How to make your own wedding ring to suit your fiancé's taste

Software engineer

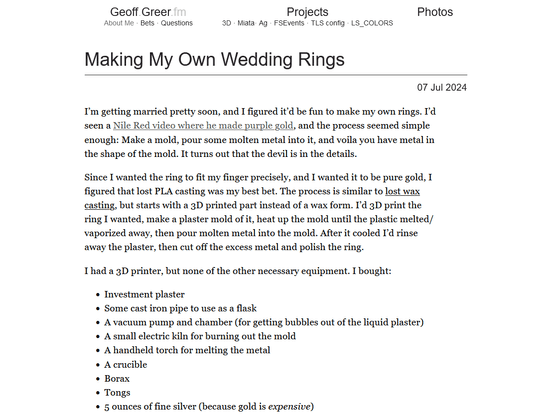

Geoff Greer's site: Making My Own Wedding Rings

https://geoff.greer.fm/2024/07/07/making-my-own-wedding-rings/

Greer, who ultimately aims to create a pure gold ring, first devised a method for making it himself. To create it, he used a method similar to '

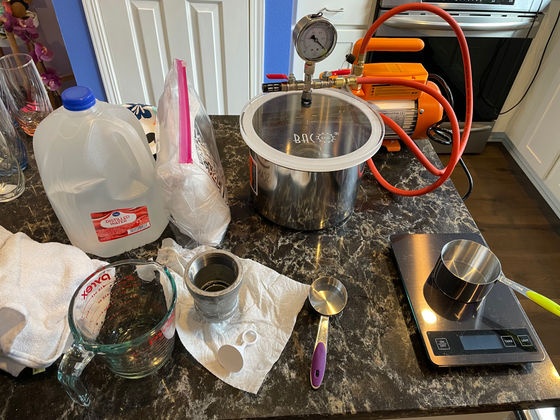

However, Mr. Greer did not have any casting tools, so he purchased plaster, a pot, a crucible, borax, and pure silver, which is the material for the ring.

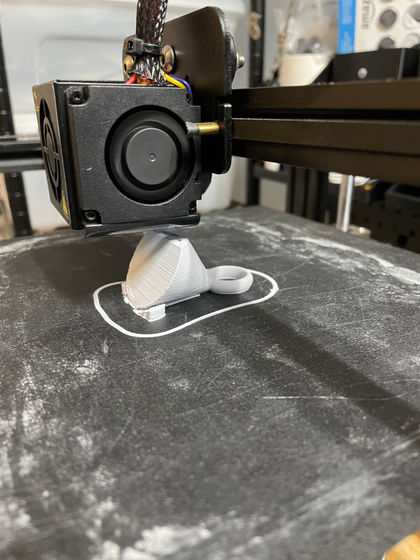

The actual process is as follows: First, 3D print the ring you want to create.

The ring made with a 3D printer is placed in the kiln and plaster is poured in. After that, it is put into a vacuum pump to remove air bubbles. The kiln is then heated to harden the plaster and burn and vaporize the 3D printing filament.

The borax-coated crucible is heated with a burner to melt the metal.

Once the metal is sufficiently molten, it is poured into a mold.

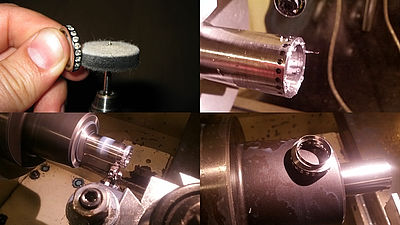

Once cooled and hardened, the plaster and excess metal parts are removed.

The metal in the shape of a ring looks like this.

The metal is polished and the ring is complete.

However, making a ring out of a single material caused the problem of 'air bubbles.' So Greer made the ring out of an alloy with a silver-gold ratio of 9:1. He also attached rubber to the steel plate during casting to seal it better and prevent air from getting in.

However, when heated, the rubber melted and could not seal properly, so the resulting rings were just as poor quality as the first test.

Greer then tested the ring by replacing the rubber with silicone rubber, and while the outside of the ring looked much better, it still had cosmetic defects on the inside.

Greer continued experimenting, heating the metal for longer periods of time and hammering the ring instead of polishing it smooth, until he was able to create a ring that matched his fiancée's taste, though it was less shiny than if he had polished it.

Finally, Greer used the same method to create a gold ring. 'The gold ring is very flashy, but very cool,' Greer said. 'Paying someone else to buy a ring for you is not very cool or romantic. On the other hand, when you look at the ring you've worked so hard to create, it reminds you of all the effort, trial and error, failure, setbacks, and successes you've made.'

Related Posts:

in Science, Posted by log1r_ut