Why do artificial satellites have to be manufactured in 'clean rooms'?

Sparkling clean! --Why satellites are manufactured in clean rooms

https://www.ohb.de/en/magazine/sparkling-clean

Humans drop up to 600,000 pieces of skin from their bodies per hour, and it is said that 70 to 100 hairs are lost every day in healthy people. Also, for example, in the home, fine fibers are generated as dust by the friction of clothes, upholstered furniture, and carpet, and pollen and street dust enter when the window is opened and ventilation is performed. In this way, dust is always generated in the rooms where people are active.

Since artificial satellites cannot be maintained once they are launched into space, even the slightest stains on them during the manufacturing process can cause malfunctions. It is said that only one dust particle can interfere with the orbit of the artificial satellite. In addition, since general lubricating oil cannot be used in space, there is a problem that the mechanism of the artificial satellite does not work well due to dust, and if the sensor becomes dirty, the equipment can no longer be used. To avoid these problems, satellites will need to be manufactured in a clean room.

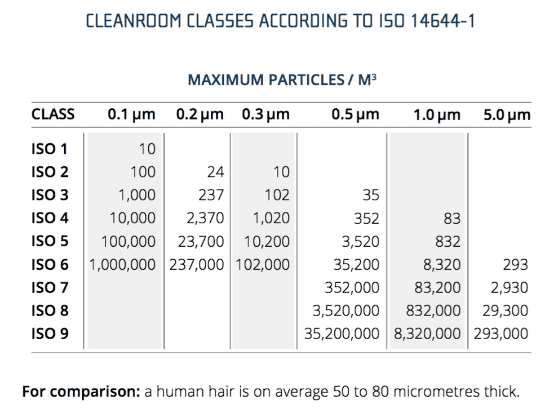

However, even if you say a clean room in a bite, there is a level of cleanliness. Clean room cleanliness is measured by the number of particles per cubic meter of air and is graded from ISO 1 to ISO 9 as follows: The cleanest ISO 1 is the presence of only 10 particles of 0.1 micrometer.

However, there are some clean rooms that are cleaner than ISO 1. The cleanest clean room in the world is the clean room of the Institute of Production Technology and Automation in Germany, which contains only one 0.1 micrometer particle per cubic meter of air. This means that it is 10 times cleaner than an ISO 1 clean room. The room tests devices and systems used in an ISO 1 environment, such as semiconductors and medical devices.

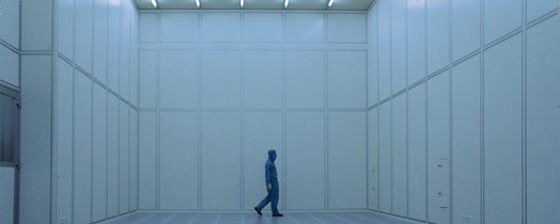

To maintain cleanliness, the clean room has minimal contact with the outside world. In order to maintain the same environment at all times, atmospheric pressure, temperature, humidity, etc. are all controlled and are not affected by the outside air. Ventilation is done through a special filter system and people enter and exit through airlocks.

In such a clean room, more than one-third of the pollution that occurs comes from humans. In Clean Ream, clothing itself is the source of particles, so people entering and exiting are required to wear special clothing made of synthetic fibers such as polyester. In addition, synthetic fibers are charged and easily adsorb particles, so antistatic treatment is applied. This also reduces the risk that products in the clean room will be damaged by unintentional discharge.

Like clothes, tools used in clean rooms are also specially designed, for example, pens are made up of ink with less risk of dirt and a sealed sleeve. The paint used for the walls also emits less particles, and the floor is made of synthetic resin so that there are fewer joints.

Related Posts: