Designers explain Apple's sticking to the production movie of Apple Watch

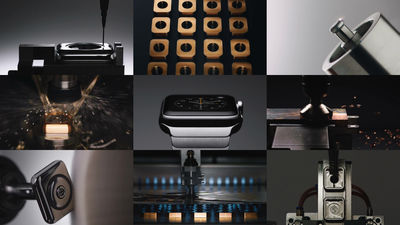

A movie that understands exactly where Apple has made three models of aluminum, iron and gold "Apple Watch"Apple has published it on YouTube, but this movieIndustrial designerLooking at it, it seems that "Apple's commitment" which is not told in the movie seems to be more detailed.

How Apple Makes the Watch - Atomic Delights

http://atomicdelights.com/blog/a-glimpse-at-how-the-apple-watch-is-made

Industrial Designer Explains Production Methods Shown in Apple Watch Manufacturing Videos - Core 77

http://www.core77.com/posts/34524/Industrial-Designer-Explains-Production-Methods-Shown-in-Apple-Watch-Manufacturing-Videos

An industrial designer, Greg Koonnick, who took a look at the movie published by Apple and explained about the part not being talked about in the movie. There are three models of Apple Watch, "Apple Watch", "Apple Watch Sport", and "Apple Watch Edition", but each movie explains Apple 's commitment, which is known from the manufacturing process movies of each model.

First of all, comment from the production movie of the high-end model "Apple Watch Edition" using 18 gold.

Apple Watch Edition - Gold - YouTube

Mr. Kunick noted the following scenes. It is a scene that inspects metal parts with ultrasonic scanner.

Looking at this scene, Mr. Khunik said "In this scene, Apple is doing inspection of whether or not bubbles are entering metal parts.If pressure is applied, things with uneven density and surface defects We find something and remove them before processing.This ultrasonic scanner is usually a high precision used when inspecting rotating parts used inside medical implants and aero engines In addition to taking a very long time, it is costly to investigate using custom machines, so it costs huge. "

Next is the manufacturing process movie of stainless steel "Apple Watch".

Apple Watch - Steel - YouTube

In the movie, you can see a scene to scrape metal parts with a 5-axis milling machine, but Mr. Kuhnik notes this scene. In this scene various parts are milled, and it seems that you can see something that finishes more elaborate housing parts.

Also, Mr. Knick says, "If you look at the finish of the movie and Apple Watch, you can see that Apple would have spent enormous cost and time in automatic polishing." Particularly, it is inappropriate for a soft buffing material to finish the edge part shiny, and it is necessary to use exclusive abrasive material.

Also, Mr. Kunick has assumed that what is used when polishing the crown and power buttons is a polymer plug that Apple would have developed independently, so that it is precisely the body I think that it is possible to polish.

Finally the manufacturing process of "Apple Watch Sport" made of aluminum.

Apple Watch Sport - Aluminum - YouTube

Mr. Kunik said that one of the world's leading technologies possessed by Apple is "laser processing technology".

Occurs during machiningBariIs usually about 0.05 mm thick, if it is left it can not fix the parts straight, parts can not be measured correctly, it leads to injuries and accidents.

Normally this burr is scraped off with a very small tool or manual work, but Apple is doing deburring with something like leather, "This process is very unique," said Kunic He says.

Related Posts: