How is a Lego block made?

It is very popular as an assembly toy, and it is a LEGO block that can make various things. You can see how the block itself is made with photos and movies.

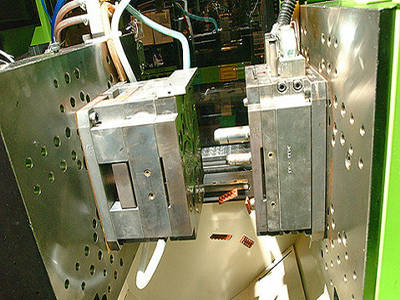

Details are as follows. The Lego block produces 15 billion parts each year. The material of the block is a granule of synthetic resin called acrylonitrile butadiene styrene (ABS). It is also a synthetic resin with high strength and impact resistance, which is also used for automobile interior.

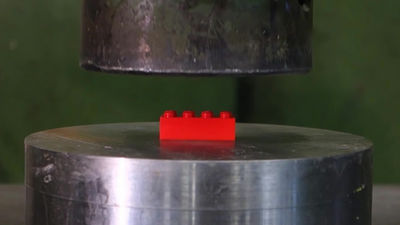

Put this grain in a molding machine, melt at 232 degrees Celsius temperature and pour into mold. Then it compresses with a force of 25 tons to 150 tons and makes it into a block shape. It seems that there are as few as 18 defective products in the Lego block per million, but it seems to be the power of this strong power.

The molded blocks ride on a belt conveyor and are conveyed while being cooled. It will be classified according to color and size when it is solidly cooled.

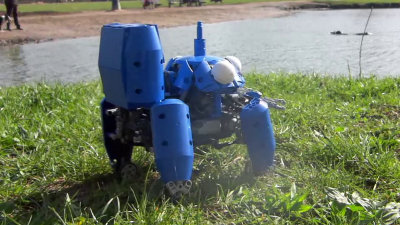

Labels are attached to the box filled with blocks by their contents, and the robots organize and stack them. And it is issued when it becomes necessary as a set.

Other photos and detailed articles below.

The Making of a LEGO Brick | BusinessWeek

The following sites can see these stages in order. It is small, but there are movies too. It seems quite amazing to see molded blocks emerge.

Making of a Brick

If you think that you are building an aircraft carrier or a difference institution with a block made like this, there are things that are deeply emotional.

Related Posts:

in Note, Posted by darkhorse_log