I compare how much performance the 3D printers of the tens of millions of yen class have with the performance of hundreds of thousands of yen classes

Even if it says "3D printer" only for hobby that can be purchased for tens of thousands of yen, there are also business machines like tens of millions of yen. A man is using a relatively inexpensive 3D printer and an expensive commercial 3D printer to print out exactly the same parts and compare that deki.

3D Printers: $ 200,000 VS $ 2500

http://additivepartdesign.com/3d/printers/2016/06/01/3d-printer-comparison.html

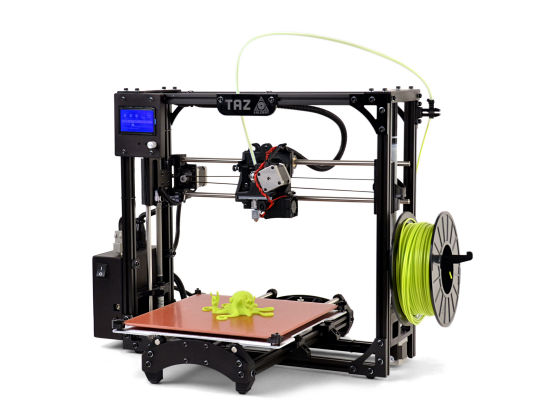

Consulting engineering design using 3D printersMike · Script checkMr. is a relatively inexpensive tabletop 3D printer of $ 2,500 (about 260,000 yen) "Lulzbot Taz 5", 200,000 dollars (about 21 million yen) and expensive business 3D printer"Stratasys Fortus 380 mc"To compare how much difference appears in the output parts.

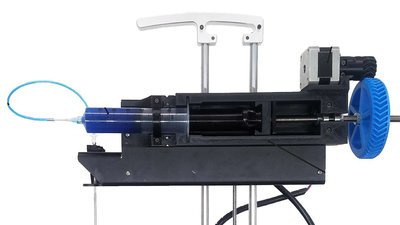

For Lulzbot Taz 5 in the form of a general 3D printer with an open frame ... ....

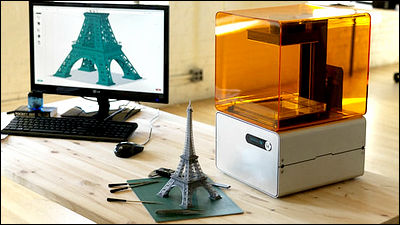

The Stratasys Fortus 380 mc is a huge size with closed workspace, size 1270 mm wide × 902 mm deep × 1943 mm high.

It outputted parts like this. With Lulzbot, impact diameter polystyrene (HIPS) was used as the material, with a nozzle diameter of 0.5 mm, laminating pitch of 0.1 mm, printing speed of 45 mm / s. On the other hand, Stratasys used ABS resin as a material and actually outputted it, it seems that it took about 18 hours on either machine.

First of all, it is a part outputted with inexpensive Lulzbot.

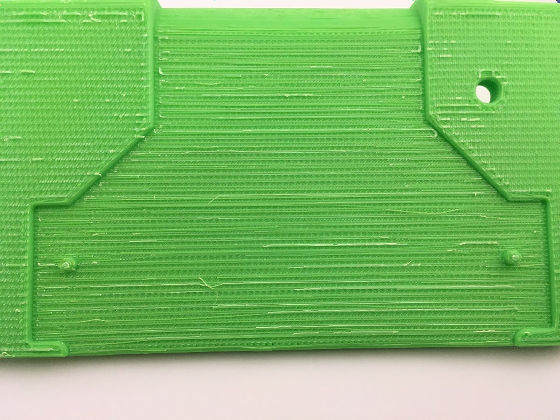

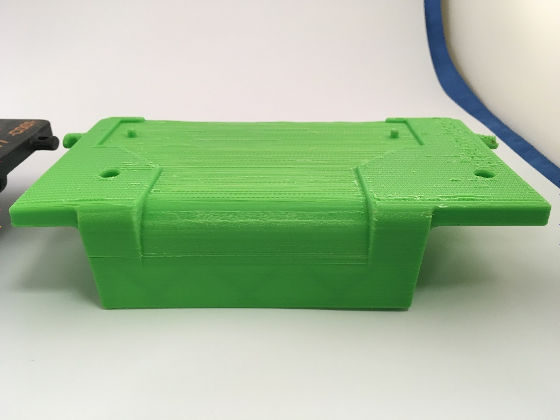

On the back side, by making parts called raft (raft), precision is raised by preventing part warping.

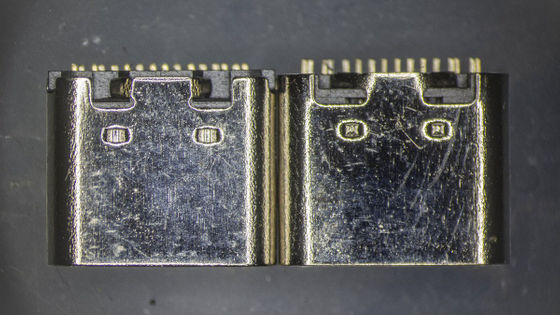

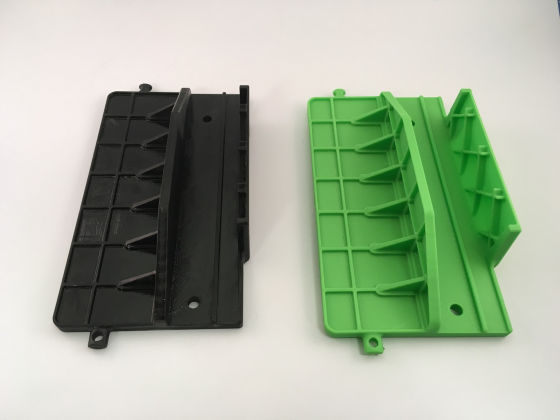

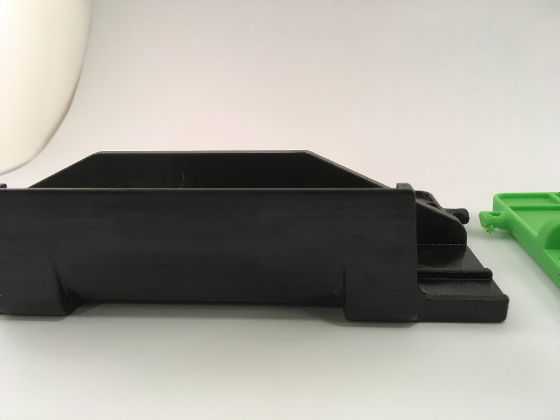

In the state of the finished product with the raft removed, try to arrange it with the black parts output by the high-end machine Stratasys. It is almost impossible to understand the difference at a glance, and both parts are accurate to function properly.

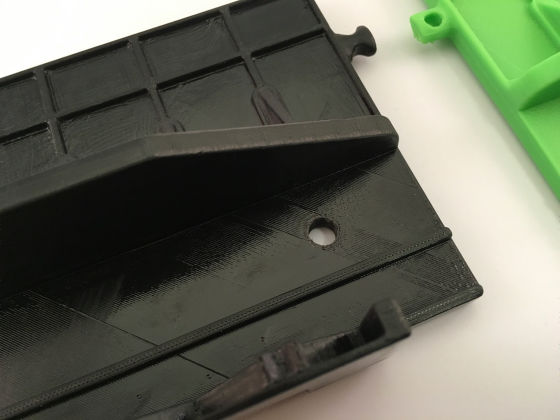

Then compare details. Looking at the parts jumping out of the edge and comparing ... ...

In Lulzbot the lower half was crushed. Since the upper half was output correctly, it was certain that there was some trouble with the output of the lower half, but I did not see the reason because I was not observing the output halfway. However, in terms of the top half that is output correctly, ScripCheck says there is little difference.

In the finish of the surface, Stratasys can see the layer a little bit ... ...

Lulzbot is smooth.

The big difference is the bottom contacting the pedestal. When Lulzbot peels off the raft, a small burr-like "burr" occurs.

On the other hand, Stratasys is a smooth finish because it is designed to wash parts that support parts by applying special salt water. There is an advantage that polishing work can be minimized.

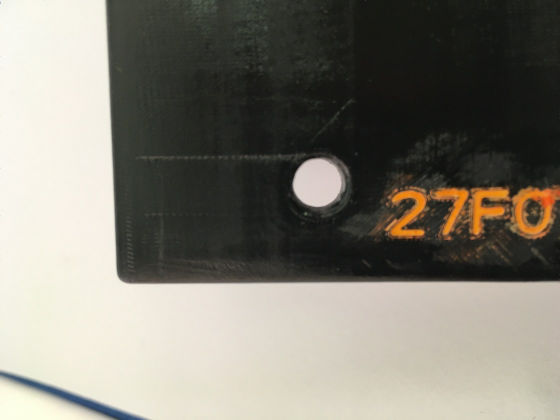

For parts output by 3D printers, "part number" of parts may be printed for convenience in assembly and use. With Lulzbot a model number is like this.

On the other hand, Stratasys can improve visibility by orange coloring the model number. The convenience around here is a high-end machine.

I will look at the part from the side. This is Stratasys.

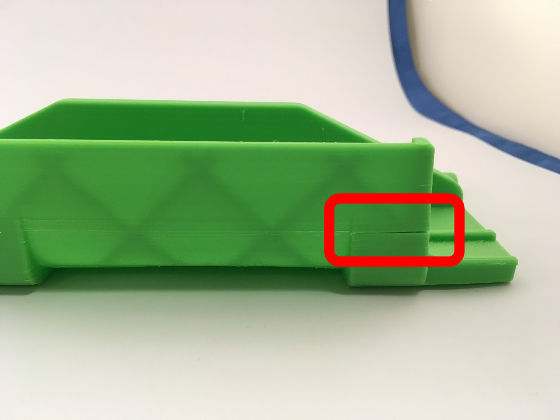

In Lulzbot, gaps like cracks formed by pulling parts into the part surrounded by a red frame. However, Mr. Scrippecheck judges that there is no problem because it will fill up if it is a gap of this, if it kneads the material and pressurizes it.

When comparing the curved parts, against a very smooth Stratasys ......

Lulzbot can see a lot of lines.

As a result of comparing and outputting the same parts with hundreds of thousands of yen 3D printers and more than 10 million yen 3D printers, it is certain that there are differences between high-class machines and popular-price machines in terms of looks etc. , There is no significant difference in quality, Mr. Scripcheck says. Also, even with relatively inexpensive 3D printers, it is said that by adjusting nozzles and G code data, there is also a response that quality near the high-end machine can be obtained. Mr. Scripcheck concludes that hundreds of thousands of yen 3D printers are sufficient, except in cases that require outright accuracy.

Related Posts:

in Hardware, Posted by darkhorse_log