How is eames Lounge chair & ottoman, immortal name furniture loved for over 60 years, made?

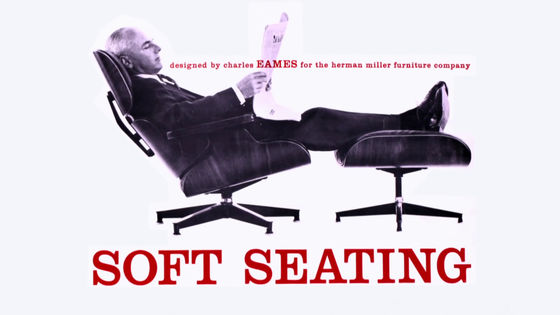

Interior designer representing the 20th centuryCharles & Ray EamesDesignedHerman MillerofLounge chairWhenOttomanIs a chair loved for more than 60 years since it was released in 1956. Explain how this lounge chair and ottoman are made and how to make various industrial products moviesBRANDMADE.TVIt is open to the public.

How an Eames Lounge Chair is made - BrandmadeTV - YouTube

"Eames Lounge Chair & Ottoman" was announced in 1956 from Herman Miller, a long-established furniture manufacturer founded in 1905.

Design is by Charles Eames and his wife Ray Eames. Designer designed a lot of buildings and furniture using state-of-the-art materials such as plywood and plastic which was rare in the first half of the 20th century, and was a designer who greatly influenced the design of industrial products of the 20th century.

When designing a lounge chair, Charles Eames is said to aim for "a comfortable feeling like being wrapped in a baseball glove used."

The lounge chair's luxurious appearance is strikingly impactful, and when it appeared as a TV drama props it also became a topic as a chair with an outstanding presence even in the screen.

There are many other kinds of chairs designed by Eames and Mrs. Although the chair made of wire, glass fiber, metal became popular as advanced, the most popular is the center of "Eames Plywood Chair "and Eames Lounge Chair & Ottoman. People may return to the style that they have been using since a long time ago.

The production of Eames Lounge Chair & Ottoman starts with processing the highest quality leather first.

Leather is spread cleanly on the desk, and marked with a red tape if a poor quality part, scratches, wormholes etc are seen even a little.

When you mark it, scan with a large scanner ......

The computer cuts the scratches and dirt off the cut pattern.

All leather cuts are done accurately by computer.

All the carved leathers are tied into cushion covers by sewing together by two female craftsmen.

High density urethane is used for the contents of the cushion.

The shape is shaped to fit on the back, the buttocks, the back, fasten the leather with the button to put the cushion tight, and then fill the urethane.

Especially since the position of the button greatly affects the beauty of the finish, it will be shaped while careful measurement is done so that there is no deviation.

What is used for pedestals and backboardsVeneerIt is a laminated plywood with combined. First, press the thrust plate to make it thinner.

Place the pressed veneer on a conveyor, apply adhesive on both sides, and alternately stack several sheets alternately so that the fibers of the wood are orthogonal.

Place the overlapped plate on a press machine and mold it at high temperature and high pressure.

The molded plywood is cut into a shape of a lounge chair back board, arm rest, ottoman by a computer controlled cutter.

The surface is polished and a hole is carved to secure the anti-slip rubber.

Polish the side gently ...

I attach the metal fittings for assembly.

A careful check by craftsmen is done in the warehouse for the seat and backboard of the completed chair. It is confirmed visually whether there are scratches or distortion, and the impact resistance test is carried out by adding pressure so that people do not break even if they sit.

Finally we will do the work of fixing the leather cushion to the pedestal or backboard. Fix the chair and ottoman's foot and cushion with screws.

It will not be shipped from the factory as soon as it is assembled. One man performs a final check just before shipment called "lock test".

The male is actually sitting on whether the cushion is securely fixed or not feeling comfortable to sit, weigh over 3 times and check it. Not only design, it is said that the commitment of craftsmen pursuing the highest quality so as not to impair the ultimate sitting comfort aimed at by the Eames couple are creating furniture that is loved for more than 60 years.

Related Posts: