Development director comment on how much attention the Surface Pro 3 is designed

An event held in Chicago, USA from May 4 to May 2015 "Microsoft Ignite"so,"Surface Pro 3How was it born? "The product manager of Surface makes a presentation. From the presentation, you can see how Surface Pro 3 is designed to stick to it.

Building Microsoft Surface Pro 3 | Microsoft Ignite 2015 | Channel 9

Speaking about the hardware design of Surface Pro 3, Mr. Vinito Subera of Surface team project manager.

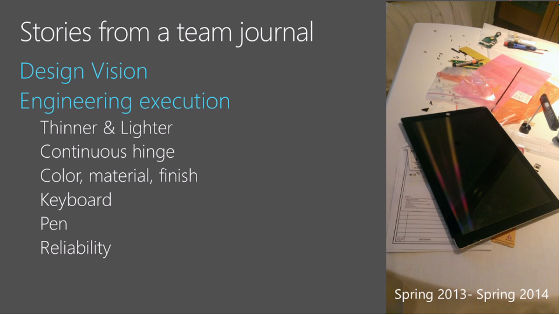

In the design concept relating to the hardware of Surface Pro 3, "thinner and lighter" is emphasized. The photo on the right is Mr. Su barra's desk, and he seems to be using Surface Pro 3 even in his normal work.

In order to have the user experience the best, Surface Pro 3 sticks to the detail design to the best.

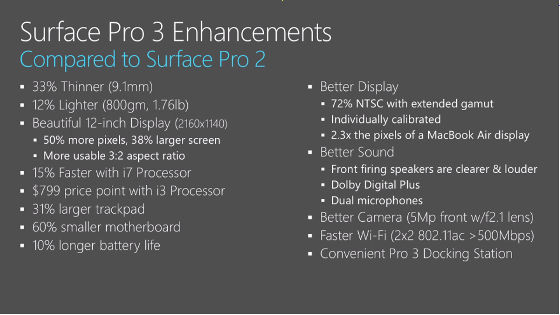

Surface Pro 3 with 33% thinner, 12% lighter, 1.5 times higher display resolution and 72% higher battery drive time than Surface Pro 2 with Surface Pro 2 as a benchmark and previous surfe Pro 2 as a benchmark. By adopting a high speed CPU of 15%, we are overwhelming Surface Pro 2 in the catalog specifications.

Surface Pro 3 has been reduced in weight even though the footprint is larger than Surface Pro 2.

In creating Surface Pro 3, the points emphasized by the creator are "Performance", "Schedule", "Cost effectiveness", "Manufacturability" .

I will move on to talk about specific product design. In order to pursue "thinner and lighter", magnesium alloy is used for the enclosure.

Working accuracy of magnesium alloy cut out with special CNC machine is superb level.

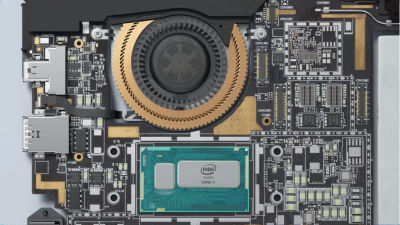

Comparing the parts layout of Surface Pro 2 (left) and Surface Pro 3 (right) is like this. Surface Pro 2 has a motherboard and heat source at the top of the main unit, while a battery at the bottom is located, while Surface Pro 3 arranges each one on the left and right. Especially, the fan that cools the CPU becomes one, and the length of the heat pipe that surrounds the fan is also short, which is characteristic. It is said that this layout realized a dramatic thinness of 9.1 mm.

The white part on the left of the screen is a battery. Of course the ultra-thin battery is dedicatedly designed. Also, the motherboard on the right side of the screen is also 60% smaller than Surface Pro 2.

The 4th generation Intel Core i7-4650U is installed in the CPU.

A motherboard designed to fit in space-saving is a phenomenal high density.

A golden heat sink distinctive around the fans. This fan structure is the secret that greatly improves the cooling performance of Surface Pro 3.

Surface Pro 2 adopted air flow (air flow) that takes in air from the left and right and waste heat from the hinge part.

In contrast, Surface Pro 3 has a special structure that takes in a large amount of air from the left side of the hinge and feeds air to various places by the fan so as to discharge it from the four slits and cool it.

A fan of special design to disperse the air. A circular heat sink is also designed to enhance cooling efficiency to detail.

By visualizing the air flow, the optimum condition is being discovered.

It is in the newly developed cooling system that Surface Pro 3 can operate stably without freezing even if high performance CPU is confined in an extremely thin housing.

Next is a story of a kickstand that can adjust the angle steplessly, which is a major feature of Surface Pro 3.

In Surface Pro 3, which emphasizes mobile performance, take it out to various places and investigate the feeling of use. She said that he tried to recreate the economy seat of an airplane and checked its comfort.

Thanks to the newly designed hinge that can adjust the angle linearly.

Make a hinge model of huge size and test the range of motion and durability.

The black part of this model is a part that is extremely important for durability.

The hinge examines which part of the kickstand is pressurized when moving the kickstand, and grease is painted accordingly. It seems that we have found a factory that can produce parts as expected in China as a result of seeking procurement of parts and manufacturing plants, pursuing the best use feeling such as smoothness and reasonable response.

Surface Pro 3, by adopting this newly designed hinge ......

It is now possible to fix to a free angle up to 150 degrees. The cost of developing the hinge is about 7 million dollars (about 860 million yen).

A quiz was issued on the way. "Have you tied up with any sports car maker" McLaren "" Porsche "" Lamborghini "to make Surface Pro 3?"

The audience at the venue talked about various answers, but the correct answer is Porsche. It seems that he co-worked with the Porsche process of painting.

Hinges made by studying research and ... ...

By high quality painting ......

The user experience is improving.

Surface Pro 3 has also been tested for impact resistance. It is said to be designed to function properly even under various adverse conditions such as falling and twisting, in high temperature and high humidity and in a bag.

Surface Pro 3 has newly designed dedicated keyboard type cover. By improving the stability by bending the magnet part, the angle is attached to the keyboard making it easy to type.

The important thing through the Surface series is Pen Tool.

The new Surface pen has decreased to 256 stages of pen pressure, but it improves writing comfort and battery life etc.

In particular, the algorithms have been reviewed so that latency can be reduced to prevent delays, parallax can be reduced to the limit and the pen can be drawn accurately on the touched part. It seems that not only in the PC itself but also on the Surface pen there are small invisible improvements.

·bonus

Surface Pro 3, which Microsoft made with particular attention to detail, Japan Microsoft will revise the price of Surface Pro 3 main unit and accessories from 1st June 2015 (Monday). Core i7 / 512GB models upgrade by 36,000 yen, all models will rise, so people who want it would be better to get it.

Price revision of Surface Pro 3 and accessories | News Center Japan

http://news.microsoft.com/ja-jp/2015/05/11/150511-surfacepro3/

Related Posts: