A 3D bioprinter that can be introduced at a price of just 50,000 yen appears

3D bioprinter which can produce cells etc is original specification with closed source, in addition to 10,000 dollars (about 1.1 million yen) at low price, as well as 200,000 dollars (about 22 million yen) if it is expensive. In order to manage this situation, the research team of Carnegie Mellon University has created a 3D bio printer that can be made for $ 500 (about 54,500 yen). If you already own a 3D printer, it seems OK with parts exchange of just 50 dollars (about 5500 yen).

Large volume syringe pump extruder for desktop 3D printers - ScienceDirect

https://www.sciencedirect.com/science/article/pii/S2468067217300822

Carnegie Mellon Designs Low-cost, High-Efficiency 3D Bioprinter | RoboticsTomorrow

https://www.roboticstomorrow.com/article/2018/05/carnegie-mellon-designs-low-cost-high-efficiency-3d-bioprinter/12016

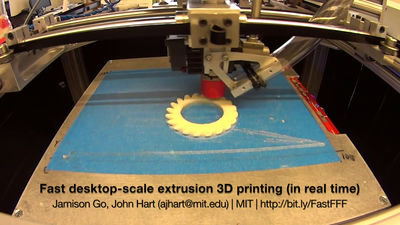

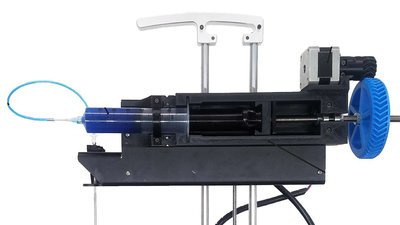

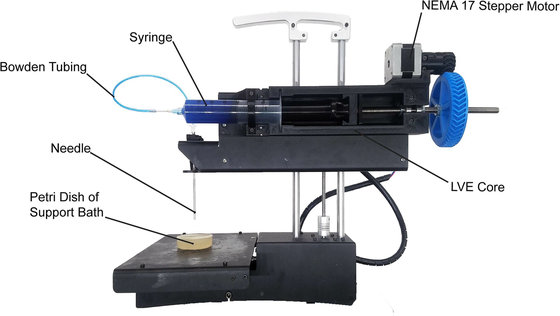

Carnegie Mellon University created precisely " Large volume syringe pump extruder (LVE) for desktop 3D printers ".

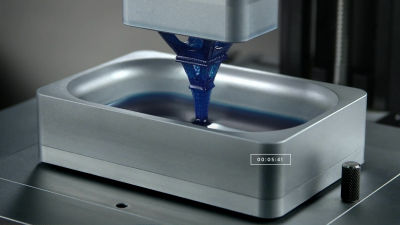

Generally, 3D printers equipped with syringe pumps can be divided into "bio-printers" and "paste / clay extruders".

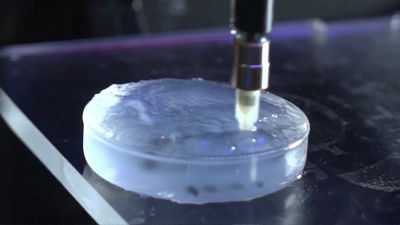

"Bioprinter" is intended for high precision printing of cells and the like. It is characterized by having a small volume syringe of 10 ml and a small diameter nozzle of less than 250 μm because the object to be printed is small.

On the other hand, the "paste / clay extruder" has a large capacity reservoir and a large-diameter nozzle of 4 mm at maximum. Clay, ceramics, composite resin, cement etc can be handled, but basically it is "to make something of simple shape with slow printing".

LVE made by Carnegie Mellon University can print with various materials including biopolymer, hydrogel, paste and epoxy. By using standard syringe with a size of 60 ml size, cost reduction is realized, and as a bio printer, large capacity is realized. On the other hand, it has achieved high performance as a paste / clay extruder.

Also, many syringe pump loaded printers had a problem of material leakage due to "retreat" during printing between layers and layers, which reduced the accuracy of the finished product, but LVE Is precise material extrusion, material leakage due to retreat does not occur, it is possible to output sophisticated and complicated objects.

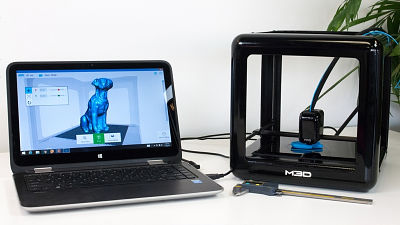

Furthermore, since this LVE is designed to correspond to a general tabletop 3D printer, if you already have a 3D printer you can install it for as little as $ 50 (about 5500 yen). Even if you do not have a 3D printer, the total installation cost will be 500 dollars (about 54,500 yen). Since the design of the parts is published according to the paper, it is possible to create it by oneself if there is only a 3D printer.

Professor Adam Feinberg, who developed the project, launched a research laboratory in 2010 and devised a method to output artificial heart parts without collapsing by self weight with an inexpensive 3D printer of 100,000 yen class . Due to the fact that commercially available bio-printers are so expensive, we purchased MakerBot's 3D printer and used it as a 3D bioprinter by replacing the extruder.

Related Posts:

in Hardware, Posted by logc_nt