A movie that disassembles 'vice power' which was a sabbaby apart and cleans it and revives just as brand new is too pleasant

Even though it looks like it got old and broken, it is common that the function of the machine is restored by actually doing maintenance. It seems that it was made about 30 years ago, 360 degrees It seems that it seems to have been decayed by a rustling service from anywhere from anywhere Looks like a tool " vise " is thoroughly disassembled up to parts unit, cleaned shiny, just like a brand-new state You can see stunning techniques in movies that restore to.

Rusty Deadlocked Vise - Perfect Restoration - YouTube

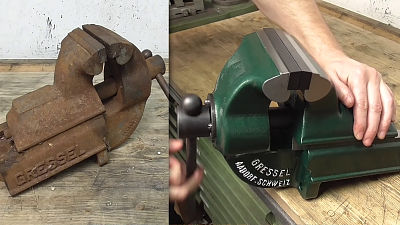

The restore this time is the vice of Swiss tool maker "GRESSEL".

According to YouTube comment section, it is confirmed that this type of vice was manufactured until 1991. A vice which was made at least 27 years ago was in a condition where the rust wonderfully floated, and it can not be thought that it can be used as it is.

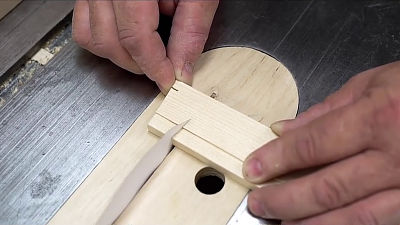

At the base of the shaft that turns the steering wheel, the semicircular parts that should have been the main body has been eliminated for each screw.

The mouthpiece part sandwiching the part is also rusty brown.

Originally it moved to the front and back and the part of "jaw" which sandwiching the part is also completely fixed and it does not even work as a bicycle.

WD-40 of anti-rust lubricant was taken out here. In Japan, as well as KURE 5-56 , it is a common spray sprayer at the site of machine maintenance, but compared to 5-56, which has a strong part-like color tone, the WD-40 has the characteristic of "lubricant not to cause rust" It is. So, actually it seems that the effect is better if you use 5-56, but it seems to be difficult to obtain in Switzerland where workers live.

Spraying WD - 40 on vice that is rusting ... ...

I tried to hammer with a hammer and try to disassemble, but no stubborn rusty teeth at all.

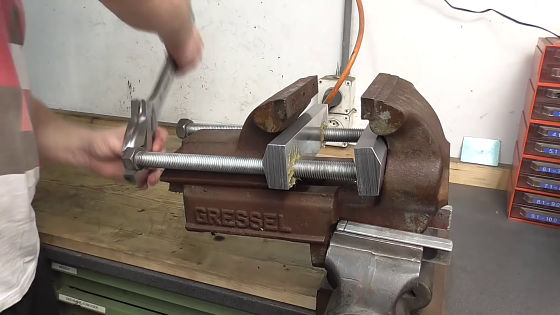

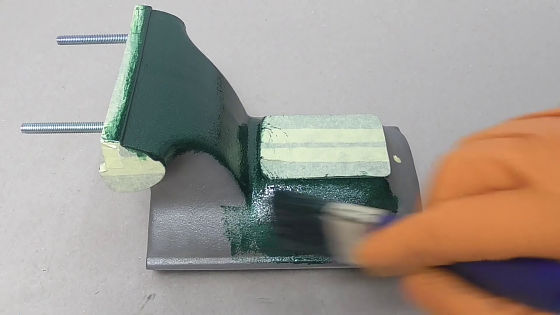

Since it can not be helped, I will try separating by using a huge two screws and brute.

Separation of the movable part is over and the condition seems to be not bad if you check "sliding surface".

Loosen the screw with the impact screwdriver ...

Dismantle with hammer and punch.

In this way, we succeeded in separating all the parts.

Scraping debris and garbage on the surface ... ...

Dropped rust with a brush ......

Clean the dirt with detergent and water.

For the part that was flat finished, first prepare the surface roughly with gold fillet ... ...

Finish the surface with sandpaper wrapped around the block.

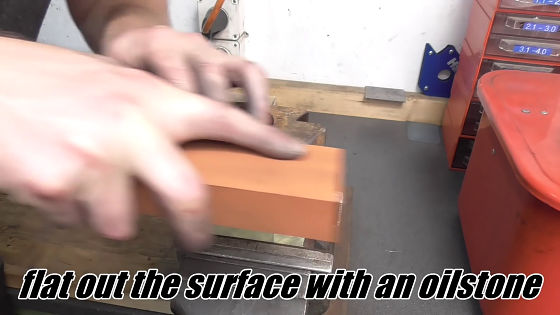

For places where smoothness is required, such as sliding surface, we will use an oil stone (oil grindstone) to draw a flat surface.

Even in the case of a screw part which is no longer usable, once work is done to re-screw the thread after re-drilling with a drill.

Aluminum tape was taken out for the next work.

In the next step, we will perform "sand blasting" which blows fine abrasive material on the surface of the metal with air. Although it will blow away all the dirt on the surface, it protects with the aluminum tape so as not to ruin the polished parts such as the sliding surface at that time.

Put it in a dedicated machine and spray it with an abrasive, it falls down while rust and dirt are seen ......

It revived to a shiny state like this.

Thanks to the aluminum tape, the essential sliding surface is safe.

As a tool to drop metal rust, there is what is called "P-Laser" which irradiates laser light to blow away the rust to a high temperature plasma state but it is not used in this work. The reason is unknown, but maybe there are also expensive equipment that is said to be "more than 5 million yen per unit".

Surprising laser cleaner that irradiates laser light and removes metal rust without attaching a single scratch and makes it beautiful - GIGAZINE

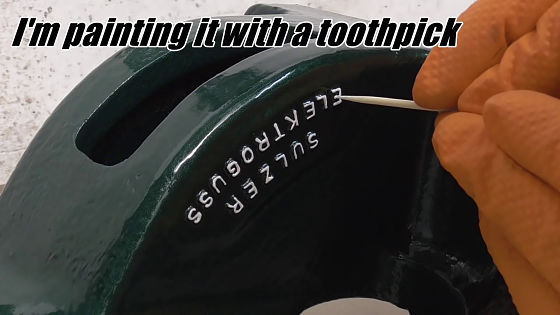

We degrease the surface, paint the green paint and do the chorus stop and finish.

Manufacturer name etc. Work fine parts using brushes and toothpicks.

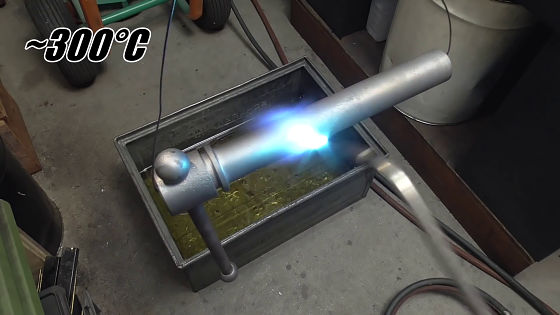

"Hardening" is performed on parts that require hardness. Heat it to over 300 degrees with a gas burner ......

Immerse in rapeseed oil "Jut" and carry out heat treatment.

The finish of the part is completed, and it reaches the assembled state afterwards.

To protect the moving parts, paint a lot of grease ......

Grease grease on the sliding surface and attach the moving part. I am about to return to the appearance of the day with all the strength.

Rotating the handle, the moving part closely followed with the throb ... ....

The vice which was superb and habitable was born just as brand new.

Coarse garbage was on the verge, a brown iron scrap ......

Resurrected as a beautiful vise of pickiness.

The base part is replaced with a new part of a slightly different type depending on the operator's preference. Restoration has been completed to a magnificently active vice power.

Related Posts: