Open source project 'MakAir' that can make a respirator for only 60,000 yen

In March 2020, a project to develop an open-source ventilator, 'MakAir, ' was launched to address the shortage of ventilators caused by the new coronavirus infection (COVID-19).

Accueil --MakAir

https://makair.life/

GitHub --makers-for-life / makair: The first open-source ventilator tested on human patients. Mass-producible at a low cost (~ 2000 €).

https://github.com/makers-for-life/makair/

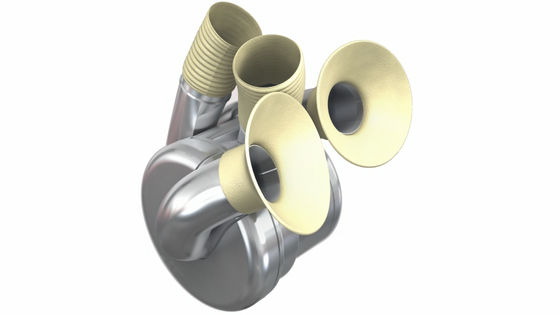

This is the main body of the latest version of MakAir at the time of writing the article. Although it is a fairly full-scale respirator, the cost per unit is expected to be 500 euros (about 63,000 yen) or less. Also, in the case of mass production or when cheap ready-made products can be incorporated, it seems that it may be possible to make it for 100 euros (about 12,500 yen) to 200 euros (about 25,000 yen) per unit.

Here's how to make MakAir.

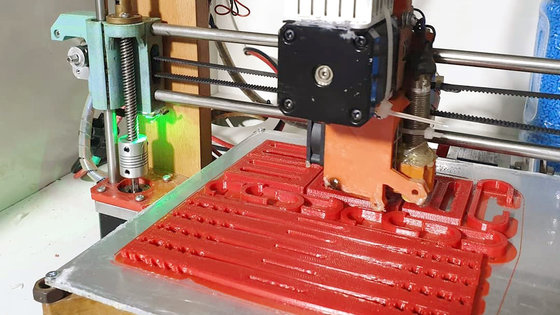

◆ 1: Prepare all parts with a 3D printer

For manufacturing MakAir,

The parts to be printed are as follows.

・ Blower: 1 piece

_m.jpg)

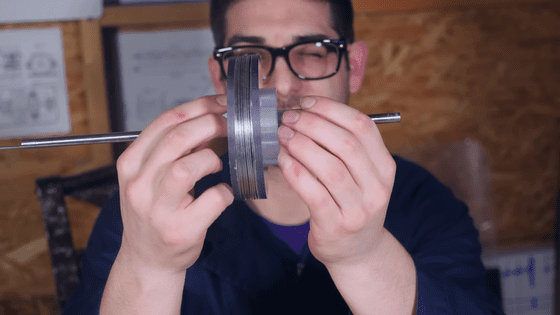

・ Pressure valve: 2 pieces

_m.jpg)

・ Oxygen mixer: 1 piece

_m.jpg)

・ Mechanical filter box (intake / exhaust): 1 piece at a time

_m.jpg)

・ Pressure connector (for blower, for oxygen, for no pressure, for pressurization): 1 for each

_m.jpg)

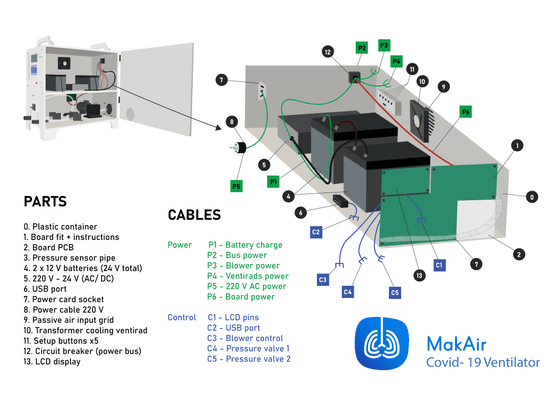

◆ 2: Assemble the electronic device

Electronic devices are roughly divided into the following two types.

・ Motherboard

・ Control unit screen

The control unit uses a Raspberry Pi 4 connected to the Raspberry Pi Touch Display .

◆ 3: Software

Once the mechanical parts and electronic devices that are the hardware of the ventilator are ready, the next step is to install the software. There are two types of software, 'firmware' and 'control unit runtime'.

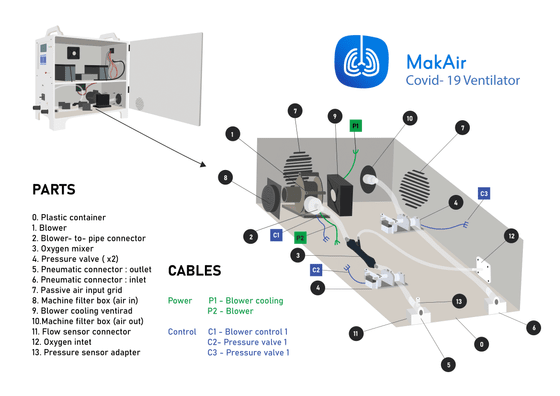

◆ 4: Assembly

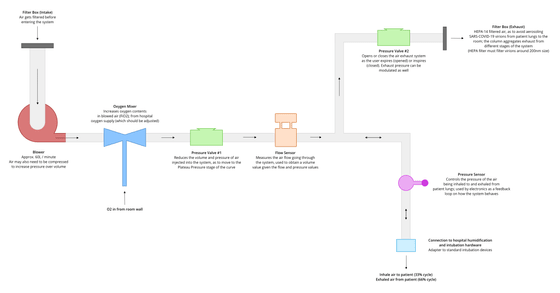

Finally, assemble all the components. The connection method of the air valve etc. is like this ...

How to assemble the main body is as follows.

With the cooperation of more than 200 experts from around the world, mainly in France, MakAir has completed clinical trials in just one month since its inauguration in March 2020, and has already been approved by the French health authorities. matter. Even in 2021, the MakAir team continues to improve the ventilator.

Related Posts:

_m.jpg)