"Project Longhaul" to make a ring with built-in LED to tell her love

The maker of the producer decides to meet with a woman, fall in love, think about what to do in order to convey his own thought, design the complex ring as much as possible by himself, then for about four months , I keep making rings.

KdN - Kokes dot Net

http://www.kokes.net/projectlonghaul/projectlonghaul.htm

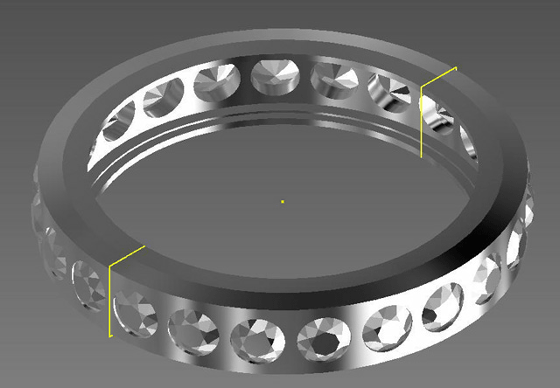

The final design of the ring was decided in January 2013, trial and error on materials and design, designing what is not simple but you can make. The final design was to embed a combination of LED and copper coil inside the titanium ring and the LED would shine from under the stone attached to the ring as it approached the transmitter.

Autodesk InventorWe also use 3D modeling software to design the 3D model of the ring and also succeed in knowing that the size of the finger of the opponent passing the ring from the collaborator is 15.72 mm.

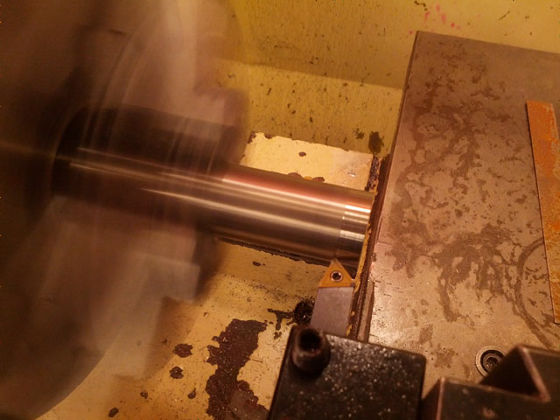

Titanium is harder to handle than using aluminum or steel, and when cutting or processing titaniumCemented carbide toolMust be used.High speed steel toolCan be processed using, but it will wear out quickly wear out.

Rings are made from titanium rods. The outer diameter of the ring is 19.8 mm, and the ring part is scraped so that there is a margin of about 2 mm between the inner diameter and the outer diameter.

When opening the part to pass the finger of the ring, it seems that the drill is not greatly shaken by cutting with a small drill and then cutting with a large drill first.

Because the heat conduction of titanium is not good, heat concentrates on the drill bit which is the tip part of the drill, and the tip becomes too hot, so the edge part of the drill bit melts like this picture and it is not usable.

When opening the part to pass the finger of the ring, make a hole so that the hole becomes 15.8 mm. In order to put electronic equipment, it seems to have made it a little weaker than the size of her fingers passing the ring.

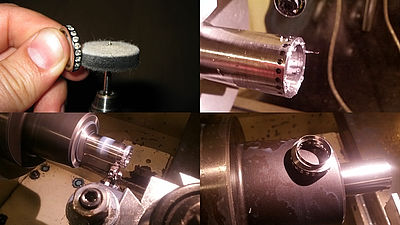

I will leave 23 holes in the ring by stepping through the three processes. First make a hole with a 0.8 mm drill, make a hole to serve as a guide for making a bigger hole ... ....

Next, relying on the hole in the guide, use a 2 mm drill to create a hole in the ring.

Finally, we cut out a place to place the stone on a 2 mm hole with a 2.3 mm drill.

Until so far, we finally cut off the ring part from the titanium rod. If you remove the ring part from the titanium rod before the hole making step, the ring may be broken when opening the hole, so I will go with caution.

Where the titanium ring was removed from the bar.

Next time it seems to make space for built-in electronic parts.ColletWhenMandrelWith the ringlatheFixed to.

O-ring grooveUsing the equipment to make, engrave a groove of width 2 mm deep 1 mm inside the ring. This groovePermalloyIt will be part of the alloy and space for storing the coil and the LED.

Cutting the position of the stone cut the space between the parts that store the stones, because the arrangement of the stones becomes cleaner and it fits well. It seems that it was very difficult to fix the ring so that it does not move during this cutting.

Metal working The last step is polishing. For polishing, use a microscope and do three strokes. As I made using a carbide tool, the ring has some sharp and pointed parts. To remove this, use a sandpaper with a particle size of 1200, thenDREMELIntoRotating plate of feltI polished it with. After washing away garbage onceRYOBI's metal polish setuse.

I tried several methods to fix the stone to the ring, but none of them led to the damage of the ring or stone. I finally used itEpoxy 330The adhesive.

I glued 13 white stones and 10 blue stones to the ring.

It seems that creation of the electronic equipment part is relatively easy. Create a coil to attach to the groove part of the ring.

Expanding the coil part looks like this

Creating the coil part is now complete.

Circuit diagram of transmitter circuit.

Cut the transmitter circuit on the copper plate.

We will move on to creating transmitter coils.

A transmitter device attached to the arm is completed.

The transmitter is well hidden under the clothes.

It glows when the ring approaches the transmitter.

If you make it without making a cut in the ring, the coil will not shine when the coil is put in the ring.

The following movie shows you the phenomenon that the coil does not emit light when the ring that does not actually cut it approaches the coil.

Magnetic Field Cancelation - YouTube

It seems that grooving and cutting are carried out and it has become possible to work well by putting permalloy alloy in this groove.

In the following movie, you can see that the ring succeeded as if the ring glows even if the ring is placed closer to the transmitter with the coil inside the ring.

Ring Illumination - YouTube

The long bar was the titanium rod used as the base of the ring and the shorter one was the aluminum bar used for various tests. The ring most recently made is at the left end, this is the tenth prototype as a ring of titanium.

The producer handed the ring to her and on the next day he said he went to buy a ring made by a professional jeweler. But there she asked the producer to redo the ring once more than to buy a ring. The reason is that the inner diameter of the ring made by the producer is 15.6 mm and it is because it was smaller than 15.72 mm which is the size of her finger.

The producer said that in the near future she will have a better ring that she designed.

Related Posts: