Harvard University professor explains the situation where automobile makers and hardware makers are competing for chips due to the global shortage of semiconductors

The epidemic of the new coronavirus infection (COVID-19) and soaring crypto assets are causing a global semiconductor shortage, affecting the production of products such as automobiles, GPUs, and home appliances. Professor Willy Shih of Harvard Business School, an expert on chip and semiconductor supply chains, explains the 'chip competition' between automakers and hardware manufacturers that arose in the midst of this semiconductor shortage. ..

Why the global chip shortage is making it so hard to buy a PS5 --The Verge

https://www.theverge.com/2021/8/31/22648372/willy-shih-chip-shortage-tsmc-samsung-ps5-decoder-interview

Harvard Professor Explains Global Chip Shortage Affecting Industries | iPhone in Canada Blog

https://www.iphoneincanada.ca/news/harvard-professor-explains-global-chip-shortage-affecting-industries/

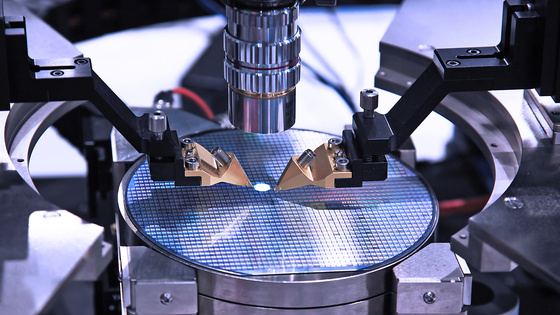

The global semiconductor shortage due to the temporary closure of factories due to the COVID-19 epidemic that occurred in 2020 and the increase in demand for GPUs for mining due to soaring crypto assets has continued since the beginning of 2021. In the month of the month, the lead time from ordering semiconductors to actual delivery exceeded 20 weeks . Due to this semiconductor shortage, manufacturers are being forced to respond, such as TSMC raising semiconductor prices by up to 20% and American automobile giant General Motors temporarily shutting down eight factories.

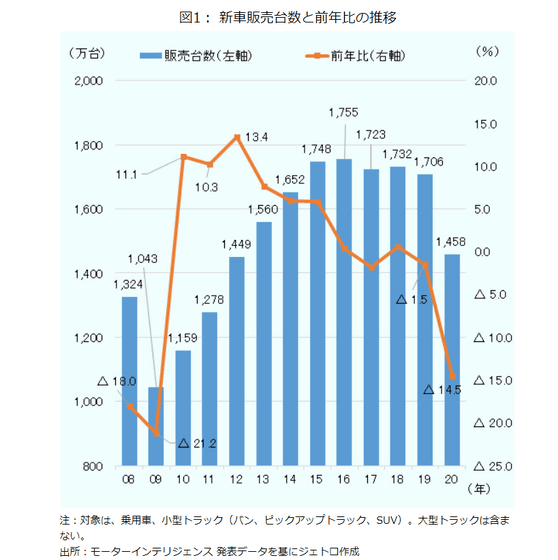

According to Professor Shi, who teaches about the supply chain of chips and semiconductors, the global semiconductor shortage originated from the Chinese automobile industry, which has more than double the annual production of 25 million units in the United States. The Chinese automobile industry has been suffering from a decrease in sales since 2018, but in early 2020, the COVID-19 pandemic hit directly and recorded a significant decrease in sales volume. After that, due to the spread of COVID-19, the number of units sold in the United States and Europe also dropped significantly.

Car sales and production in 2020 will decrease record-breaking due to the impact of the new corona (US) | Regional / Analysis Report --Overseas Business Information --JETRO

https://www.jetro.go.jp/biz/areareports/2021/6693a935851b2c72.html

In response to the record decrease in the number of cars sold, there was a movement among automakers to 'refrain from spending' because of the desire to avoid bankruptcy. The move resulted in worker layoffs, temporary factory closures, and 'semiconductor buying refrains.'

However, on the other hand, the demand for PCs, games, flat-screen TVs, home appliances, etc. was rapidly increasing due to the demand for nesting due to COVID-19. Under these circumstances, a phenomenon occurred in which semiconductors that automobile manufacturers refrained from buying flowed into the consumer electronics industry, but the number of automobiles sold recovered from around the summer of 2020. It is said that this semiconductor shortage was caused by an automobile manufacturer who hurriedly tried to buy back the semiconductors that were flowing in the home appliance industry.

Professor Shi said that not only automobile manufacturers but also the sanctions of Chinese companies in the United States and the accidents of a series of semiconductor companies contributed greatly to this semiconductor shortage. According to Professor Shi, many of the sanctions on Chinese companies in the United States came into effect at the end of 2020, creating a last-minute demand for semiconductors made in China, as well as the closure of Samsung's US factory due to a fire and record cold wave at the Asahi Kasei Electronics production center. The fire at Renesas' Naka factory, which accounts for 40% of the market share of automotive microcontrollers, had a major impact.

Under these circumstances, the “hoarding” carried out by each manufacturer is also one of the factors that accelerate the semiconductor shortage. If there are manufacturers who can stock up on semiconductors and manufacturers who can't stock up, manufacturers who can't stock up on semiconductors can't manufacture products, but manufacturers who can stock up on products continue to unilaterally increase their market share. Can be done. In other words, in the midst of a shortage of semiconductors, it can be said that the amount of semiconductors held is directly linked to the market share, so each manufacturer is continuing to place additional orders for semiconductors while making excuses for 'building a safe inventory.'

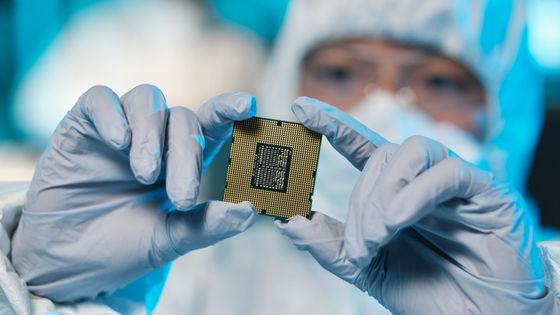

According to Professor Shi, the semiconductor industry and the automobile industry are taking a joint step under these circumstances. Until now, the semiconductor industry and the automobile industry had a stake in each other, so it was a kind of hostile, but with this semiconductor shortage, an automobile manufacturer who said, 'We have to become a strategic partner with a chip maker' has appeared. According to Professor Shi, 'Toyota has always taken this approach even before the shortage of semiconductors, and it was much better in this pandemic.'

As mentioned above, each semiconductor manufacturer is competing for semiconductors, but semiconductor manufacturers are increasing the allocation to automobile manufacturers at the request of the governments of each country, and TSMC, the largest semiconductor company, said, 'In-vehicle semiconductors increased by 60% from the previous year.' Professor Shi explains that 'GPU and game hardware are eating up' from this background.

Taiwan TSMC to increase production of automotive semiconductors by 60% in 2009 Cooperation with US: Nihon Keizai Shimbun

https://www.nikkei.com/article/DGXZQOGM21E2D0R20C21A5000000/

Related Posts: