BMW invests in "Solid Power", a next-generation solid battery development company with two to three times the capacity of conventional BMW

ByDushan Hanuska

Automotive manufacturer BMW announced that it will invest in the start-up "Solid Power" to develop next-generation automotive battery technology in the US to advance efforts to realize a high-density solid battery.

BMW invests in solid-state batteries with '2-3 X' energy capacity for next-gen electric cars | Electrek

https://electrek.co/2017/12/18/bmw-solid-state-batteries-next-gen-electric-cars/

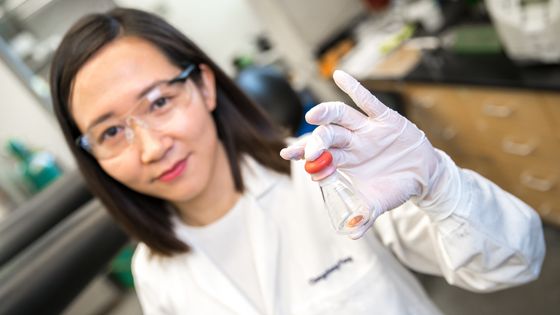

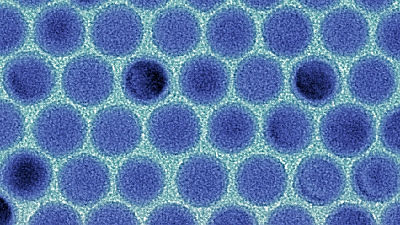

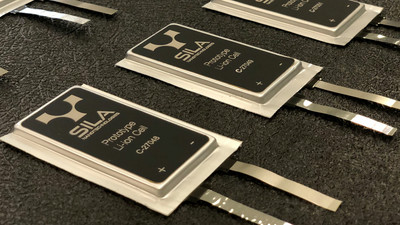

Solid Power BMW announced cooperation is a startup born from the laboratory of the University of Colorado at Boulder. The company aims to realize it is a high density battery that has 2 to 3 times more electricity stored than a general lithium ion battery, and its mechanism is a cathode (cathode) with extremely high electric capacity and also here A lithium metal anode (anode) with large capacity is combined with a separator with high ion conductivity. This battery not only has a large capacity but also a high safety point. Inorganic materials are used for all materials, and flammable liquids are not used in the body, so there is a merit that it is not related to the risk of lithium ion batteries that they ignite and burn up sharply.

Solid Power has received support from a number of companies, but this time it is the first time that it receives capital from major automakers. "The collaboration with BMW will further advance the innovation of solid-state batteries in the future," said Doug Campbell, CEO of the company, in cooperation with BMW, limiting the limits of EV- I am looking forward to breaking through. "

Solid Power

http://www.solidpowerbattery.com/

In the case of EV running with electricity as the energy source, the performance of the battery that keeps its energy is extremely important. Sufficient performance is achieved even with existing lithium-ion batteries as long as it supplies large capacity and stable electric power. However, if elements such as "light weight" and "safety" are added here, lithium ion batteries It is a situation in which it is inevitable to say that the challenges are left in the two.

The weight of the battery affects the running performance of the vehicle in all respects. In the world's best sold EV "Nissan LEAF", the weight of the car is about 1800 kg and the battery installed in the vehicle is about 300 kg. As a commercial vehicle, "Tesla Model S" which carries a very large capacity battery is said to be about 2100 kg in weight, and it is estimated that the weight of the battery is about 700 kg even if it estimates less. As the weight of the vehicle is lighter, the cruising distance is extended and the "electricity cost" is improved, so there are merits in light weight reduction in various ways, but huge and heavy batteries are a hindrance in EV. Also, although the heaviest part of a non-EV body such as a gasoline car is the "engine" itself, considering the situation where the weight is about 250 kg even if it is a large engine of the V8 engine class, how is the battery in EV's vehicle weight You can see whether it occupies a large part.

Under such circumstances, solid-state batteries with power density up to 3 times higher than existing lithium-ion batteries attract much attention. This trend is already known to automobile manufacturers all over the world, and Toyota is also developing all solid-state batteries and it is said that it will announce EV with all-solid battery within the next few years. In addition, on 13th December 2017, announced that Toyota and Panasonic will begin discussing collaboration of automotive prismatic battery business.

Toyota and Panasonic start discussing collaboration of rectangular battery business for in-car | CORPORATE | Toyota Global News Room

https://newsroom.toyota.co.jp/jp/corporate/20243459.html

The all-solid-state battery to replace the existing lithium-ion batteries will gather naturally a great deal of attention, but in fact is still in the research stage, it is also important to understand that it takes some time to practical use. We are still challenges due to the portion which is not established technology left, and during early even realized cost becomes expensive, to achieve the cost competitiveness of the same level as the lithium ion battery Is far from the situation. In addition, existing lithium-ion batteries still have "elongation margins" left, and it seems that there are still elements to separate all-solid batteries such as weight reduction and cost reduction.

Related Posts: