A fierce man who made his own by scraping out the aluminum mobile device used by the investigation corps at 'Advance Giant' appeared

Popular comic book that broke through 36 million copies issued copies of books "Attack on Titan"Three-dimensional mobile devices developed in order to challenge melee combat to the giants who are many times larger than ourselves in the work of mankind. In order to build such a three-dimensional mobile device using aluminum, stainless steel and so on, a fierce person who made the blade part finish with ridiculous quality at first and revealed its production process appeared.

Ratan Technical Laboratory Full Metal Three-dimensional Mobile Device Completed (with animation)

http://joshualawn.blog.fc2.com/blog-entry-90.html

This is the blade part of the three-dimensional machine tool made from aluminum scraping. It is exactly the work that you saw in the picture and the blades themselves were swaying by the survey team to defeat the giants.

The grip part is made of wood called Agachis, the other part is made of aluminum and stainless steel. Each lever, trigger, and hammer part near this grip is operable.

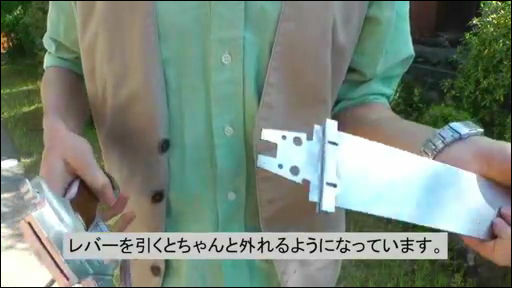

Although the blade part is not easy to come off easily ... ....

Pull the lever in front ......

You can remove the blade part. It is safe even if the sharpness of the blade worsens by knocking down the giant if this is done.

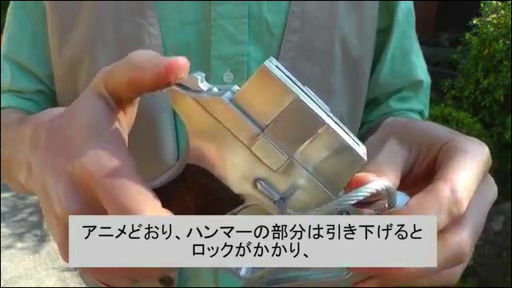

Also, the hammer on the handle part of the anime street blade is locked when pulling it down ......

It seems that the hammer seems to fall by pulling the trigger that comes to the part of index finger.

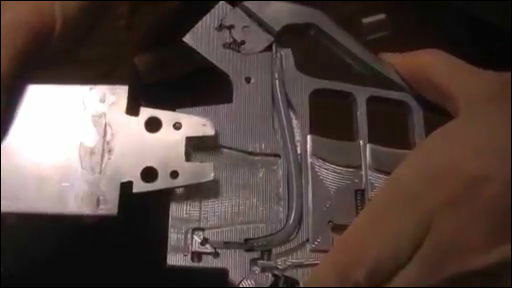

The handle of the blade is made up of two aluminum plates, and the operation gimmick of each part is packed perfectly on one side.

Inside there are six springs, 12 parts and 3 electric switches. Since the electric switch is not used in particular, it seems to be something you intend to use when creating the body part of the three-dimensional mobile device.

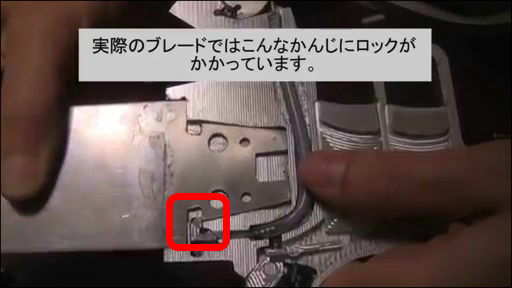

The handle of the blade and the blade are fixed with the metal of the red frame part locked.

This lock part is connected by a lever and a wire, and pulling the lever makes the lock come off.

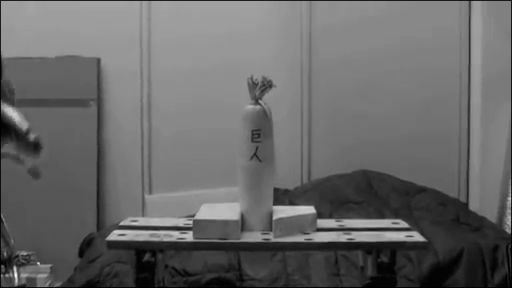

Although it is a blade that has become quite elaborate, it is also possible to cut a giant (radish) by cutting a momentum.

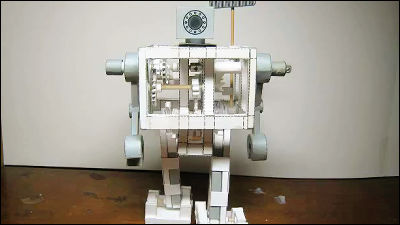

It is like this when arranging along with the wooden three-dimensional mobile device which the creator Mr. Tan made with "wood" before. Where the shooting place is not the veranda but the side of the stone wall or something it is likely to become outstanding atmosphere.

In addition, if I make this blade, Mr. Tan has uploaded the production process to YouTube and Nico Nico Douga and you can see how much trouble you have to make to make this quality item with aluminum scraping .

I tried fully metalized three-dimensional mobile devices [sword editing] - YouTube

I tried to convert three-dimensional mobile devices to full metal [sword editing] - Nico Nico Douga: GINZA

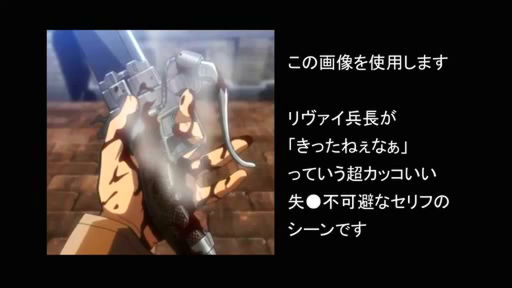

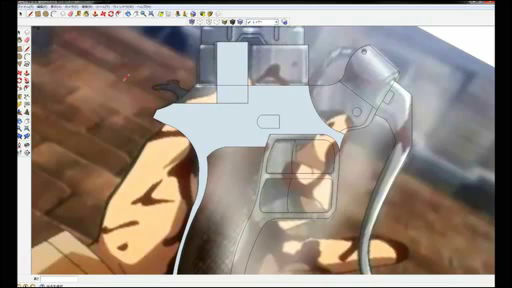

The handle part of the blade is created by tracing one scene of animation.

Trace the handle part like this ... ....

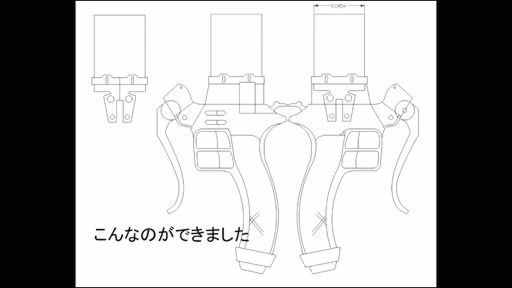

Drawing is completed.

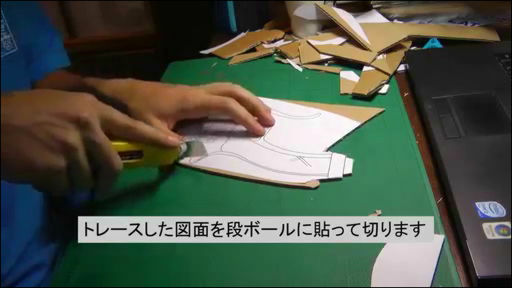

Next paste the created drawings on cardboard ... ...

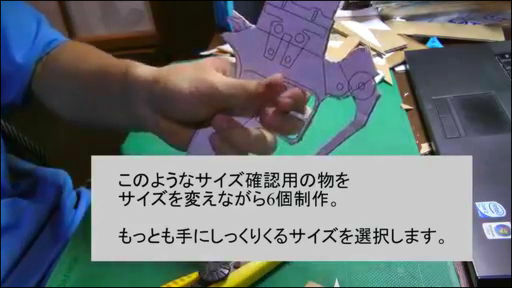

Choose the size that will fit your hands.

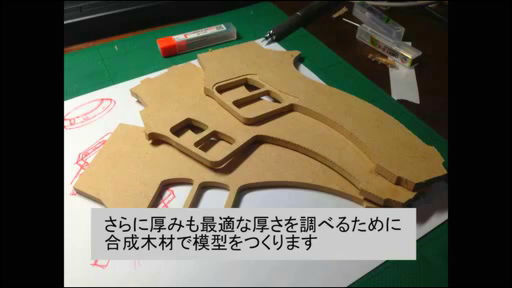

Furthermore, in order to investigate the optimum thickness of the pattern, we make a model with synthetic wood.

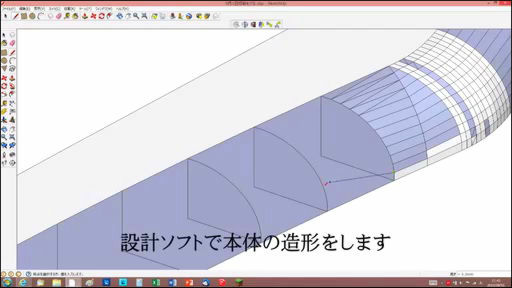

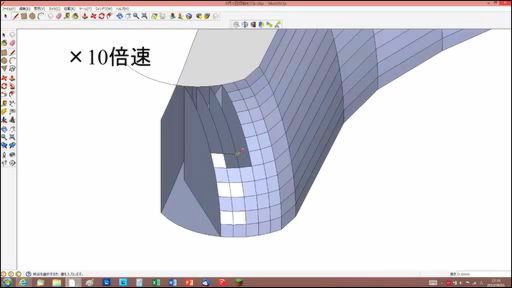

After deriving the pattern part of an appropriate size feeling like this, I will use CAD to finish the detail of the pattern.

After considerable fine work continued ... ...

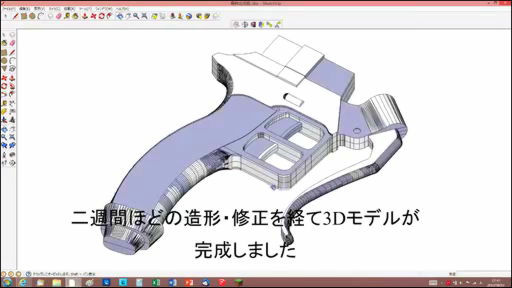

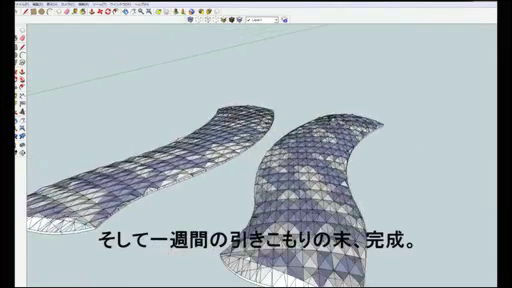

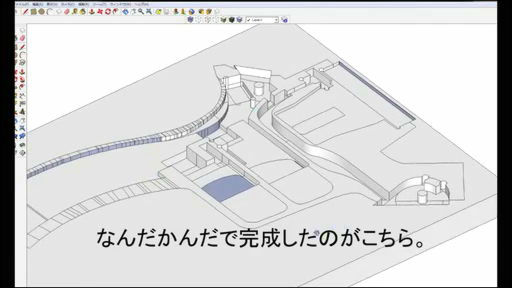

It seems that the 3D model has been completed in about two weeks.

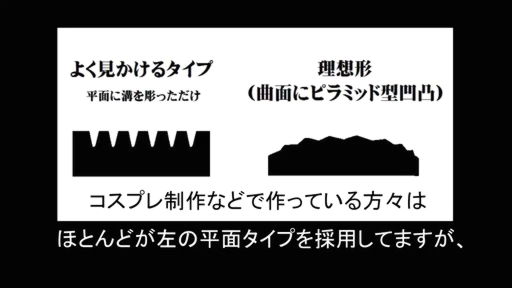

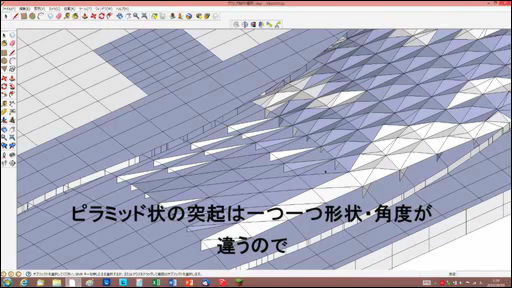

The decoration of the trees of the grip part seems to be created not only by carving the grooves on the plane, but by carving pyramid-shaped concavities and convexities on the curved surface ......

In order to create a 3D model, it is a type of raging that carefully finishes the shape of each protrusion.

It took about a week to create this part. How long does it take to create two blades?

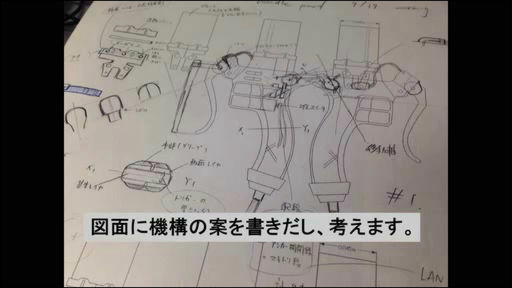

Now that the exterior of the handle part is completed, the next is considering the idea of the internal mechanism ......

It seems like this is completed also in somehow.

The handle part is made up of two metal plates, and it seems to carve these gimmicks on one of them.

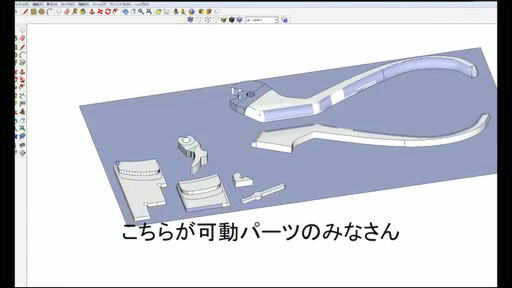

In addition, 3D models of movable parts are also crispy.

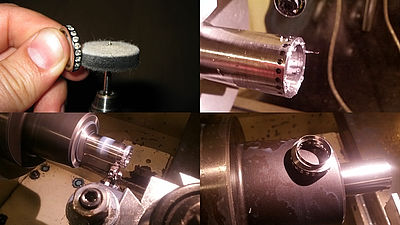

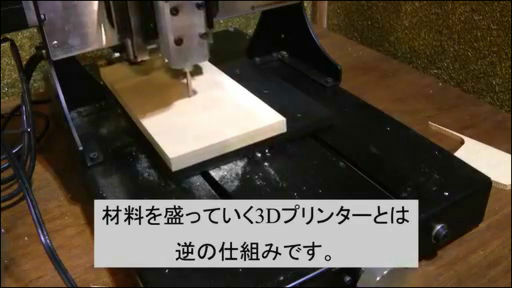

Once we have reached this point, we will move on to work to cut parts from the aluminum plate. CNC milling machine is used for cutting parts.

With this, it becomes possible to cut materials and make parts as programmed. However, it is a device that fails quickly with a slight mistake or the tip part breaks.

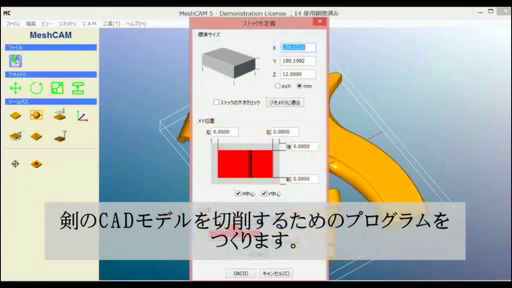

Then, make a program to cut the CAD model of the handle part, load it into the CNC milling machine, and start cutting as soon as you finish the various settings.

After that the CNC milling cuts the aluminum plate roughly. The time required for cutting is about 30 hours.

Cutting is completed. We will also cut other parts with this condition.

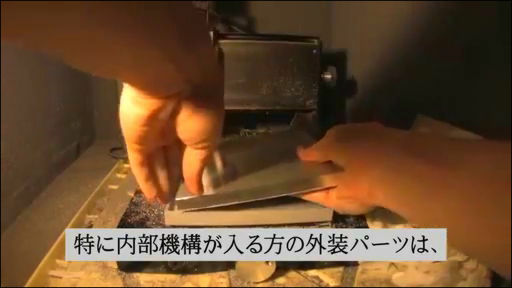

The side on which the internal mechanism enters must have both sides cut.

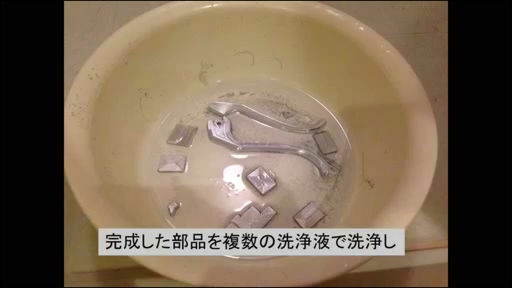

Clean up the parts that were scraped off like this with multiple washing liquids ......

It was completed like this.

Here is the main part.

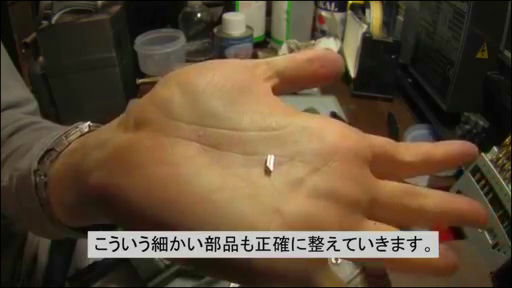

There are also such small parts.

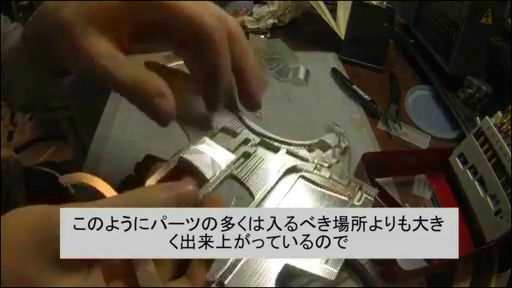

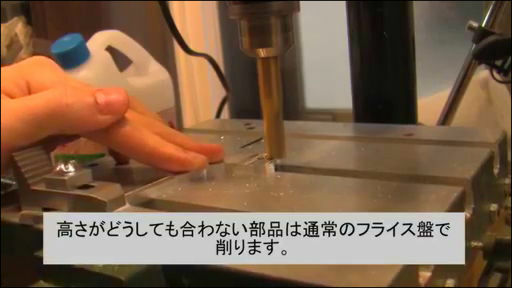

It seems that each part is being cut larger than the place where it fits ... ...

It is going to be scraped down until they are perfectly sized with a bar file.

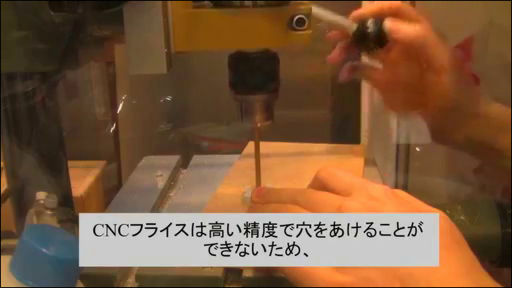

Also, CNC milling machines can not drill holes with high accuracy, so it seems that the holes that can not be opened by this will be emptied separately using a drilling machine.

In addition to this, every time a problem arises, it is ok if you deal with any tool or equipment.

And put the wire in the lever part ......

If you also insert a switch, the internal mechanism for the time being is complete.

In the end, screw holes are made in the main body ......

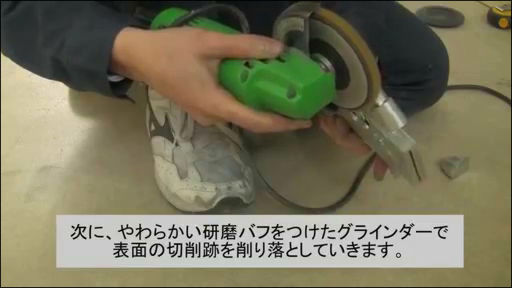

Clean the cutting marks on the surface with a soft polishing buffed grinder ......

And if you keep polishing just about an hour with metal polishing liquid, all the metal parts of the handle part will be finished.

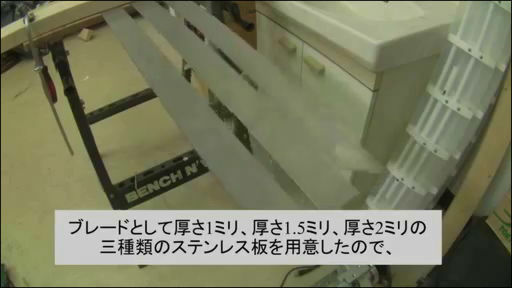

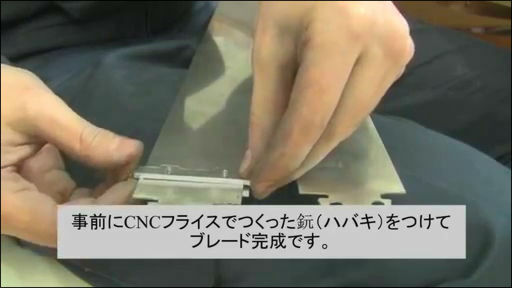

Continue to create a blade to attach to the handle. We used a stainless steel plate for the blade, and it seems that the thickness was created from three types of 1 mm, 1.5 mm 2 mm, 1 mm and 1.5 mm.

We will also cut the guns.

And I made it in advanceHabakiIf attached to the blade is completed.

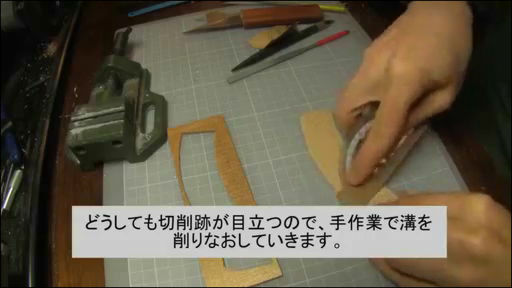

Finally finish the wooden parts of the grip part. It seems that this part was also cut by CNC milling machine for about 8 days (close to 200 hours), but the cutting trace seems to be quite rough, and the part of the groove is being shaved manually.

When the pattern part becomes so beautiful ... ...

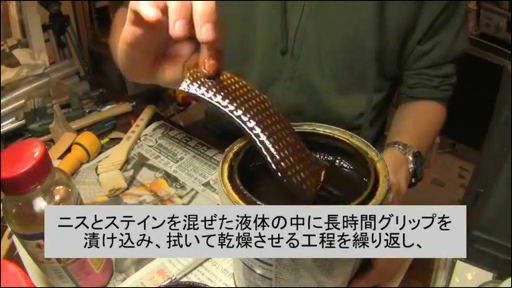

Immerse in a liquid mixed with varnish and stain for a long time, and color the grip.

Such a grip became such feeling like this.

Combining the parts completed in each process completes the blade like this. Is cheers for good work.

According to the maker of the producer, in these processes, the milling machine end mill (about 2,500 yen) broke 30 or more, and 21 sheets of aluminum board (12 mm thick one about 2300 yen) was consumed due to repeated failures And it seems that the total amount of about 500,000 yen disappeared from the wallet. In addition, it seems there was a final notice from the waterworks bureau, and it can be predicted that there was a fierce battle that can not be transmitted by just watching it in the movie.

Related Posts: