A cooking method is developed to output raw chicken with a 3D printer and bake it with a laser.

In recent years, research has been conducted on the use of 3D printers as cooking utensils, such as

Precision cooking for printed foods via multiwavelength lasers | npj Science of Food

http://dx.doi.org/10.1038/s41538-021-00107-1

Engineers figured out how to cook 3D-printed chicken with lasers | Ars Technica

https://arstechnica.com/science/2021/09/engineers-figured-out-how-to-cook-3d-printed-chicken-with-lasers/

You can see how to output chicken with a 3D printer and how to bake it by watching the following movie.

Robots that Cook: precision cooking with multiwavelength lasers --YouTube

Until now, techniques such as ovens and open flames have been used to bake meat.

This time, the research team worked on a method of baking meat using a laser and cooking it to the inside.

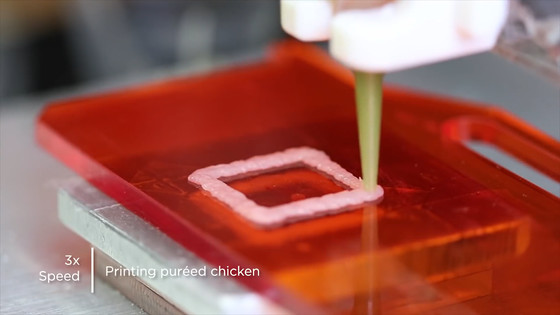

First of all, the chicken output by the 3D printer is ...

Grind in a food processor until pasty.

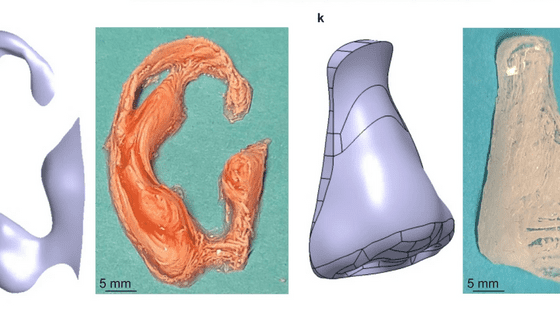

Then, the pasty chicken is accurately output in 1 mm increments with a 3D printer. Mold. However, with the current molding technology, it is extremely difficult to output chicken in three dimensions, so this time it will be molded in the form of thin chips.

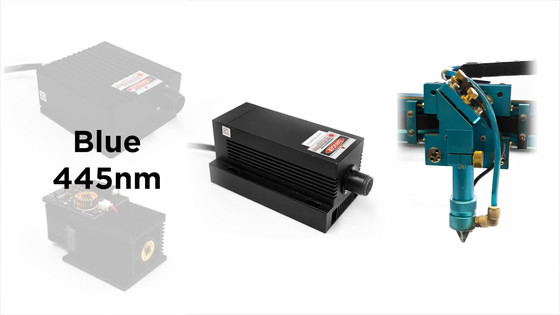

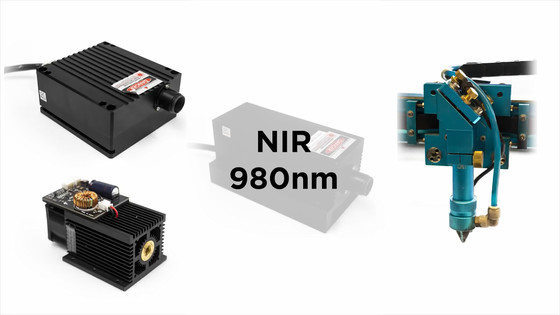

Three types of lasers were used in this study. One is a blue laser with a wavelength of 445 nm.

And a near infrared (NIR) laser with a wavelength of 980 nm

Finally, there is a mid-infrared (MIR) laser with a wavelength of 10.6 μm.

The laser runs accurately over the chicken, stacking circles over and over again. The research team sought a pattern for efficiently grilling chicken while adjusting the diameter and number of circles.

The merit of the method of 'baking with a laser' instead of an open flame or an oven is that the heating pattern can be set in detail. For example, it is possible to create a heating pattern with a complicated pattern as shown below.

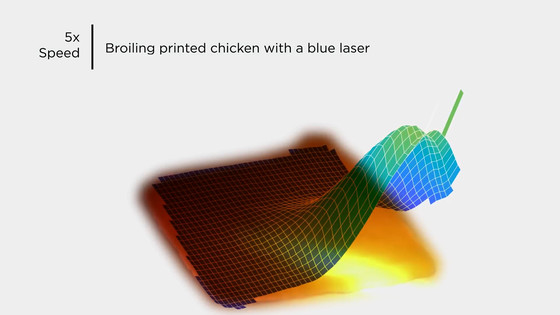

Below is a CG model that monitors the surface temperature of chicken when exposed to a blue laser. Unlike ovens and open flames, where the whole is heated, laser heating is local, so the way the fire passes depends on the output energy and frequency of the laser and the speed at which the laser is moved. Especially in the case of chicken, it is necessary to heat it to about 70 ° C or higher in order to sterilize parasites and bacteria that cause food poisoning, so the condition of the fire is very important.

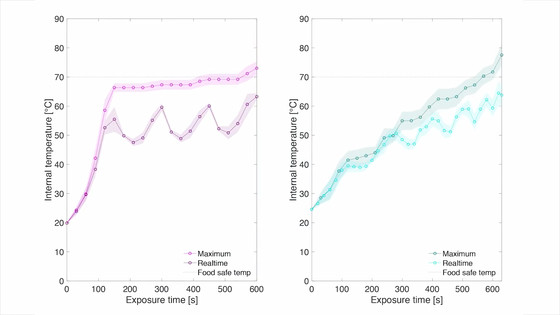

The graph below summarizes the total laser irradiation time (horizontal axis) and the internal temperature of chicken (vertical axis). 'Maximum' is the maximum internal temperature, and 'Realtime' is the internal temperature measured in real time. The graph on the left shows the case where one heating pattern is repeated four times, and the graph on the right shows the case where one heating pattern is run only once and baked slowly. Comparing the 'Real time' in the graphs on the left and right, the inside is burned more slowly and efficiently when it is run only once.

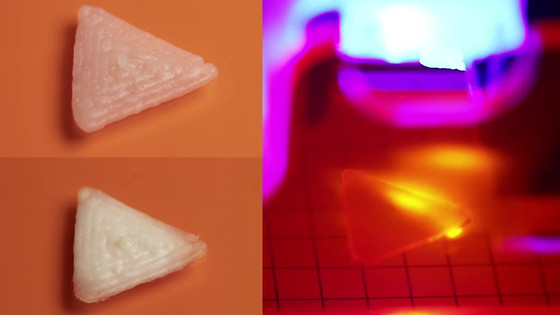

If the internal temperature rises quickly, it will lead to evaporation of water and affect the texture of the meat. This is chicken before roasting.

And the chicken after baking looks like this. Moisture is removed by baking, so the body shrinks and the weight becomes lighter.

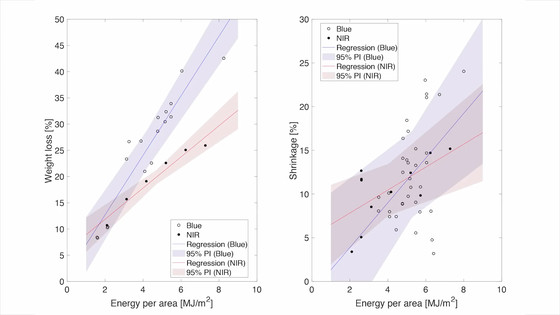

When comparing the baking with the blue laser and the NIR laser, it was found that the blue laser tends to lose more weight and volume of chicken. In other words, the NIR laser can be cooked while leaving more water, so it will be baked more juicy.

In addition, the laser passes through a transparent package, so you can bake meat in the package.

After the meat is cooked, it is finally grilled with a MIR laser. The blue laser has the characteristic that heat penetrates more into the inside, while the MIR laser is suitable for burning the surface of meat. By properly using lasers with multiple frequencies, it is possible to cook chicken so that the surface is properly cooked while thoroughly heating it to the inside.

The cross section of the chicken actually baked with a laser looks like this.

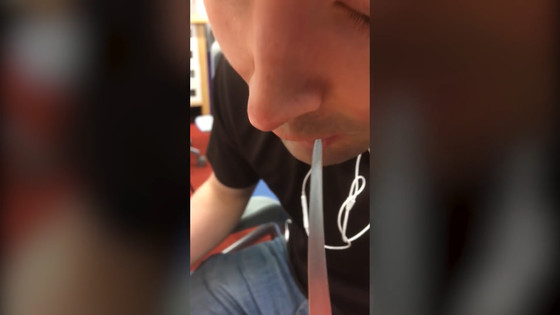

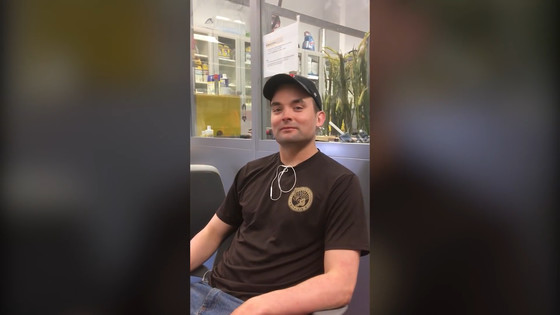

The research team ate a bite with Pakuri ...

I smiled with a smile. In the experiment, two testers tasted and evaluated that 'laser-baked chicken has a better texture and is juicy,' while 'the dentist uses a laser to fill the teeth.' There were also impressions that 'it smells like when irradiated' and 'the taste is slightly metallic'.

The research team says that the content of this research is just basic and not at a level that can be applied immediately. But in the future, he says, it could put cooking under full digital control and change the way we think about food.

Related Posts: