A robot arm 'RightPick 2' that can perform shipping work in which a wide variety of products flow in place of humans

The demand for online shopping has exploded due to the impact of the new coronavirus , and in March 2020, Amazon announced that it will employ 100,000 new warehouse workers to ship products. However, some Amazon warehouse workers have complained about measures against the new coronavirus, and securing warehouse workers is a major issue both in terms of circumstances and costs. 'Right Hand Robotics' is a company that develops robotic arms that can replace warehouse workers in charge of shipping products for such online shopping.

RightHand Robotics

https://www.righthandrobotics.com/?lang=ja

You can understand what kind of company RightHand Robotics is in one shot by watching the following movie.

RightHand Robotics Peace Picking Solution-YouTube

Robots are already used in many industries, but it was technically impossible to use robots to handle products related to electronic commerce such as online shopping. However, the demand for online shopping is increasing, as Amazon 's pandemic impacted the number of users, such as a series of out-of-stock household items, at Amazon .

In fact, the annual sales of online shopping are increasing by 20%, and the workforce working on site is decreasing.

What is difficult for robots to do is the very simple and repetitive task of 'grabbing and placing items' to ship items purchased through online shopping. In a typical warehouse, this 'grab and place' product is done 10 times before the product is shipped.

RightHand Robotics found a business opportunity there. However, even if it is a simple task to 'grab and place products,' there are millions of types of products that can be purchased online, and it is not clear what products will be waiting for shipment. When you let a robot do the work of 'putting it in place' on behalf of a person, the robot must be able to grab 'products that have never been seen before'.

In other words, RightHand Robotics needed to develop a robot with the intelligence and technology to “grab a high-efficiency (Rate), high-reliability (Reliability), and a huge range (3Rs) of products”. ..

RightHand Robotics forms a team of members such as robotics,

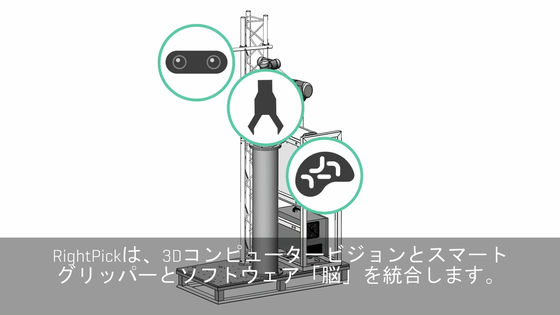

We have developed 'RightPick,' a terminal that integrates 3D computer vision, smart gripper, and software.

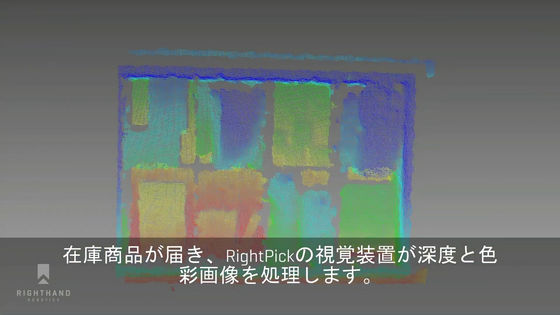

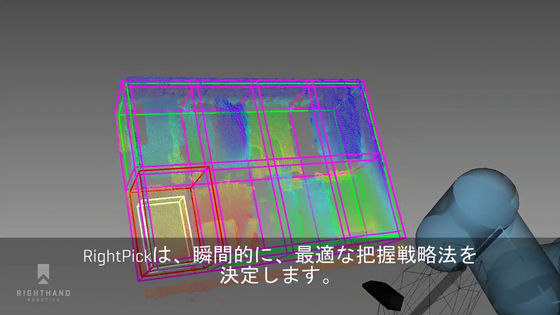

Let's say you want RightPick to actually sort the products. First, RightPick recognizes in-stock products with a visual device and outputs a color image with depth information.

This is the image that contains the depth information that was actually created.

This image is analyzed by a unique division algorithm, and the product that RightPick should grab is selected.

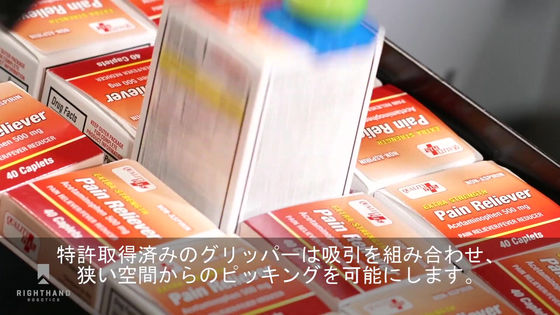

Patented smart gripper for gripping products. There is a suction mechanism at the tip of the gripper, which makes it possible to pinpoint small products from a narrow gap.

This is how it actually picks up. It seems to 'suck up' small products with the power to suck air.

The gripper's finger parts gently hold the sucked product, so you can gently and safely grip products of various shapes and do not drop them.

Then, the image recognition function confirms that 'RightPick has correctly grasped and placed the product.' RightPick is cloud-connected, so all the work of 'grabbing and placing a product' is automatically converted into data and sent to the cardiac learning neural network. And based on this data RightPick can gradually improve performance.

RightPick is already active in warehouses where shipping work is being done all over the world.

By introducing multiple RightPicks, it will be possible to significantly reduce labor costs.

RightHand Robotics has already announced 'RightPick 2' which is the next generation model of RightPick.

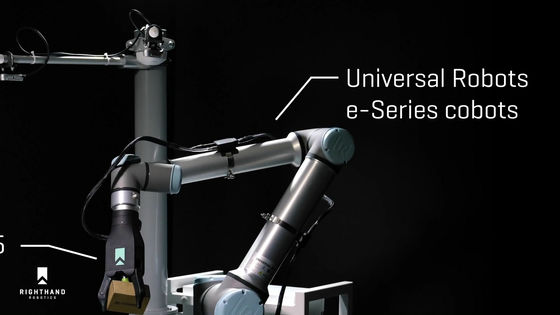

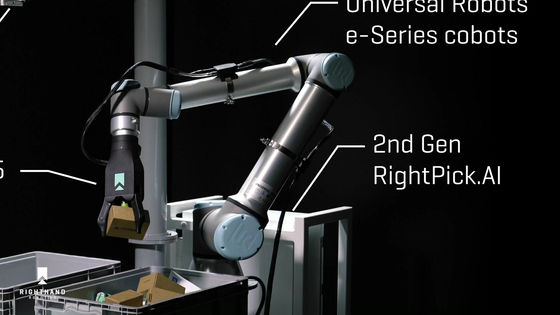

This is RightPick 2. There is no significant change in appearance.

Characteristic smart grips...

Sucker-shaped parts that suck in before grasping the product are also alive.

A camera used for image recognition.

The word 'Right Pick 2' appears on the monitor.

Naturally, RightPick2 can 'grab a large range of products with high efficiency and high reliability.'

The name of the smart gripper part is 'RHR Gripper V5'

The arm part uses Universal Robots

The camera is an

The second generation 'RightPick.AI' is responsible for the software that controls the product gripping operation.

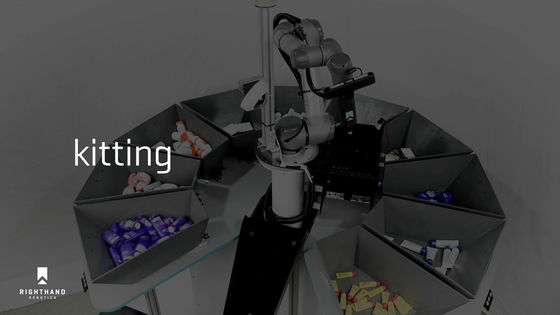

RightPick2 sorts products...

Placement on the wall

Automatic packing

Delivery of products to other robots

Kitting etc. is possible.

Related Posts: