Until a cutting board like a beautiful wood grain "parquet" is made

"Cutting board" making use of the beauty of wood is a popular tool for people who adhere to cooking tools, but Canadian manufacturer "Larch Wood"The cutting board to be produced is a product which can also be called a work of art which was processed so that the pattern of the annual rings of the tree will emerge on the surface.

Cutting Boards, Cutting Board, Chopping Blocks, Chef Blocks, Cheese Boards | Larch Wood Enterprises Inc, Cape Breton, Nova Scotia, Canada

http://www.larchwoodcanada.com/

The chopping board made by Larch Wood is characterized by the design where grain appears on the surface as follows. Such a rectangular cutting board ......

Round board with large and small sizes.

In addition, there is a lineup of design boards called "Tiger Stripe" that devised a combination of wood grain.

In this way, the cutting board of Larch Wood is a product that features designs that make use of tree rings. In the following movies, the production scenery of such a cutting board is introduced.

How to Make End Grain Cutting Boards | Où se trouve: Larch Wood - YouTube

A lot of logs stacked in a storage place. Larch Wood's cutting boards all begin with cutting such logs.

Set the log on a huge machine and cut the extra part.

Then, a rectangular square material has been completed.

In addition, this machine sliced square material into several boards. I think whether cutting this board to make chopping boards, in reality it is not so.

The sliced plate is placed in a huge drying oven, and it takes over 16 to 20 hours to drain extra moisture.

Squared material is sandwiched between boards and boards that are stacked in a tiny stack and devised to evenly dry.

When drying is over, the beginning of the processing process.

First cut to a predetermined length.

Next, finish the surface flat with an electric cannula called "planer".

After finishing the surface, cut the plate like wood into three thin bars this time.

A piece of board was cut into thin squared timber.

The dimensions of this square is a point. The length of the side is cut to become the "golden ratio" which is considered to be the most balanced.

An operator who stacks cut squares. It's not simply stacking trees.

While thinking about the balance of the wood grain, it seems that it is accumulating while calculating it so as to become the most beautiful appearance.

Once the way of stacking is decided, we will go through the process of applying adhesive and laminating the wood.

Sewing machine painted with adhesive was set on a special machine.

After loading a predetermined number, set iron frame on top ... ...

Using power tools, bond the wood while compressing the wood so as to pinch it from above and below.

The whole picture of the machine looks like this. The wood combined with each one of the rotating arms extending radially is set and it is made to be able to carry out the bonding process continuously.

Removing the bonded wood from the machine ......

In this way, a plate-like "laminated wood" which is a combination of thin rectangular materials is completed.

It is a laminated wood finished, but cut again thinly. This time it is cut to the angle of 90 degrees with the wood grain.

The cut wood was painted with glue and glued again on the table. What is different from the previous one is the direction of the wood grain, this time it is set so that the annual ring appears on the surface.

Using iron frame and clamp, firmly adhere the wood.

A single plate like this was completed. As the adhesive remains on the surface, it will enter the final finishing process from here.

Set the wood on the belt, work the surface flat ......

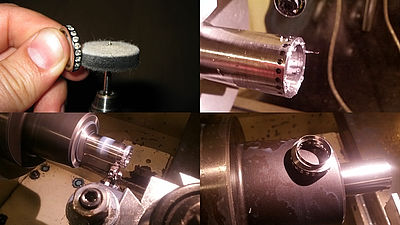

We will do "chamfering" to trim the corners of the board round and beautifully.

Press the hot burned iron on the polished wood.

A brand with the name of the manufacturer entered was engraved.

And further the surface is polished ... ...

A groove is dug around the board.

When processing is completed, the painting process will be carried out at the end. In this manufacturer, natural finishing using oil is done to make use of the beauty of wood grain.

Once the first painting has been dried over a day, we will do the second coating a second time. Since the tree structure is processed so as to appear on the surface, it seems that the surface will be strongly finished by soaking the oil into the tree.

Finally, install four rubber feet on the back of the board ......

If wrapped in wrapping film for packing it is completed.

Being beautifully wrapped, it will be shipped to dealership.

The surface of the finished cutting board looks like this. The grain is lined up in order, but if you look closely it is a testimony that everything looks different little by little using natural materials.

Cleaning, paint the wax attached to the cross like this.

"Since the wood fiber comes out on the surface, when the knife hit, the blade enters between the fibers, so the surface is not injured all the time".

Even if a knife scar remains on the surface in this way ...

It got almost inconspicuous when I stroked with my fingers several times.

In this way, Larch Wood produces chopping boards that take advantage of the characteristics of wood.

Like a Japanese "parquet work", the process of building up one board with time and effort is a splendid word. Larch Wood's products seem to be sold mainly in North America,American AmazonIn addition to being sold in Japan, amazon in Japan also made it possible to purchase parallel import goods.

Amazon.co.jp: Larchwood Sm Small Original Cutting Board by Larch Wood [Parallel import goods]: Home & amp; Kitchen

Related Posts: