I have seen an autonomous traveling robot that carries the entire Amazon shelf on its back at the site of the huge logistics system 'Amazon Robotics'

Amazon Robotics | Amazon.jobs

https://www.amazon.jobs/jp/teams/amazon-robotics

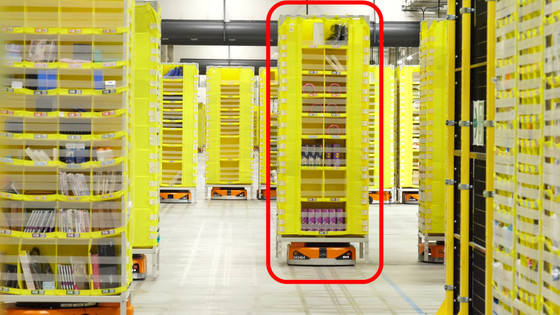

Amazon Ibaraki FC has 4 floors, and there are insanely large warehouses on the 3rd and 4th floors. There are countless yellow shelves in the warehouse, but staff do not move back and forth between these shelves.

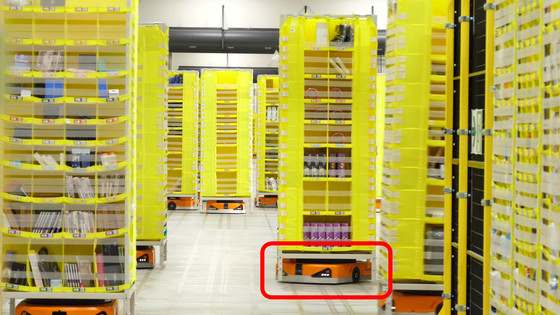

The following autonomous traveling robots called 'drives' play an active role in the warehouse.

The weight of the drive is about 136 kg, and the loadable weight is about 567 kg. In Japan, Amazon Robotics has also been introduced in Kawasaki FC in Kanagawa Prefecture, but it seems that the specifications have been considerably strengthened, such as being lighter than the drive operating there and increasing the loadable weight by about 66%. It looks like a flat car, but this drive slips under the shelf and the black disk on the top rises to carry the entire shelf.

You can see the computer inside from the hole in the center of the disk. It seems that one of the reasons why Amazon introduced robots to logistics systems in the form of Amazon Robotics is that 'making robots solve the heat problem'. If there are people who can do the same job, carbon dioxide and body temperature will keep heat and humidity in the warehouse, and the working environment tends to be poor, but robots can suppress it.

There was a sensor in the center of the front of the car body. This sensor reads and recognizes the QR code drawn on the shelf.

To the right is the Amazon Robotics logo and a number that seems to be the ID of the robot.

Various operation buttons such as power supply were arranged on the other side.

The two-wheeled tires that can be seen from the outside seem to be made of rubber ...

Six months after opening, the tire marks on the floor are already clear. Since humans do not step into the shelf area where the drive moves around, it was impressive that only traces without any disturbance due to the drive remain.

Looking closely at the tire marks, a small QR code was put on the part where the drive decided the turn and the round mark remained. The drive seems to know its coordinates by referring to this QR code.

You can see how the drive actually moves the shelves in the following movie. The operation sound is very quiet as a whole, although there is a driving sound of 'shuin', and the shutter sound of the reporters interviewing around me echoes.

You can see the drive under the shelves moving toward you.

The drive rotates 90 degrees clockwise, but only the drive rotates and the shelves remain the same.

And the shelves went to the left. The drive speed is about 1.7m per second.

For example, even if a fallen PET bottle blocks the drive's path, the drive will recognize the obstacle with a sensor attached to the front in advance, and will search for a route that will not hit the obstacle again and proceed. Therefore, the drive did not stop temporarily to avoid it.

Drive manages inventory shelves, and it is human work to take products out of inventory shelves and store products in inventory shelves. This is the place where 'shelfing' is performed to put products in the inventory shelves.

There is a folding container next to the work place ...

Contains a large number of products. This Ibaraki FC handles items smaller than orange boxes, and many of them are daily necessities, books, CDs, and small household appliances. Ibaraki FC does not handle large household appliances.

Products taken out of the folding container are identified by image recognition by the camera on the monitor. The speed was quite fast, and within a second of taking the product out of the folding container and holding it up, an electronic beep sounded and recognition was completed.

The display next to the worker shows a candidate 'where on the shelf the product should be put', and the worker puts the product in an empty place while referring to the candidate. Style. Instead of the conventional 'fixed products in a fixed place on a fixed shelf', we will manage them according to their size and availability. Managing inventory without deciding where to store it is very difficult, but Amazon Robotics makes it possible.

And this is the place where you can take out products from the inventory shelves.

The drives carry the shelves one after another, so we will put the products in the folding container from the shelves.

You can see how the staff actually puts out the shelves in the following movie. With the introduction of Amazon Robotics, robots carry inventory along with the shelves, so it is possible to greatly improve efficiency by 'the shelves come to humans' instead of 'humans go to the shelves'. ..

Products that have been put on the shelves are also managed by image recognition.

Button to bring an empty folding container to hand

Folding containers traveled back and forth between the 3rd and 4th floors by elevator and were carried on metal conveyor belts.

・ Continued

Related Posts:

in Coverage, Web Service, Hardware, Video, Posted by log1i_yk