TSMC plans to pre-produce 5nm process in April 2019

Semiconductor

TSMC to Start 5nm Production in April-EE Times Asia

https://www.eetasia.com/news/article/18100502-tsmc-to-start-5nm-production-in-april

TSMC: First 7nm EUV Chips Taped Out, 5nm Risk Production in Q2 2019

https://www.anandtech.com/show/13445/tsmc-first-7nm-euv-chips-taped-out-5nm-risk-in-q2

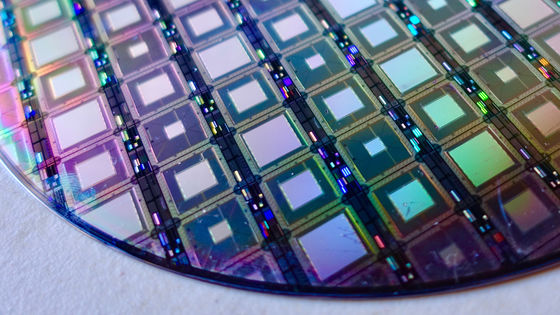

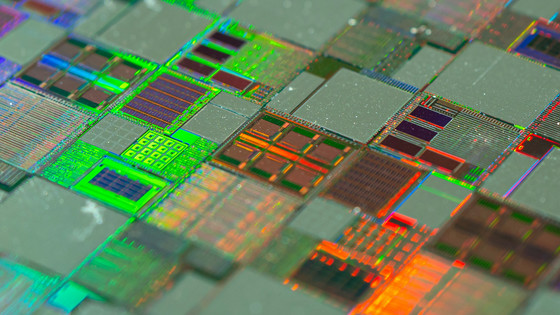

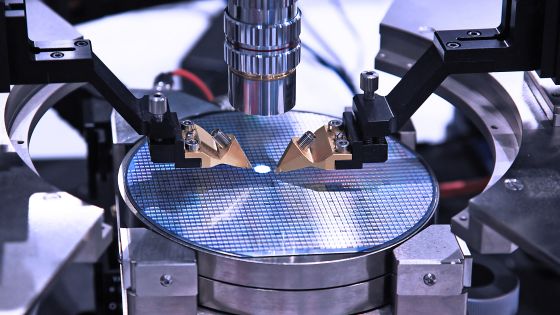

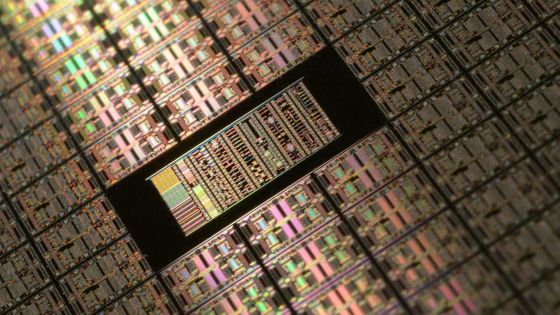

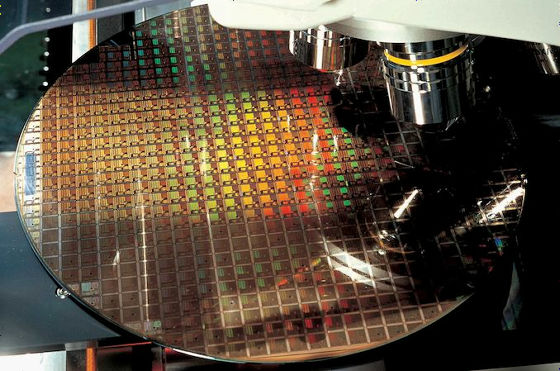

TSMC made two important presentations on extreme ultraviolet lithography (EUV) . One of them is that production of the second generation 7 nm process (N7 +) has started. TSMC had already started mass production of semiconductors in the first generation 7nm process (N7) in April 2018, but newly taped out the first customer chip with N7 +. The transistor density of N7 + is 20% higher than that of N7, and the power consumption is expected to be 8% lower and the frequency 6-12% higher.

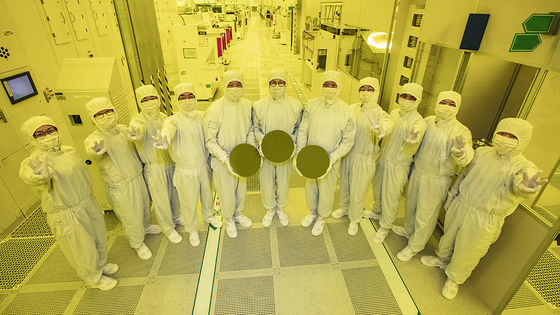

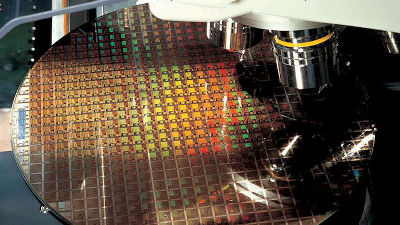

As another important announcement, TSMC has stated that it plans to carry out Risk Production (risk production) at 5 nm process (N5) as early as April 2019. “Risk production” is production that the semiconductor fab carries out independently as a preliminary test without receiving a chip production request from a specific customer. It is called because semiconductor fabs bear the risk of up-front investment when it is in the midst of finding out there is demand in the first place.

N7 + is just an improved process of N7, and it can not be expected to make a breakthrough in performance. On the other hand, with the progress of miniaturization N5, maximum 14 layers of EUV will be used, and the density of semiconductors will be greatly improved. Specifically, the transistor density will be 1.8 times that of N5, compared to the current mainstream N7 generation semiconductor chip, and semiconductor manufacturers will be able to reduce the design area by about 45%, and power consumption will be reduced by 20%, and frequency will be It is expected to be up 15%.

TSMC plans to start N5 risk production in April 2019, but generally it takes about one year from risk production to mass production for commercialization, so 2020 Q2 (April to June The semiconductor chip which adopted 5nm process is likely to be put on the market. In the case of Apple, which has entrusted semiconductor manufacturing to TSMC, it seems likely that the 2020 model iPhone will use a 5 nm 'A14 (provisional name)' chip.

In the semiconductor fab industry, where the introduction of EUV technology has become essential, the cost of launching a fab is rising. As a result, development competition is fierce, with rival Globalfoundries announced that it will stop production on the 7nm process . While it is unclear whether the semiconductor industry will remain strong by 2020, TSMC is poised to outperform rivals Samsung and Intel, taking the risk of massive upfront investment.

Related Posts:

in Hardware, Posted by darkhorse_log