Experts say that the shortage of semiconductors has entered the 'dangerous area', the waiting time for chips is the longest ever

Bloomberg reported on May 19, 2021 that the waiting time for delivery of semiconductor chips as of April reached 17 weeks. It is feared that the longest time between ordering and delivering chips since the record began will slow down the economic recovery that was recovering from the pandemic of the new coronavirus infection (COVID-19). ..

Chip Crisis in'Danger Zone' as Wait Times Reach New Record --Bloomberg

Bloomberg: Chip Delays To Impact Apple's iPad And Mac Lineups

https://www.redmondpie.com/bloomberg-chip-delays-to-impact-apples-ipad-and-mac-lineups/

Chip delays reach crisis territory; Apple, Qualcomm and others are affected --PhoneArena

https://www.phonearena.com/news/chip-delays-are-now-in-the-danger-zone_id132229

Alarming Semiconductor Shortage Pushes Chip Order Wait Times Into The Danger Zone | HotHardware

https://hothardware.com/news/semiconductor-shortage-chip-order-wait-times-danger-zone

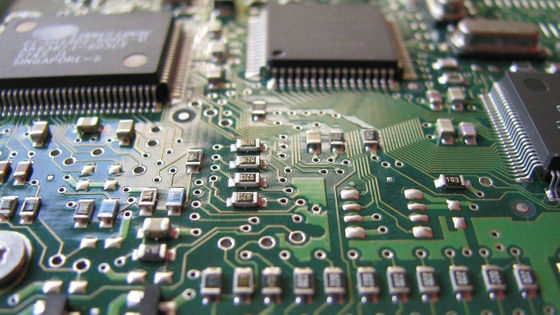

The global semiconductor shortage that originated in the pandemic has had a widespread impact on the production of familiar electronic devices such as automobiles , home appliances , game consoles , and smartphones , and the crisis situation is expected to continue for some time to come. ..

Intel, NVIDIA, and TSMC executives predict that 'the global semiconductor shortage will continue throughout 2021', the worst prediction is 'will continue after 2023' --GIGAZINE

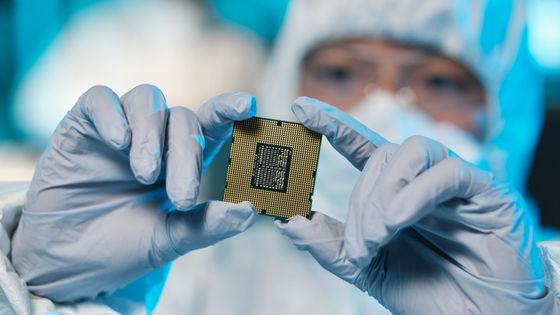

Market research firm Susquehanna Financial Group announced on May 18, 2021 that the lead time from ordering to delivery of semiconductor chips was 17 weeks in April. This is the longest since we started collecting data in 2017, and the company describes this lead time as a 'dangerous area.'

The following is a graph showing the transition of the lead time of semiconductor chips created by Bloomberg based on the announcement of Susquehanna Financial Group. The lead time, which began to deteriorate sharply from the beginning of 2021, was 16 weeks in March and 17 weeks in April, the worst since 2017 when the survey was started.

Chris Roland, an analyst at Susquehanna Financial Group, said in a report, 'Longer lead times often lead to'bad deeds' such as inventory buildup, hoarding, and double ordering.' The overreaction of industry for fear of supply shortages may have spurred the situation, he said.

According to reports, the supply and demand of chips is particularly deteriorating for power management chips, and the lead time in April has reached 23.7 weeks, which is about 4 weeks longer than the previous month. In addition, some industries, such as headphone makers, are facing a 52-week, or one-year, backlog.

'To complicate matters further, the number of COVID-19 patients is rising again in Taiwan, a major chip manufacturing hub. In Taiwan, school and public facilities are closed and assembly regulations are regulated. Companies and factories are open, but the Taiwanese government may have to consider broader regulations in the future. '

For some time, it has been reported that water shortages have hindered semiconductor production in Taiwan. Furthermore, from around the beginning of May, the number of COVID-19 patients has been increasing rapidly from the situation that was ahead of the rest of the world due to the containment of COVID-19, and Foxconn, a major semiconductor supplier in Taiwan, has relocated its production base.The pandemic is rekindling in India, which was earlier, causing great turmoil in the country's semiconductor industry.

IPhone production capacity at Foxconn's Indian factory has decreased by more than 50%, probably due to the infection explosion of the new corona --GIGAZINE

Jim Whitehurst, president of IBM, a major American IT company, said in an interview on May 14, 'Frankly, it will take several years before we have enough production capacity to completely eliminate the chip shortage. I see it. '

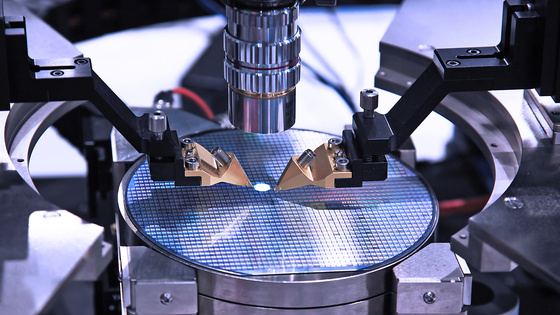

Meanwhile, Hot Hardware, which specializes in electrical news, said, 'TSMC, a major semiconductor foundry in Taiwan, has invested $ 100 billion to improve chip production capacity, and Intel has also 35. The industry is investing heavily, including expanding its plant in New Mexico for $ 100 million, which should eventually improve the situation. '

Related Posts:

in Hardware, Posted by log1l_ks