A fierce man who made his own tourbillon clock with a 3D printer, appeared, released parts data and assembling methods etc.

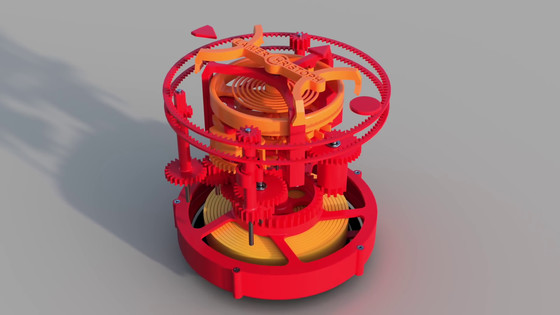

At the heart of the clock is "TempThere is a part that produces a certain vibration called " Although this temple is easy to be affected by gravity, a complicated mechanism that can eliminate the influence of gravity by incorporating it in a part called a rotating carriage and improve the accuracy of the clock is called "Tourbillon"is. The wrestler that made such a Tourbillon mechanism appears as a bizarre who made herself with parts outputted with a 3D printer. Also, since this watch is open to parts data and how to assemble all parts, it is also possible to output the parts with your 3D printer and make your own.

3D-printed Watch with Tourbillon - How it's made - YouTube

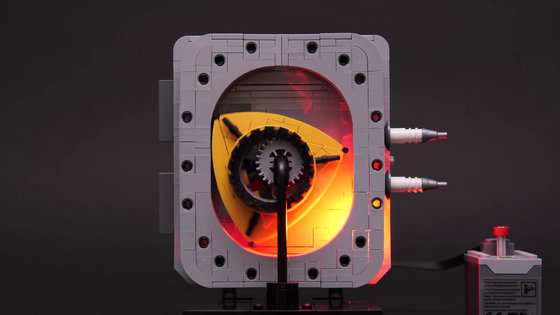

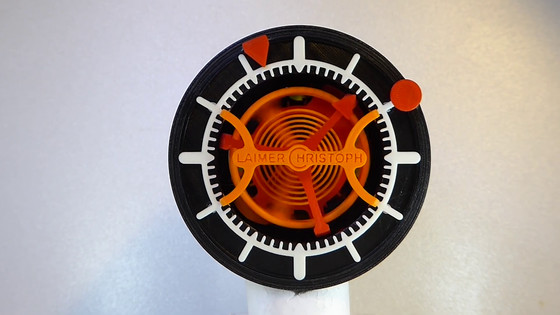

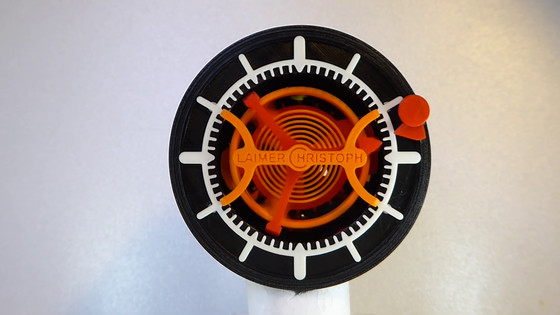

This is a watch created with a 3D printer. Although it looks like a clock, it is an imminent clock with three seconds, a minute hand, and an hour hand.

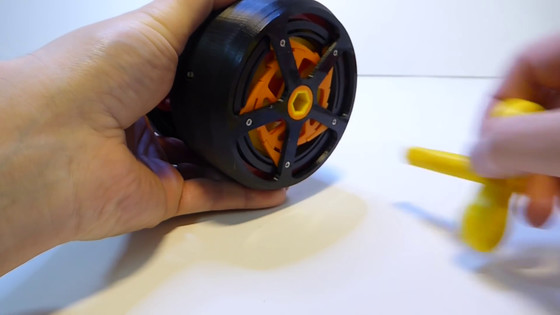

The power of the watchSpiral springThen, if you insert a dedicated handle on the back of the watch and rotate the watch, it will move. It seems that it will operate for about 35 minutes at a time, but if it is replaced with a one made from a steel printer outputted from a 3D printer, it can also be operated for a longer time.

The clock moves like this. It is characterized that the movement of the inside can be seen also from the front of the clock, either because the tourbillon mechanism is adopted, the error in 1 minute is less than 0.5 seconds.

A hole is also opened on the side so that the internal structure can be observed from various angles.

Also, because there is a strap hole at the top of the clock, it is convenient to carry if you pass a chain etc. here.

As you look inside, you can see that things like a mainspring are moving around. However, in fact there is a longer and thicker spring spring inside. The "LAIMER CHRISTOPH" carved in the middle of the clock is the name of the author of the clock.

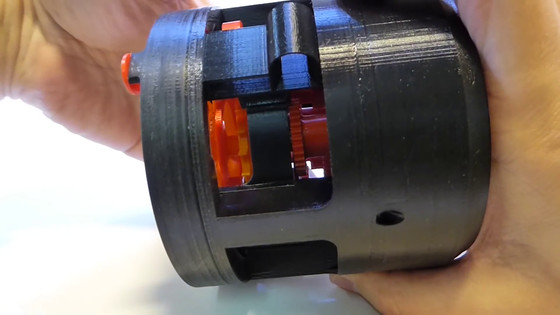

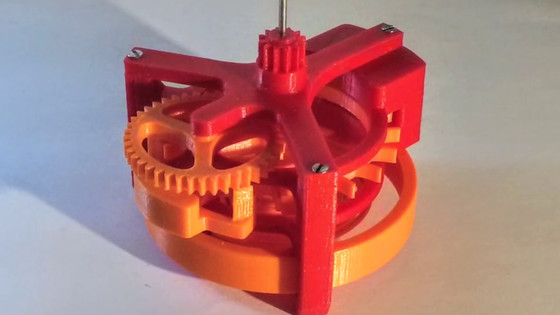

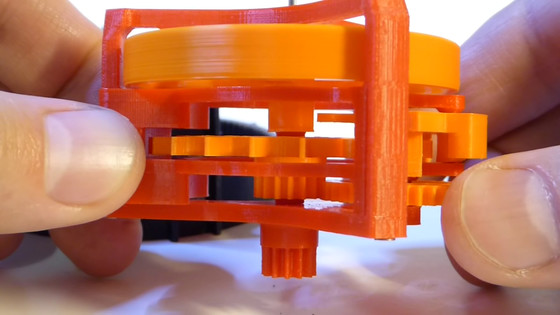

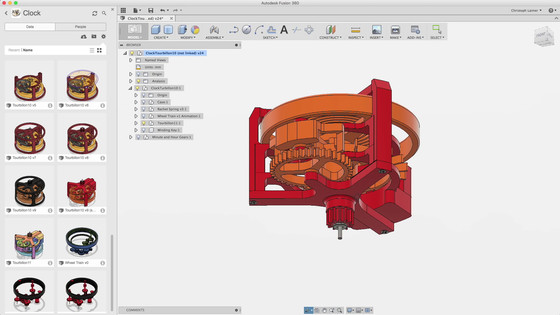

Disassemble parts and check internal mechanism.

This kind of gear folds multiple gears into a clock.

If one gear is rotated, other parts also rotate in conjunction.

The number of parts is actually 51, and it is necessary to prepare screws and shaft separately in addition.

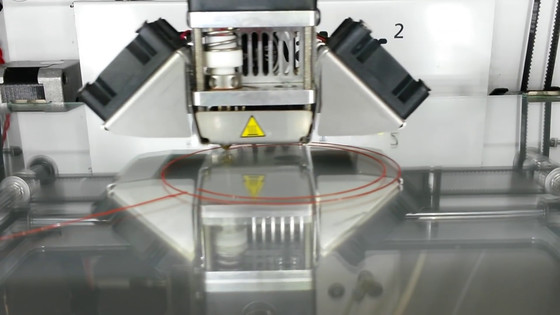

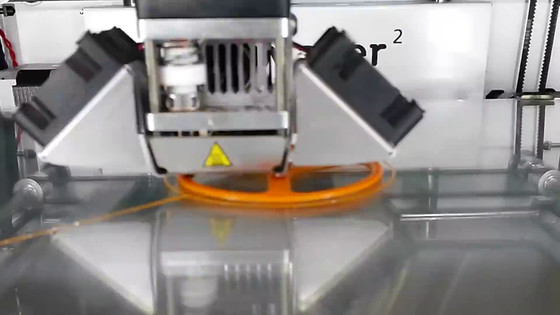

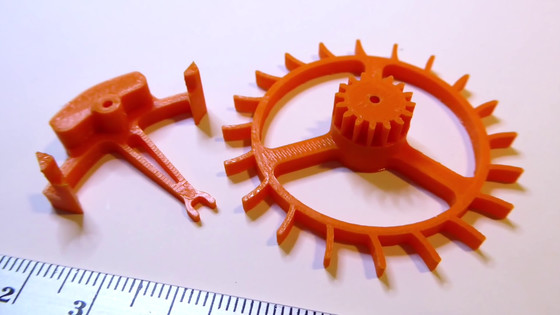

If you look carefully, you can see that screws are used for part of the parts. Most of the parts are output with a stacking length of 0.1 mm and a pitch of 0.8 mm, but the hairspring, the escape wheel and some gears are output with a resolution of 0.06 mm and a pitch of 0.8 mm pattern. In addition, it seems that the case part of the watch uses PETG material resistant to bending and shock, and the gear part uses plastic material.

The white frame is a dial, the red circle is the hour hand, the red triangle is the minute hand, the arrow shaped part inside the white frame is the second hand.

Each part is "3D CAD software"Fusion 360Create with.

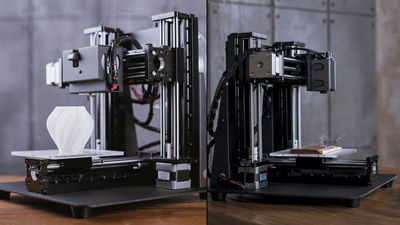

This is output with a 3D printer. Author Christoph Laimer,Ultimaker 2It is said that it outputted it using a 3D printer.

The outputted parts look like this. There is roughness on the surface which you can see as outputted by a 3D printer when you look closely.

It is necessary to prepare several screws, shafts and washers separately from this part.

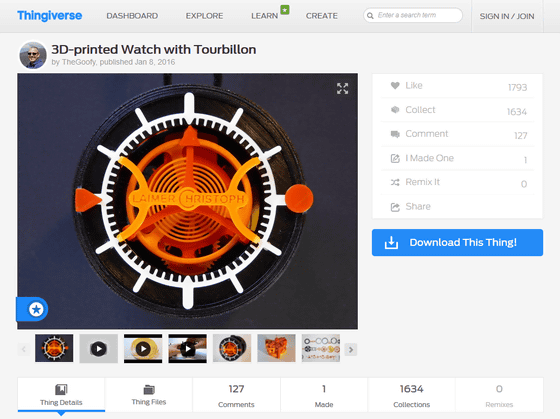

Christoph Laimer of the author created each part of the clock using Fusion 360, but its 3D model data is released collectively on the following pages.

3D-printed Watch with Tourbillon by TheGoofy - Thingiverse

Furthermore, the assembly procedure after the parts are output is introduced in the following animation movie.

3D-printed Watch with Tourbillon - Assembly Animation - YouTube

If it is not easy to understand with animation, check the following movie which was filmed as a time lapse movie when Christoph Laimer actually assembled it.

3D-printed Watch with Tourbillon - Assembly Time Lapse - YouTube

Related Posts: