It is reported that the global market is too dependent on 'TSMC', which is responsible for manufacturing chips of Apple and AMD.

Most of the chips in products such as Apple and AMD are manufactured by Taiwanese semiconductor foundry TSMC. The Wall Streat Journal, an American letter, reports that 'the world is too dependent on chip manufacturing to pose a risk.'

The World Relies on One Chip Maker in Taiwan, Leaving Everyone Vulnerable --WSJ

https://www.wsj.com/articles/the-world-relies-on-one-chip-maker-in-taiwan-leaving-everyone-vulnerable-11624075400

The world's reliance on TSMC could be disastrous --PhoneArena

https://www.phonearena.com/news/worlds-reliance-on-tsmc-could-be-bad_id132963

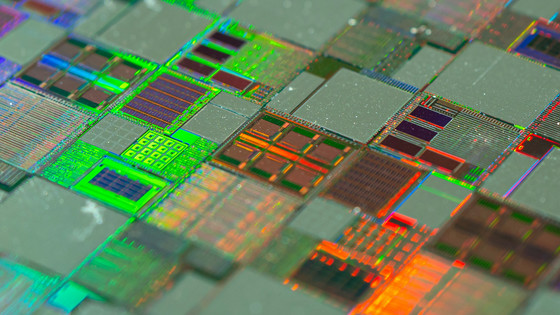

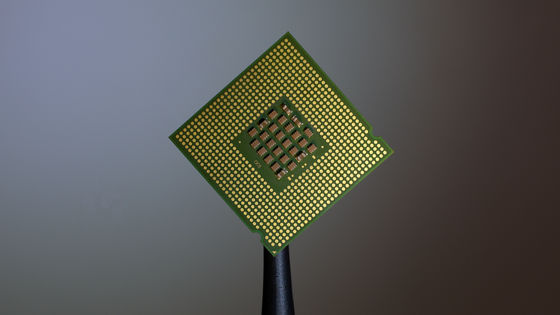

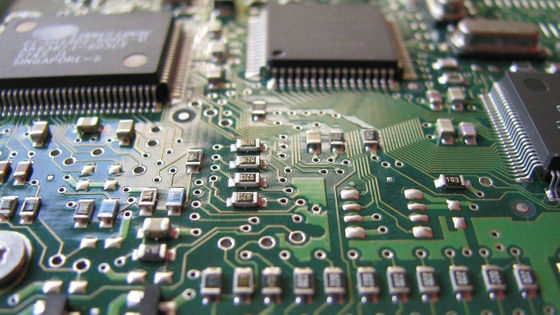

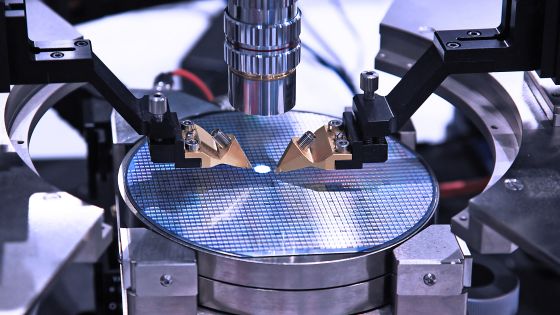

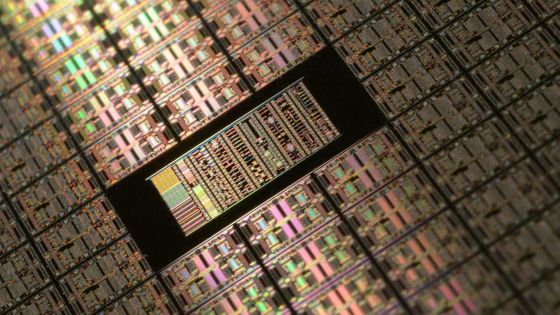

TSMC is the sole manufacturer of chips designed by all manufacturers in the world, including Apple, AMD, Qualcomm, and MediaTek. It is said that it is not so popular because it is not a company directly related to consumers, but its market capitalization is about 550 billion dollars (about 61 trillion yen), and it is said to be ranked 11th in the world market capitalization ranking. A huge company. According to market research companies, about 92% of the world's high-precision processors and 60% of in-vehicle processors are made by TSMC. In the world's top 10 semiconductor manufacturing revenue comparisons in the first quarter of 2021, TSMC accounted for 55% of total revenue, which is truly a “strongest” situation.

The Wall Streat Journal reported on this TSMC that 'dependence on TSMC poses a threat to the global economy.' As mentioned above, IT companies around the world rely on TSMC, and by taking advantage of this overwhelming advantage, TSMC is expanding its capital investment and further pushing out other companies in the same industry. According to market research firm IC Insights, other countries will need '30 billion dollars a year (about 3.3 trillion yen) x 5 years' to catch up with TSMC and Samsung. It is reported that TSMC will start mass production of next-generation 5nm process & 3nm process in 2022, and is about to start development of 2nm process, and is ahead of the industry in technology.

TSMC's next-generation 5nm process & 3nm process is scheduled to start mass production in 2022, and 2nm process is also under research and development --GIGAZINE

However, the fact that TSMC-based Taiwan is suffering from the worst drought in the last 50 years raises great concern. According to media reports, TSMC uses as much as 156,000 tons of water per day to clean dozens of metal layers that make up semiconductors, and is directly hit by water shortages due to drought. As a result of increased demand for semiconductors due to the pandemic of the new coronavirus that occurred in 2020, 'TSMC dependence' is being viewed as a problem under the circumstances where it is reported that 'semiconductor shortage has entered a dangerous area'.

Experts say that the shortage of semiconductors has entered the 'dangerous area', the waiting time for chips is the longest ever --GIGAZINE

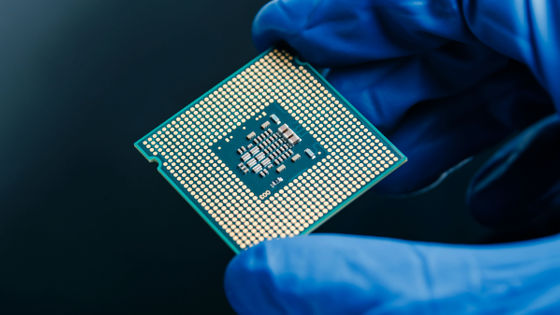

The Biden administration has announced that it will make a huge investment of 5.7 trillion yen in the domestic semiconductor industry in the bill to strengthen its competitiveness with China announced in June 2021, and is trying to break through TSMC's strongest state. .. In response to this situation, TSMC itself is trying to build a new semiconductor factory in Arizona. Not only is the U.S. continuing to put pressure on Chinese companies such as Huawei, but the U.S. authorities have determined that the possibility of conflict has increased due to the increase in Chinese military action in the suburbs of Taiwan. It is said that this is also a factor.

World's Largest Semiconductor Foundry 'TSMC' Starts Construction of Arizona Factory --GIGAZINE

In addition, C · C · Way CEO of TSMC for the worldwide semiconductor shortage 'at least 2022 year will not be eliminated chip shortage, finally likely to be eliminated out in 2023' shows the view .

Related Posts:

in Hardware, Posted by darkhorse_log