A movie that produces elaborate mini knives from one bolt is open

In the world there are people who passionate on "to process something and create completely different things"Process aluminum foil into kitchen knife,Replace food wrap with kitchen knifeThere are also bizarre. A movie that men who are one of those vigorously process a single bolt that does not change anything to a clean mini knife is on YouTube.

I Turn a Stainless Steel Bolt into a Beautiful little Hunting Knife

A man looking for a bolt at a home center.

With one bolt in hand ......

Dash to checkout.

The purchased bolt is about 14 cm in length.

The male fixes the bolt across the vise and ... ...

I will cut off the hexagon head of the bolt with an electric blades cutter.

Turn it over halfway ... ...

Also cut off the other head.

The man was working like a deck facing the garden, with the sparks scattered vigorously.

Clean the head of the bolt as much as possible with a cutter.

Then, the head of the bolt almost became a columnar shape.

The man then prepared a gas burner and ignited with a lighter.

I will heat the head of the bolt.

When patting strongly with a burner, the head of the bolt became red.

Tap the heated bolt with a hammer.

When the head of the bolt got a bit flattened, I blown the cold bolt again with a burner.

When the bolt turns red ...

I clap the bolts with the hammer and then extend it even more flatly. The appearance of a male keeping knocking stainless steel bolt unnoticedly looks like a swordsmith who trains a blade.

The shape is a little irregular, but the head of the bolt has flattened a lot.

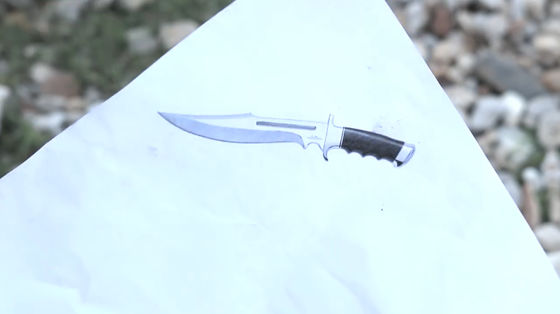

A diagram of a knife printed on paper is a projected completion diagram of a mini knife created from bolts.

The flattened part of the bolt is just the length from the tip of the knife to the tail.

Put the bolts in vice again ...

We will shape the shape of the bolt with a spiral file.

A man who scatters bolts little by little while scattering sparks.

Although there is roughness on the surface, it is much flat.

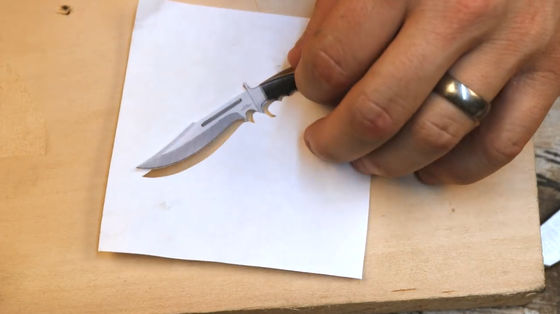

The man clipped out the knife of the completion drawing ... ....

I will put a forecast on the bolt and do the modeling.

It is a good idea to bolt through this shape.

Hold the spiral file again and scrape strongly.

As you cut gradually while changing angle, you can see that it gradually becomes a knife-like shape.

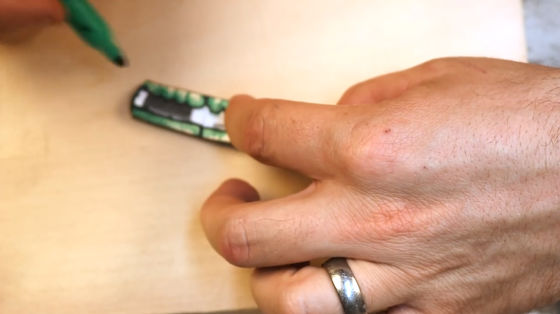

When shaving small parts, change the spiral file to a thinner type.

Finally, I was able to arrange it almost as shown.

From this state, a man who scrapes the finer details with a file for steel. It is a distracting task.

Next time we will use a very small rotating file to process the part of the handle.

A man who can proceed with very delicate hands.

Next, use a cork to press the knife against the motorized file to clean the surface.

The surface of the mini knife gradually becomes smooth.

Unscrew the threaded bolt part ... ...

We will apply more detailed processing.

When the shape is almost completed, polish the surface of the knife with paper file.

The facial expression of a man who grinds a knife with a serious looking face is serious.

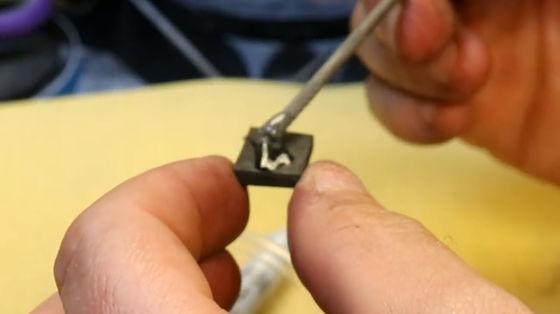

The next man took out is a square charcoal.

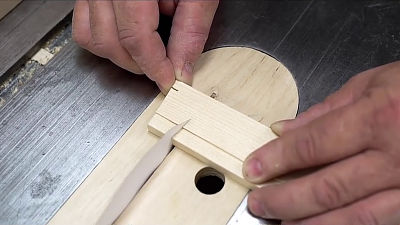

I cut the charcoal with an electric saw and cut out two small parts.

The parts will fit in the handle of the knife. As it will not fit as it is, I will scrape the parts.

Cutting out a bit with an electric file ......

Compare this with the handle of the knife and fine-tune the size.

I was going to scrape it over and over and finally I could fit the parts in the handle of the knife.

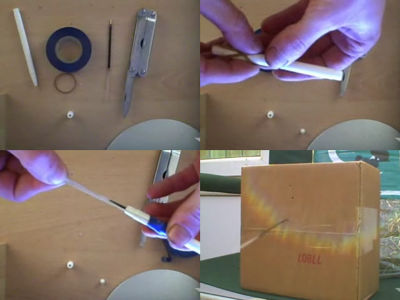

Next, apply the adhesive to the parts.

A man glue a part with a knife ......

I pushed it across the vise.

When the adhesive dries it looks like this. The parts of the handle are too big for the thickness of the knife, so it is in a state of slightly disgusting.

From this state, the file and the knife are put together together.

When the surface of the knife becomes smooth, a hole is made in the handle of the knife ......

Drive a metal screw.

A man who hits a knife again to an electric file.

I also sprinkle files carefully on the part of the handle.

Almost completed a mini knife. It is a very unbelievable finish to say that it was Bolt which was originally sold at the home center.

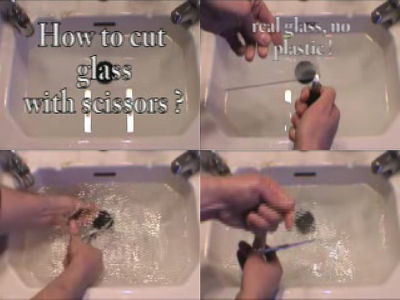

The man then fills the container with water ......

I took out the whetstone.

We set the grindstone and sharpen the blade of the knife.

Using a mini knife with sharpened blades, you can now cut men's hair. It is as sharp as a razor.

This is the finished mini knife at last. The surface has a beautiful gloss and it is wearing beautiful like Uttori.

The part of the handle is familiar with the knife without discomfort.

Saya made of leather made according to the mini knife ......

The mini knife fits perfectly.

Related Posts: