It is pointed out that the shortage of chips is not the only bottleneck in the shortage of semiconductors.

The world is suffering from semiconductor shortages, as

The Chip Shortage Has Made a Star of This Little-Known Component --WSJ

https://www.wsj.com/articles/a-big-hurdle-to-fixing-the-chip-shortage-substrates-11630771200

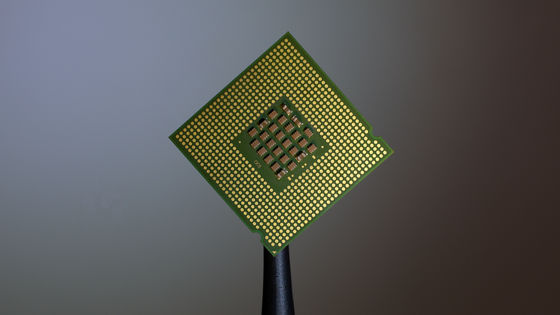

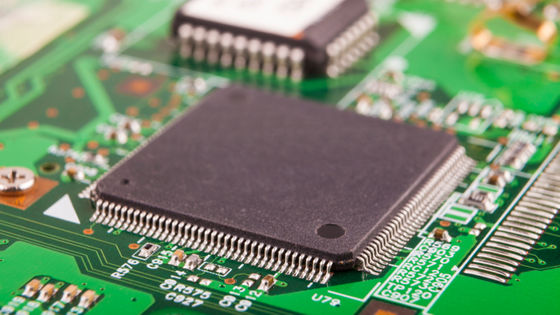

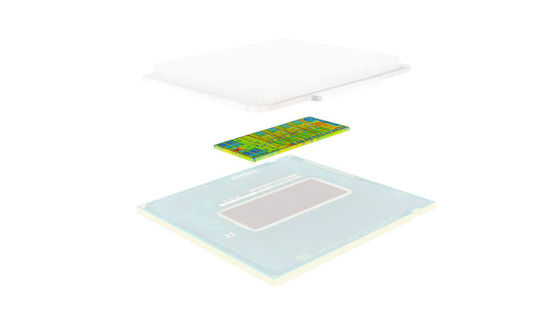

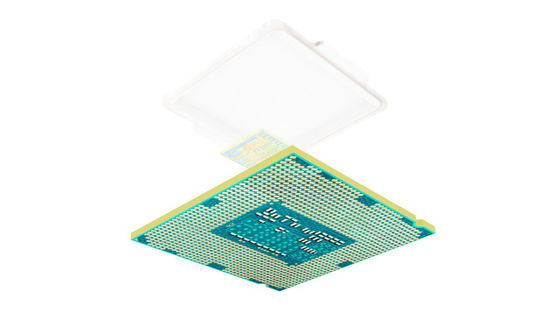

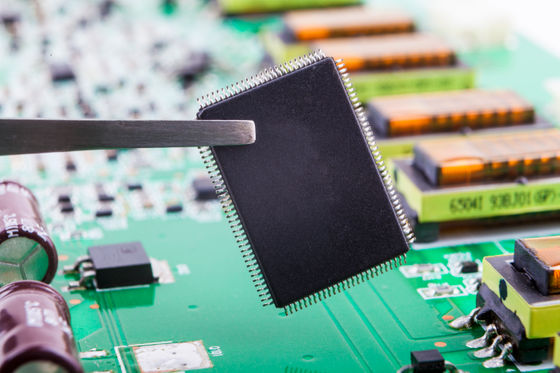

The semiconductor has a three-layer structure consisting of a resin that protects the core chip, a chip '

The Wall Street Journal points out that the major bottleneck in semiconductor shortages is the underlying packaging substrate.

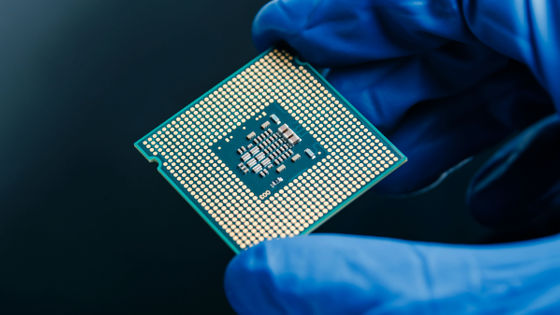

The extra-fine wiring coming out of the chip cannot withstand a direct connection to the printed circuit board, so a package board must be sandwiched between them. Although package substrates play an important role in semiconductor manufacturing, The Wall Street Journal states, 'Semiconductor manufacturers spend most of their manufacturing costs on chip parts that directly affect performance, and package substrates have been outsourced. Has been putting pressure on the companies that manufacture packaged substrates to keep prices low for many years. '

According to The Wall Street Journal, 'Companies that manufacture packaged substrates have also tended to reduce production based on past experience.' Former Intel's Tadashi Kamewada said, 'Package board manufacturers expanded their scale in 2010, when the PC market was expected to expand, but when the market contracted from 2012 to 2018, each company said that it was in excess inventory. I was troubled by various expenses. '

However, the demand for packaged substrates has suddenly increased in recent years when the shortage of semiconductors has become a hot topic. In response to this rapid increase in demand, a board maker in southern China said, 'We have entered an era that we could never have imagined that a business could be established just by manufacturing a board.' 'This is the semiconductor manufacturing industry. 'We will accept much higher prices than before,' experts say, 'the supply shortage of packaged boards will continue for several years.'

In response to this situation, semiconductor manufacturers are shifting toward 'manufacturing package substrates in-house.' AMD and Intel have announced plans to invest in board manufacturing, and NVIDIA has announced plans to purchase the entire production line, including package board manufacturing.

Package substrate manufacturers are also taking action in response to the shortage. IBIDEN, which is based in Gifu Prefecture, announced that it will invest 180 billion yen in a factory in Ogaki City to start operations in 2023 in order to increase the production capacity of packaged substrates. In addition, Taiwan-based AT & S has announced that it will spend $ 2 billion to build a plant in Malaysia, and is planning to start production in 2024.

Semiconductor manufacturing companies are forecasting an increase in demand in the future, and package substrate manufacturing companies are also expected to increase profits in the future. 'Some companies have raised prices and slightly increased their profits,' said Jean Baldaman of consulting firm TechSearch International. 'The supply and demand for advanced packaging boards needed for powerful chips will continue to grow. '.

Related Posts:

in Posted by log1p_kr