Amazon introduced new robots 'Sequoia' and 'Digit' to its warehouse and succeeded in speeding up inventory identification by up to 75% and order processing by up to 25%

At

Amazon announces new fulfillment center robots, Sequoia and Digit

https://www.aboutamazon.com/news/operations/amazon-introduces-new-robotics-solutions

Amazon's latest collection of robots aims to speed up fulfillments and increase safety - The Verge

https://www.theverge.com/2023/10/18/23922202/amazon-robots-sorting-machines-sequoia-warehouse

Amazon begins testing Agility's Digit robot for warehouse work | TechCrunch

https://techcrunch.com/2023/10/18/amazon-begins-testing-agilitys-digit-robot-for-warehouse-work/

Amazon is reducing the burden on employees by having robots handle highly repetitive tasks at its fulfillment centers. One of the robot solutions that Amazon has newly introduced in order to respond to the year-end sales season in 2023 is ``Sequoia''. Sequoia is operating at a fulfillment center in Houston, Texas, USA at the time of article creation.

Sequoia reimagines the way Amazon manages inventory, making shipping estimates faster and more accurate. This will make estimates more accurate until the product is delivered to the customer, and will also improve the safety of employees working at the fulfillment center. With Sequoia, inventory received at fulfillment centers can be identified and stored up to 75% faster than existing inventory. This means that products can be listed more quickly on Amazon, which will benefit both sellers and customers. Additionally, once an order is placed, Sequoia can reduce the time it takes to process the order through its fulfillment centers by up to 25%. This improves delivery predictability and also increases the number of items that can be delivered on the same day or next day.

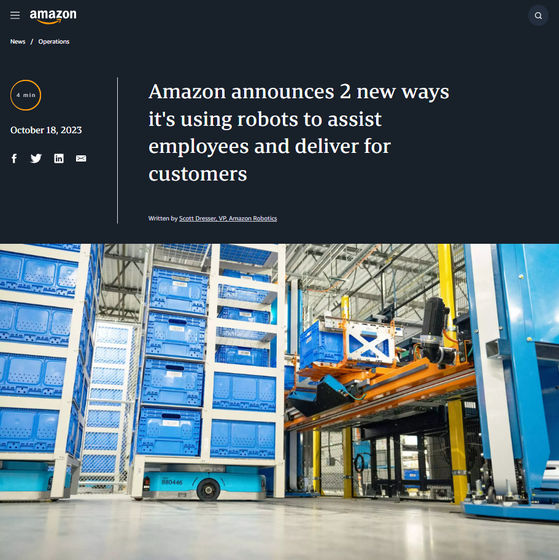

Sequoia is a robotic system that brings together mobile robots, gantry systems, robotic arms, and ergonomic employee workstations to containerize and manage inventory. It works by having mobile robots transport containerized inventory directly from the gantry (a device that stocks containers containing inventory) to workstations.

Containers are handled by employees at newly configured ergonomic workstations. Workstations are designed so that all tasks can be performed from mid-thigh to mid-chest height, which allows employees to regularly reach overhead to retrieve customer orders. This eliminates the need to crouch down, reducing the risk of injury.

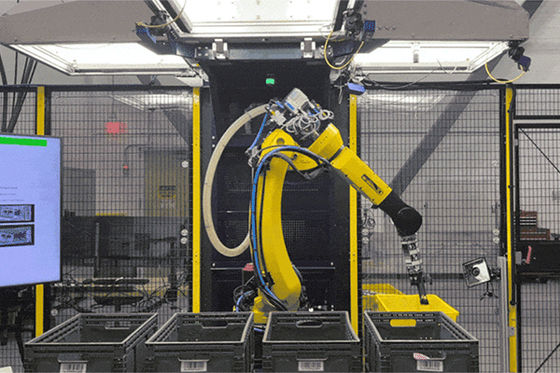

After you pick up the ordered items from the container, you need to replenish the container with the remaining inventory. This work will be carried out by Sparrow, a robot arm already installed at Amazon's fulfillment center.

Sequoia works as a series of integrated robotic systems, greatly simplifying and optimizing the way products are stored, helping employees safely carry out delivery tasks.

Another new robot solution is 'Digit.' This is a mobile robot that can move while grasping and handling objects, and is a new robot that incorporates a mobile manipulator solution. Digit is a bipedal robot being developed as Amazon expands its partnership with Agility Robotics. Agility Robotics is one of the robot companies that Amazon has invested in as part of

Digit is a robot that can move, grasp, and handle objects in fulfillment centers in new ways, with a size and shape well suited to buildings designed for humans, and a robot that works collaboratively with human employees. can work.

The first thing Digit will be responsible for is the highly repetitive process of ``picking up and moving empty containers.'' At the time of writing the article, it will be in charge of very simple tasks, but since it is a robot that can handle various things with a manipulator, it will be able to handle more complex tasks that existing robots cannot handle in the future. There is a possibility that

In addition, Amazon's fulfillment centers exist not only overseas but also in Japan, and of course there are many robots working at Japanese fulfillment centers. You can understand how robots are used at the Amazon Ibaraki Fulfillment Center, which opened in October 2018, by reading the interview article below.

I saw an autonomous robot carrying the entire Amazon shelf on its back at the site of the huge logistics system 'Amazon Robotics' - GIGAZINE

Related Posts:

in Hardware, Posted by logu_ii