Porsche realizes 10% weight reduction of piston and performance improvement by utilizing 3D printer

Porsche has been using 3D printers for production

Porsche Press releases: Innovative pistons from a 3D printer for increased power and efficiency-Porsche AG

https://www.porsche.com/international/aboutporsche/pressreleases/pag/?pool=international-de&id=596811

Innovative pistons from a 3D printer for increased power and efficiency

Porsche Found a Way to 3D-Print Lightweight Pistons That Add Even More Horsepower-The Drive

https://www.thedrive.com/tech/34775/porsche-found-a-way-to-3d-print-lightweight-pistons-that-add-even-more-horsepower

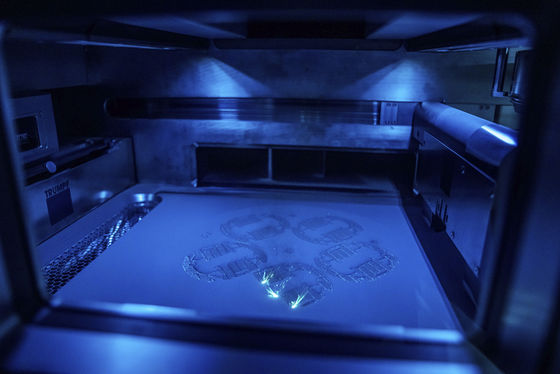

With 3D printing technology, it is possible to manufacture a piston with a structure that is optimized for the applied load. This piston is 10% lighter than the forged mass-produced product, and the piston crown has an integrated closed cooling duct that could not be attached by the conventional method.

The aluminum powder, which is the source of the material, was procured from a German component maker, Mare, and the 3D printer used was from TRUMPF. Additive molding technology ' laser metal fusion ' is used.

Made piston

Frank Eckinger, who specializes in 3D printing technology in the power unit pre-development department, said, ``Thanks to the new lightweight piston, we will increase the engine speed while simultaneously lowering the temperature load of the piston and optimizing combustion. 'You can get an additional 30 horsepower from a 700-horsepower biturbo (twin-turbo) engine, which improves efficiency,' he added.

Related Posts: