Movie chasing after all the ping pong ball of table tennis how it is made

A classic table tennis as a hot spring inn's recreation is popular as a sport that anyone can enjoy easily. A movie capturing the manufacturing process of the factory's factory in the world's largest ping-pong ball maker is released to see how the ball "Ping Pong ball" used for such familiar sports table tennis is produced.

Pingsider | How Table Tennis Balls are Made - YouTube

How is the ping pong ball of table tennis made by all means?

A factory in DHS (Double Happiness Shanghai), the world's largest ping-pong ball manufacturer, in China that makes table tennis the de facto national sports.

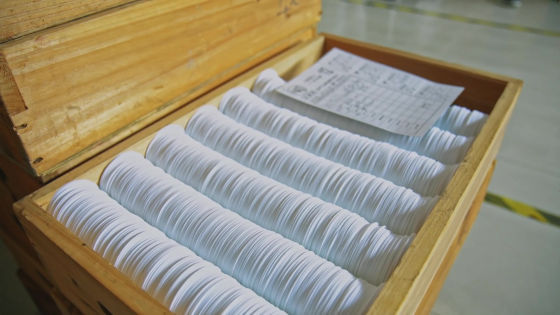

Raw materials of ping-pong balls are kept in the warehouse.

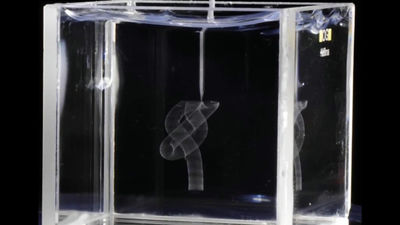

This is a plastic sheet on which ping-pong balls are based. It was once made of celluloid, but the recent ping-pong ball has been changed to plastic.

Plastic sheets are weighed one by one by hand.

Sheets outside the standard are excluded.

In step 1, "Shaping"

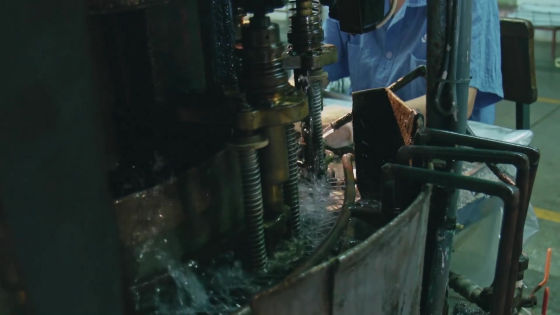

By extruding with such a machine, the seat is molded into a hemispherical shape.

It is said that it prevents the creation of a crack by attaching it to hot water of 40 degrees.

The seat changed to a hemispherical cup.

Step 2 is "Edge Trimming"

The hemispherical sheets stacked ... ...

When sent out one by one with a special machine ......

The part of the edge is cut with a cutter while rotating.

The edge was cut off beautifully, it became more like a hemisphere.

How to make it close to a sphere is a trade secret.

In step 3, "Glueing"

Fitting two cups in a mold ......

The machine fitted exactly two hemispheres and became spherical.

Through piping ......

You will be gathered.

Finally the spherical ping-pong ball is kept for 15 days in a warehouse at 45 ° C to 50 ° C until it stabilizes. In the case of conventional celluloid balls, it took 60 days, so it was said that the period was shortened by becoming a plastic ball.

"Quality check"

Finally the process of quality check. It is human being to check.

The DHS checks that the quality check by the double check system is done.

Quality check has 5 steps. The first step is to check the surface and joined parts in the state of lighting.

The ping - pong ball on the right means that the joint is not uniform.

Balls that could not clear the quality check are discarded.

Next, a rolling test called "VEEP".

Rolling a ping-pong ball from a special machine ......

Check if it rolls straight. Other than the ping-pong ball rolling within a certain range, it is sifted.

The third step is to check "hardness".

Use a special machine to check the hardness of several places.

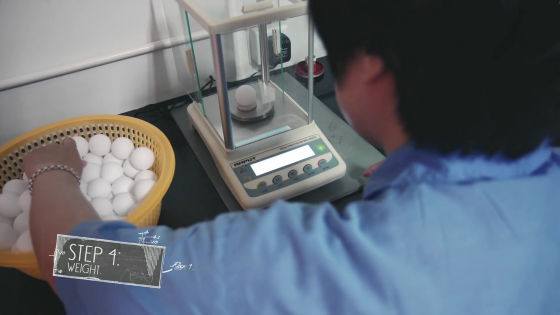

The fourth step is to check "weight".

It checks whether it is within the range from 2.68 g to 2.76 g.

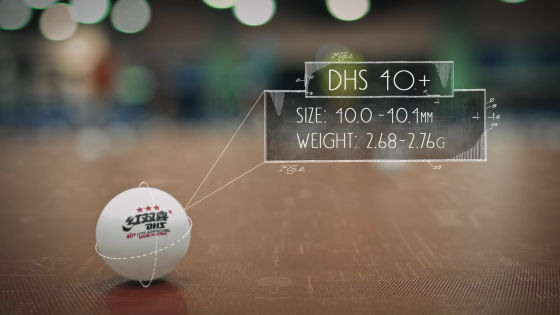

Finally check "roundness".

The small size in units of 0.01 mm is checked.

Mr. One Riotin who has experience of three times world champion said, "By changing from celluloid balls to plastic balls, the accuracy of ping-pong balls has increased and play stability has increased," said DHS's ball accuracy We are giving a certificate to the height of.

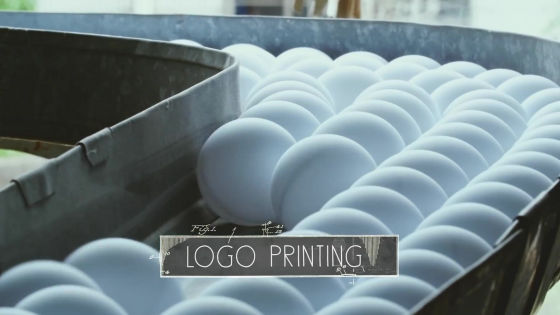

After clearing all the quality checks, finally the logo printing work.

A machine that can print at once in six balls is used.

The red letters are printed first ... ...

Next, a black surplus logo was printed.

Thus the ping-pong ball is completed.

Packaging work is fully automated.

It is said that 600,000 ping pong balls will be shipped a day.

Not only as a sports sports but also a table tennis loved by many people as entertainment is a ball game that anyone can easily enjoy ... ...

Production of ping-pong ball seems not easy.

Related Posts:

in Video, Posted by darkhorse_log