foundry - GIGAZINE

Bloomberg, an American economic newspaper, reported that Apple is requesting TSMC to produce Apple's semiconductors at its Arizona factory. Since Apple holds a quarter of TSMC's revenue, it is believed that TSMC will listen to Apple's request.

TSMC announced a plan to build a 3 nm semiconductor factory in Arizona, and Apple's CEO Tim Cook stated that `` Apple silicon will be manufactured in Arizona ''-GIGAZINE

In August 2022, the U.S. Senate passed the `` CHIPS Act (Semiconductor Subsidy Bill) ,'' which provides more than $50 billion (about 6.7 trillion yen) in five years for fab construction in the United States. Passed. As a result, it can be said that TSMC has accelerated the flow of building a new fab in the United States. Already, semiconductor manufacturing is becoming a political issue rather than a technology or economic issue.

Pointed out that semiconductor manufacturing is no longer a ``political issue'' beyond technology and economy-GIGAZINE

And Asianometry denies that the US is stealing technology from TSMC. When conducting technology transfer , there are many things that local companies cannot do on their own, such as the need to produce semiconductors domestically, the acquisition of technology and knowledge, and the securing of fab equipment. . However, TSMC has wholly owned almost all of its fabs, including its facilities in China, with the exception of the fab in Singapore.

TSMC plans to spend about $ 28 billion (about 3.75 trillion yen) in 3 years with the investment by the fab under construction in Arizona, so about $ 9 billion (about 1.2 trillion yen) will be spent in one year. It is thought that there is TSMC has announced that it plans to make capital investment of about 36 billion dollars (about 4.8 trillion yen) in 2022, so about 25 to 30% of the one-year capital investment will be a fab in Arizona. It will be poured into.

And TSMC shipped about 14.2 million 300mm equivalent wafers in 2021. In 2022, we will be producing about 15 to 16 million pieces, that is, about 1.3 million pieces per month. Asianometry estimates that 75-85% of them will be made in Taiwan. Even if the Arizona fab is completed, it will produce about 20,000 wafers per month. Even if the production is expanded to 50,000 pieces per month, the production volume is about 0.3% of the total, and the production volume is not enough to meet the investment.

On the other hand, in Taiwan, construction of a fab that introduces cutting-edge processes such as N2 and N1 under development has been announced. There are also plans to build a new N28 process fab in Taiwan, Asianometry says, ``The opinion that the United States is stealing TSMC from Taiwan is a little ridiculous.''

by Lee Jilin

Also, since fab management, research and development, operation, supply chain management, etc. are all done in Taiwan, the possibility of losing everything to the United States is extremely low. In addition, Taiwanese companies such as ASE and SPIL hold a share of the process of assembling and packaging the produced wafers into semiconductors. Asianometry believes it will be difficult to do.

Related Posts: