Technology has been developed to increase the capacity of lithium-ion batteries by up to 70%

With the spread of smartphones and electric vehicles, demand for

To Boost Lithium-Ion Battery Capacity by up to 70%, Add Silicon - IEEE Spectrum

https://spectrum.ieee.org/energy/renewables/to-boost-lithiumion-battery-capacity-by-up-to-70-add-silicon

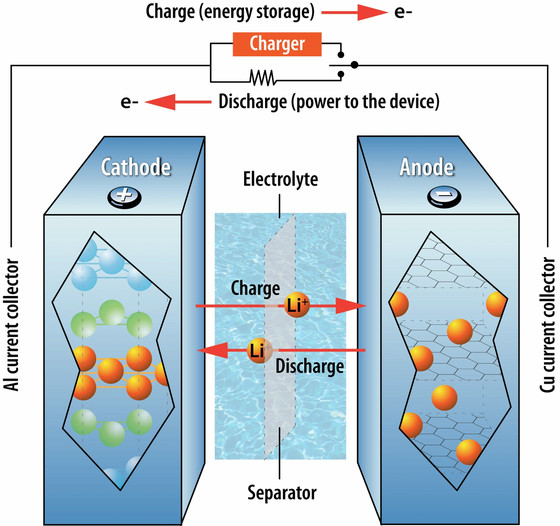

Lithium-ion batteries have a layered structure in which both the positive and negative electrodes are layered. When a lithium-ion battery is charged, electrons move from the positive electrode to the negative electrode, and lithium ions pass through the electrolyte and accumulate at the negative electrode, creating a potential difference. Conversely, during discharge, electrons move from the negative electrode to the positive electrode, and at the same time, lithium ions pass through the electrolyte and move from the negative electrode to the positive electrode. In other words, the more lithium ions are stored in the negative electrode, the more energy can be stored.

by

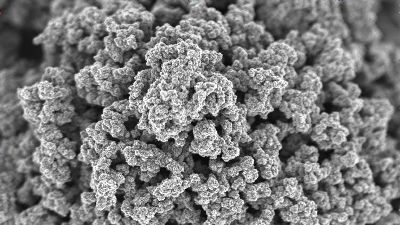

The negative electrode of lithium-ion batteries used in smartphones, notebook PCs, and many electric vehicles is made of graphite . Inside the negative electrode of a battery, lithium is stored in the form of LiC 6 surrounded by six carbon atoms.

On the other hand, lithium ions also combine with silicon to form Li 15 Si 4 . While carbon has 6 atoms and can only secure 1 atom of lithium, silicon has 4 atoms and can secure 15 atoms of lithium, and is expected to be a material that can store lithium in the negative electrode more efficiently than graphite. Ion battery developers have been researching ways to use silicon as the negative electrode material instead of graphite.

However, silicon negative electrodes have the disadvantage that their volume expands and deflates each time they are charged and discharged. Therefore, repeated charge/discharge cycles cause the negative electrode to collapse, causing the battery to wear out very quickly. As a solution to this drawback, technology has been established that combines carbon and silicon to achieve both capacity and lifespan, and in fact, the lithium-ion battery developed by Tesla, led by CEO Elon Musk, in 2016 is a mixture of carbon and silicon. A negative electrode is used. Even so, the silicon content in the negative electrode is low, and the current situation is that a complete silicon negative electrode has not been completed.

California startup

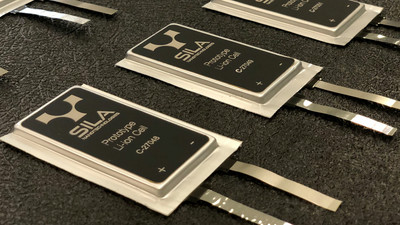

Gleb Yushin, a professor at the Georgia Institute of Technology and co-founder of Sila Nanotechnologies, said, ``Using Sila Nanotechnologies' proprietary anode material, we can increase charging capacity by as much as 20-40% while reducing electrode thickness. 'It can now be made up to 67% thinner, and the charging speed can be up to nine times faster than before,' and revealed that it is scheduled to go into commercial production in 2019.

Also, another California startup, Enovix , imports manufacturing technology from the semiconductor industry and claims to have almost succeeded in developing a large lithium-ion battery for cars equipped with silicon electrodes. Enovix uses a three-dimensional cell structure that stacks silicon wafers, plated metal foil, and ceramic layers, and claims that it can significantly improve performance without changing the overall shape of the battery.

'Depending on the application, we expect battery capacity to increase by 30-70%,' said Ashok Lahiri, co-founder and chief technology officer at novix. IEEE Spectrum argues that if Enovix's battery is commercialized, it will shake up the entire lithium-ion battery industry.

Related Posts: